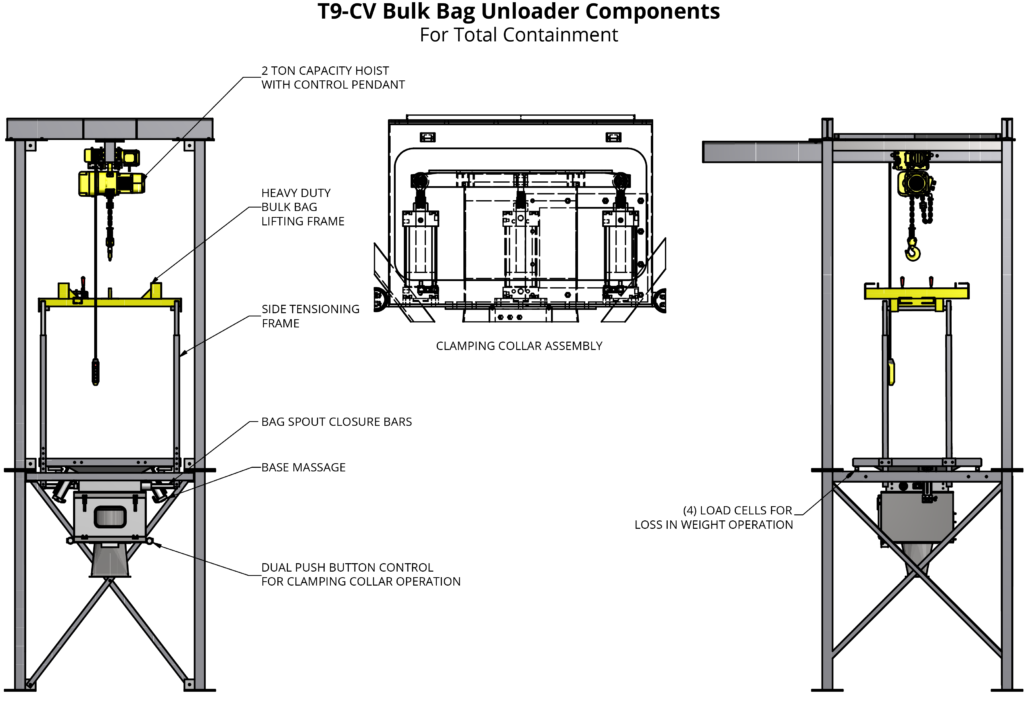

T9-CV Total Containment Unloader

System OVerview

Spiroflow has developed the T9-CV bulk bag unloader for applications where products handled in bulk bags are fine, powdery and invasive and total containment during unloading in necessary to prevent contamination of the local atmosphere. The T9-CV bulk bag and super sack unloader is also the natural unloading choice when your product is volatile, toxic or explosive.

It is important to ensure total discharge of product from the bulk bag when an invasive powder is being unloaded to prevent the escape of material when the emptied bag is removed. For this reason, the Model T9-CV has bag massagers at the corners of the bag as well as the base. An optional patented pneumatic bulk bag tensioner and the standard inner liner clamp prevent creases from forming during unloading which can trap residual material.

Height adjustment for bulk bags and super sacks of different sizes is provided as well as a lifting frame locator for correct alignment of the unloader with a process vessel or other equipment where the material is being unloaded. This feature enhances product containment.

Features

- Sealing device for bottom spout

- Variable height adjustment for different sizes of bulk bags

- Static grounding system with FIBC resistance monitoring

- Corner massagers

HOW IT WORKS & BENEFITS

The T9-CV Bulk Bag Unloader is designed for the total containment of hazardous, explosive or toxic products. It can be configured for unloading by volume or weight. It can also include an integral bag hoist.

BASE FRAMEWORK

The BASE FRAMEWORK is designed for the contained discharge of bulk bags. It is of all welded construction with a bag support dish that will accommodate any bottom-spout bulk bag. The bag spout passes through the middle of the dish where it can be accessed. The bulk bag provides an additional seal against the support dish for dust-free operation. Heavy-duty 3″ (80 mm) square steel tube frame is welded directly to the support dish.

