Déchargeur à confinement total T9-CV

Présentation du système

Le déchargeur de big bag T9-CV de Spiroflow est conçu spécifiquement pour manutention des matériaux qui nécessitent confinement complet pour éviter la contamination de l'air pendant le processus de déchargement. Ce système est idéal pour décharger en toute sécurité des contenus volatils, dangereux ou explosifs des sacs en vrac.

Pour obtenir un confinement complet du matériau, le T9-CV est conçu avec une pince de sortie à commande pneumatique, avec joint gonflable. La sortie du sac est scellée à l'équipement de déchargement en aval. Des interrupteurs doubles et un verrouillage de porte de sécurité obligent les mains de l'opérateur à être éloignées de la pince pneumatique pendant qu'elle est en mouvement.

Par ailleurs, le Le T9-CV peut accueillir des super sacs de différentes tailles avec sa fonction de hauteur réglable.

Caractéristiques

- Bec de sortie avec joint à commande pneumatique

- Réglage de la hauteur pour s'adapter à plusieurs tailles de sacs en vrac

- Système de mise à la terre statique avec surveillance de la résistance FIBC

- Masseurs d'angle

COMMENT CELA FONCTIONNE ET AVANTAGES

Le déchargeur de sacs en vrac T9-CV est conçu pour contenir entièrement les matières dangereuses, explosives ou toxiques. la conception permet un déchargement basé sur le volume ou le poids, et il peut être équipé d'un monte-sacs intégré. Voici les principales choses que vous devez savoir sur ce modèle.

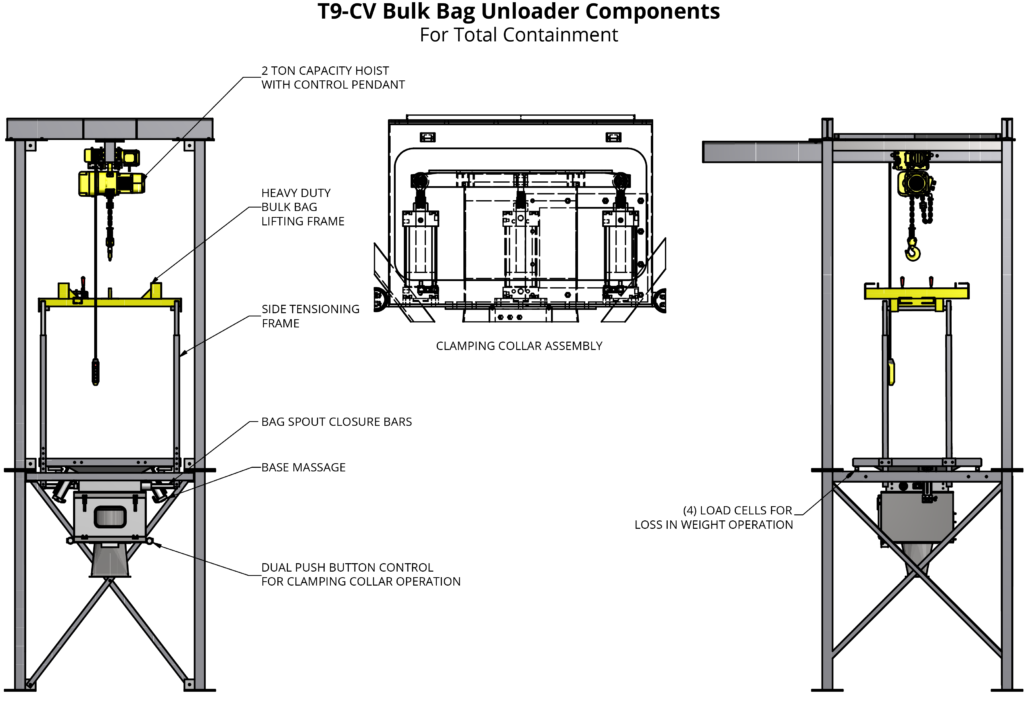

CADRE DE BASE

Le cadre de base est conçu pour supporter le poids total d'un super sac, construit à partir de tubes carrés de 3 pouces. la structure présente une conception entièrement soudée, et intègre un plat de support qui peut s'adapter à n'importe quel sac en vrac à bec verseur inférieur. Le bec verseur du sac s'étend à travers le centre du plat pour un accès facile. Le joint anti-poussière à membrane en caoutchouc crée une étanchéité supplémentaire contre les bords inférieurs du sac en vrac, garantissant un fonctionnement sans poussière.

ENCEINTE DE CONFINEMENT

L'enceinte de confinement est dotée d'un accès à charnière porte équipée de panneaux en polycarbonate pour visualisation. Le collier de serrage et le tuyau de descente sont contenus dans le boîtier. Une sortie d'extraction de poussière de 4 pouces (100 mm) est installée à l'arrière du boîtier, pour une connexion facile à une configuration d'extraction de poussière.

