Base Model Bulk Bag Fillers

System OVerview

In addition to Spiroflow’s advanced conveyor technologies, our basic model bulk bag fillers feature a simple frame design ideal for low-volume filling. These fillers are robust, offering, offering the flexibility to be constructed from STEEL-IT polyurethane-coated carbon/mild steel or stainless steel, based on the specific environmental demands.

You can easily unload bulk bags using a forklift or pallet truck. Plus, our inflatable neck seal keeps dust from escaping, and the filling head has a dust filter to prevent materials from being carried away in the air. For dust-free granular materials like certain plastics, filtration isn’t necessary.

Explore the Key Features of Spiroflow's Base Model Bulk Bag Fillers

- Total Containment

- Low Cost Volumetric Filling

- Dust-free

- Pallet Truck Bag Removal

- Forklift Bag Removal

How Do They Work and What Are the Benefits?

Spiroflow’s base model bulk bag fillers are of particular interest to companies using bulk bags to store and/or transfer raw materials, semi-processed or finished products. This economical bulk bag-filling choice should be considered when:

- Conveyed material is pre-weighed for bags being filled,

- Low number of bags filled per day,

- Product naturally settles and doesn’t require compaction, or have minimal filling needs,

- Safety is a concern with unstable bags containing aerated materials that can topple.

The inflatable neck seal prevents dust from escaping during bag filling. The fill nozzle contains a dust vent that can be hooked to a central dust collection system, or covered with a filter sock.

Requirements for Choosing the Right Bulk Bag Filler

Before choosing a specific bulk bag filler, it’s essential to take into account several pivotal factors. This process helps our design engineers determine the best filler for the application.

How Do We Handle the Bulk Bag?

Bulk bags can be handled using forklifts or pallet trucks.

What Bag Style and Size Do We Use?

At this point, it’s essential to engage in discussions with both the bag manufacturer and Spiroflow to ascertain the appropriate bag style and dimensions. The objective is to optimize the bag’s capacity, ensuring safe storage and efficient transportation. Spiroflow has witnessed impressive outcomes with Ameriglobe’s Fusion Baffle Bag, a seam-free design that often alleviates the need for a liner.

How Do We Contain Dust?

An inflatable neck seal efficiently encloses the dust during the filling process. All our filling heads feature an inner pathway for the product flow and an outer annular space for dust removal, complete with a dedicated dust extraction port.

Can the Filling System Be Automated?

When utilizing volume-based filling, it’s prudent to explore supplementary choices such as pallet dispensers, automated bag loop release mechanisms, as well as industrial conveyor systems designed for bag take-off and accumulation within an industrial setting. Notably, these features can be incorporated into Spiroflow’s standard bulk bag-filling equipment at a later stage if required.

Will the Equipment Need to Be Grounded?

In situations where there’s a potential for explosions, it’s advisable to consider the use of bags that are either static dissipative or can be grounded. Additionally, it’s prudent to deploy an appropriate static monitoring device.

Can We Use Nitrogen Purging?

The utilization of nitrogen purging presents an alternative method. Conventionally, when filling bags, air is introduced to inflate them before the filling process begins. However, opting for nitrogen instead can effectively extend the shelf life of the product.

Do We Need a Bag Liner?

A lined bag is recommended if the product is very fine, you probably will, to prevent leakage or moisture ingress. However, various alternatives can be used, such as coated bags or special bag seams. The liner must be inflated correctly to avoid creasing and subsequent discharge problems.

Is Your Product Highly Aerated? Do You Have Problems Producing Upright, Stable Bags?

Vibration at the base of the unit deaerates and compacts the product to optimize the bag volume and form a safe and stable load. The CTE bulk bag filler uses our patented Cone Table densification for highly aerated powders.

Is Automatic Loop Release and Height Adjustment Available?

Generally, this is the case. Vibrations applied at the unit’s base serve to deaerate and consolidate the product, ensuring optimal bag capacity and creating a secure and steady load. The CTE bulk bag filler employs our patented Cone Table densification technique, which is particularly effective for powders with high aeration levels.