CONTAINMENT ENCLOSURE

The CONTAINMENT ENCLOSURE is welded directly to the bulk bag unloader support dish complete with one door in front with polycarbonate viewing panels and a 4” (100 mm) diameter dust extraction spigot fitted to the rear of the containment enclosure for connecting to the client’s dust extraction system.

LINER CLAMP & DOWNSPOUT

The LINER CLAMP & DOWNSPOUT is positioned inside the containment enclosure. The stainless steel moving clamp and fixed position downspout facilitate the clamping of the bulk bag liner to the hygienic bag spout. The pneumatically operated clamp is retracted down to interface with the hygienic bag spout. The operation of the moving clamp is by a double button control box, 5” (125 mm) wide, mounted to the front center of the unit and below the containment enclosure.

This bulk bag unloader can incorporate a number of design options in order to provide maximum versatility and ease of use.

Process Steps

- A bulk bag of product is fitted with the Bag Lifting Frame.

- The operator lifts the bulk bag into place with a forklift.

- The Lifting Frame sits on the Side Tensioning Frame.

- The weight of the bag compresses the springs & the bottom of the bulk bag rests on the Support Dish.

- With the weight of the bag safely supported, the operator can now freely access the bottom spout of the bag.

- The operator will untie the outer bag and, if the bag is lined, he/she will place the liner into the hygienic bag spout and the outer bag over the hygienic bag spout chute.

- The operator will then press the two-handed safety switches to lower the retaining ring down onto the hygienic bag spout chute.

- Once the retaining ring is fully lowered, the inflatable ring will inflate and provide a dust-tight seal.

- The operator will then close the untie chamber door and actuate the spout closure bars to the open position. Material will begin to discharge from the bulk bag.

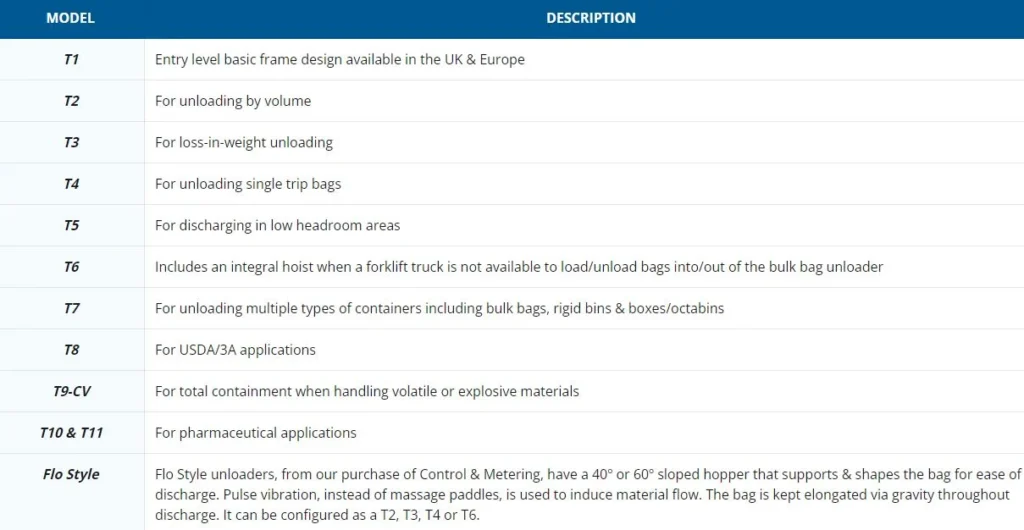

MODELS & SPECIFICATIONS

The T9-CV bulk bag unloader is one of several designs we offer. Features of our various models are typically mixed and matched to accommodate specific application needs. And, of course, we regularly build custom designs. Here is a list of our basic models. Your Spiroflow Sales Engineer will evaluate your needs and recommend the best configuration to do the job.