We are delighted that Premier Foods, the brand leader, has recently purchased from us. They bought two Spiroflow Big Bag Dischargers and four Flexible Screw Conveyors to bring processed products to packing lines at their Histon site. The product in question is SMASH Instant Mashed Potato. As Premier Foods’ 1970s “Martians” advertisement has been voted the best TV ad of all time, SMASH ranks among the UK’s best-known consumer brands.

Premier Foods operates seven production sites in the UK and employs over 3,000 people. Their Histon site has been in existence for over 100 years with a complement of around 350 employees. It is also the home of Hartley’s Jam, Rose’s Marmalade, and Chivers Jelly.

Introduction to Advanced Discharging and Conveying

A shift in SMASH’s production and storage approach necessitated the integration of new Big Bag Dischargers and Flexible Screw Conveyors. Unlike the previous method of moving products through overhead bandes transporteuses from production to packing, the current process involves using 2m3 big bags. These are transported by forklift trucks at a rate of 16 per day, ensuring a streamlined and continuous workflow from production to packing.

Efficient and Secure Discharging Process

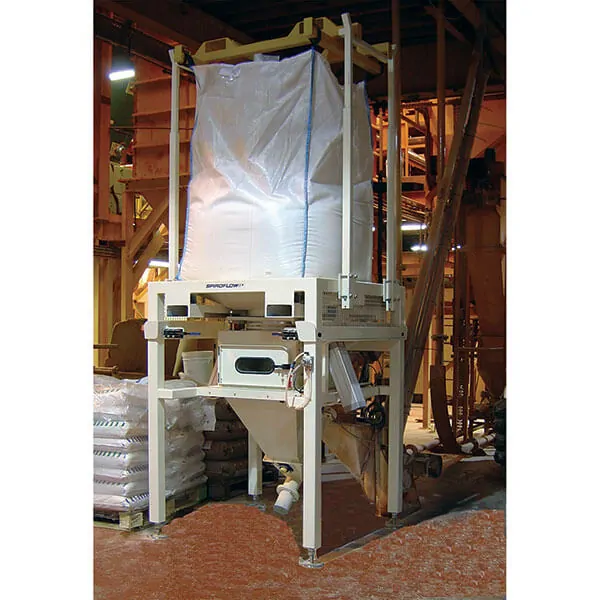

The introduction of Spiroflow Big Bag Dischargers has significantly enhanced the packing hall operations. These dischargers, equipped with Big Bag Lifting/Support Frames, ensure a dust-free transfer of contents.

The unique design featuring an annular flexible membrane creates a dust-tight seal, facilitating a controlled and safe discharge process. The system’s efficiency is further enhanced by pneumatic spout closure bars and a smart mechanism that gradually raises the lightning bags to optimize product discharge.

Seamless Product Distribution With Flexible Conveying Solutions

At the heart of the operation, Spiroflow’s advanced conveying solutions play a pivotal role in streamlining the transfer of materials to the packing lines. These systems are designed with flexibility and precision in mind, ensuring that products are moved efficiently and effectively to their destinations. Here’s how Spiroflow’s Flexible Screw Conveyor enhances the process:

- Utilize two Spiroflow Flexible Screw Conveyors from each discharger to ensure thorough distribution to four packing lines.

- Conveyors are adjustable in length and angle. This allows for a versatile setup.

- They incorporate level probes for precise control of flow and volume, maintaining consistent production quality.

Our Commitment is to Quality and Efficiency

The decision to partner with Spiroflow was influenced by the successful use of their equipment in handling sugar. Also, the positive outcomes from tests conducted to tailor the system for SMASH cemented this deal.

This customization, coupled with in-house designed control systems, underscores Spiroflow’s dedication to providing optimal conveyor technologies for industrial applications. The result is a system that not only meets Premier Foods’ expectations but also delivers significant improvements in product quality, labor, and utility savings. All of this underlines the value of investing in top-tier conveyor manufacturers and technologies.

Enhance Your Production Efficiency With Spiroflow Conveyor Solutions

If you want to boost your production as well, feel free to reach out to Spiroflow. Our team is ready to provide you with customized solutions tailored to meet your needs, leveraging our advanced conveying and discharging technologies. Whether you’re looking to enhance efficiency, improve product quality, or reduce costs, our conveyor systems manufacturers have the expertise to make it happen. Don’t let your production challenges hold you back. Contacter Spiroflow today and take the first step towards optimizing your material handling process.