Can the Equipment Be Adapted to Fill Other Containers?

Yes. Spiroflow is one of the conveyor systems manufacturers that supply a range of options for filling rigid bins, drums, and boxes/octabins.

Check Out Our Application Options

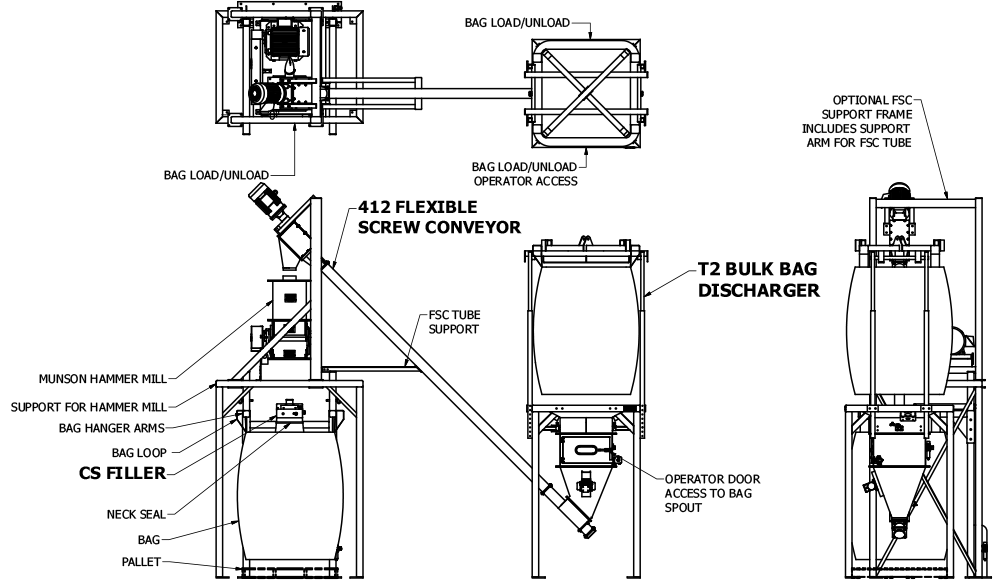

Uncover the versatility of our conveyor solutions, including the flexibility of a flexible screw conveyor. As we showcase just one of the numerous processing solutions available through our CS bulk bag fillers, explore how these innovative systems can streamline your material handling and bag-filling needs. Here is an example of one of the many processing solutions we provide utilizing CS bulk bag fillers.

Models and Specifications of Our Base Model Bulk Bag Fillers

FILL RATE & BAG CAPACITY

- Up to 20 bulk bags/hour

- Bag capacity – 4,400 lb/2,000kg

STANDARD MATERIALS OF CONSTRUCTION

- Carbon/mild steel or stainless steel materials of construction

FRAME STYLE & STANDARD COMPONENTS

- 2 Post Design – Two vertical tubes welded to the steel base plate

- Steel base plate

- Vertically adjustable horizontal loop support arms

- Filling nozzle and frame

- Sliding sections with locking pins for positive location

LOAD CELLS

- None

TYPICAL DIMENSIONS

- Height: 94”/239cm

- Width: 48”/122cm

- Depth: 48”/122cm with average pallet

PNEUMATIC REQUIREMENTS

- 80 psi/5.5 bar @ 30 CFM (850 l/cycle) for inflatable neck seal & bag inflation

DUST CONTROL/ AIR DISPLACEMENT

The filling nozzle incorporates a unique design featuring an inner open-ended cylinder paired with a second concentric cylinder, which is sealed at one end by an annulus. Within this configuration, the product flows through the central cylinder, entering the bulk bag, while any displaced air and dust are channeled through the outer chamber. From there, they are directed through a dust sock to connect to the customer’s dust collection system.

To keep the bags in place, an external spring clamp is used to secure them to the nozzle.