COLLIER DE SORTIE ET TUYAU DE DESCENTE

Situé à l'intérieur de l'enceinte de confinement, le système OUTLET CLAMP & DOWNSPOUT comprend une pince en acier inoxydable à commande pneumatique avec un joint pneumatique et un tuyau de descente stationnaire. Cette configuration permet fixation sécurisée du bec de sortie du big bag au tuyau de descente. Fonctionnant pneumatiquement, la pince est conçue pour se rétracter et se connecter au bec du sac propre.

Le mouvement de la pince est contrôlé par un boîtier de commande à deux boutons, mesurant 5 pouces (125 mm) de largeur, qui est positionné au centre avant de l'unité, juste sous l'enceinte de confinement. Nécessitant que la porte soit fermée et que les deux boutons soient enfoncés pour actionner la pince. Protéger les opérateurs de tout point de pincement potentiel.

ÉTAPES DU PROCESSUS

- Le cadre de levage de sac est fixé au sac en vrac de matériau.

- Un opérateur utilise un chariot élévateur pour soulever le big bag au-dessus du déchargeur.

- Le cadre de levage avec le big bag est ensuite placé sur le cadre de tension latéral.

- Le poids du sac provoque la compression des ressorts du cadre de tension, ce qui permet au poids du sac en vrac de se déposer sur le plateau de support.

- Une fois le sac solidement en place, l'opérateur accède au bec de sortie du sac en vrac via la chambre de dénouement.

- L'opérateur procède ensuite à l'abaissement du bec de sortie, puis engage les barres de fermeture du bec pour empêcher l'écoulement de matière lors du dénouement.

- L'opérateur enroule le bec de sortie et la doublure (le cas échéant) autour du tuyau de descente.

- Ensuite, l'opérateur actionne les deux interrupteurs de sécurité, abaissant la bague de retenue autour du bec de sortie du sac et sur le tuyau de descente.

- Avec l'anneau de retenue entièrement engagé, un anneau gonflable se dilate pour créer un joint sécurisé et étanche à la poussière.

- Enfin, l'opérateur ferme la chambre de dénouement et ouvre les barres de fermeture du bec verseur pour initier le déchargement du matériau du big bag.

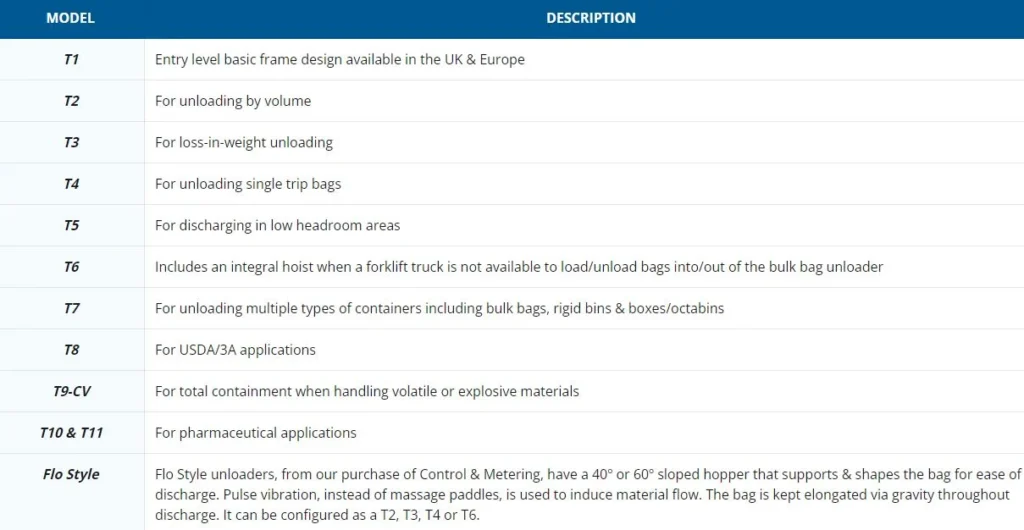

MODÈLES ET SPÉCIFICATIONS

Le déchargeur de big bag T9-CV n'est qu'un des nombreux modèles disponibles dans notre collection, en plus des systèmes de convoyeurs industriels. Notre gamme de modèles est dotée de diverses fonctionnalités qui peuvent être personnalisées pour répondre aux exigences uniques d'applications spécifiques. Nous créons régulièrement des modèles personnalisés pour nos clients afin de répondre à leurs besoins. Vous trouverez ci-dessous un aperçu de nos modèles fondamentaux. Un ingénieur commercial Spiroflow évaluera vos besoins spécifiques pour vous suggérer la configuration la plus adaptée à votre projet.