T1 Simple Frame Bulk Bag Unloader

System OVerview

Spiroflow T1 Simple Frame Bulk Bag Unloader is designed as an optimal solution for low-volume discharging of free-flowing products. This equipment, available in the UK, Europe, and Asia, not only makes the handling of bulk bags effortless but also ensures a clean and dust-free operation. Let’s check out how you can streamline your operations and elevate your industry standards with our top-notch equipment.

Overview of Our T1 Simple Frame Bulk Bag Unloader

The T1 Bulk Bag Unloader, offered in the UK, Europe, and Asia, is an economical solution for a low-volume discharging of free-flowing products.. This equipment offers a reliable solution for businesses with low-volume product unloading needs. Explore the features, benefits, and components of the T1 Simple Frame Bulk Bag Unloader to discover how it can elevate your operations to new heights.

Key Features of T1 Simple Frame Bulk Bag Unloader

- Small Footprint

- Low Maintenance

- Affordable

How Does Spiroflow T1 Simple Frame Bulk Bag Unloader Work?

The operation of the Spiroflow T1 Simple Frame Bulk Bag Unloader is straightforward. A lifting frame is attached to the bulk bag and lifted with a forklift into a secure bag hanging frame, with spring-loaded side support arms, if required, ensuring minimal residue and maintaining bag tension throughout the discharge process.

This hopper can be connected to various conveyor technologies, such as a flexible screw conveyor, to create an integrated and efficient bag unloading and transfer system. This adaptable system can accommodate a wide range of bulk bag types and sizes, provided they are clearly defined.

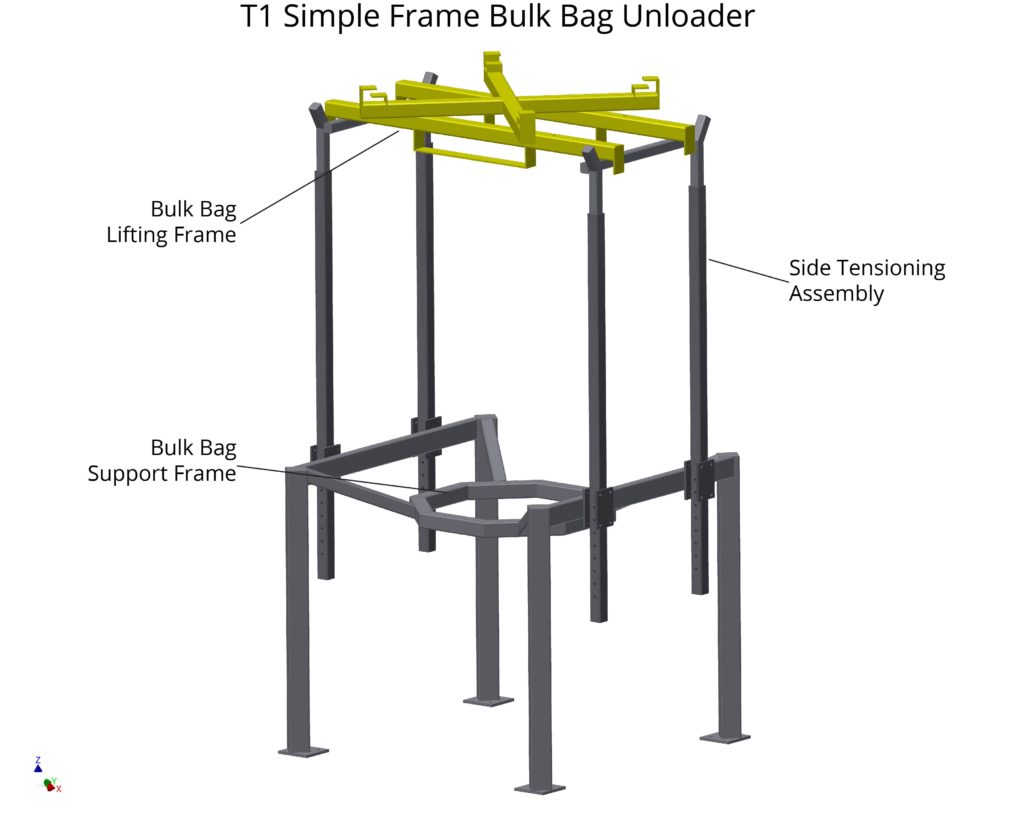

Components of the T1 Simple Frame Bulk Bag Unloader

At the core of the T1 Simple Frame Bulk Bag Unloader are key components engineered for efficiency and durability. These components include the heavy duty bulk bag support frame which works seamlessly with material conveyance equipment. These elements ensure seamless operation, reliability, and longevity in a wide range of industrial applications.

Bulk Bag Support Frame

A substantial four-legged box section bag support frame, incorporates a bag support ring through which the base spout of the bag is located. The unit is manufactured in a carbon/mild steel box section finished in two-pack epoxy paint or 304 stainless steel.

Hygienic Bulk Bag Neck Clamp Ring

The manually operated bag clamp prevents spillage and dust from escaping during discharge. The over-center clamps raise and lower the upper portion, which contains the seal closing outside the spout. This component is mostly constructed of 304 stainless steel except for the clamps, which have a cast iron body and plated moving parts.

FAQ

The T1 Unloader is designed for low-volume discharging of free-flowing products, making it an ideal choice for various materials, including grains, powders, pellets, and other bulk goods.

Yes, the equipment is designed with ease of cleaning in mind. Minimal moving parts allows for low maintenance.

Yes, the system is highly adaptable and can accommodate a wide range of bulk bag sizes and types, provided they are clearly defined. This flexibility is a trademark of our equipment, and ability to accomplish any demands.

The bulk bag support frame is available in carbon/mild steel with an epoxy paint finish or 304 stainless steel. The hygienic bag neck clamp ring is primarily constructed from 304 stainless steel, with a cast iron body and plated moving parts for durability.

The T1 Unloader can be directly connected to various industrial conveyor systems, creating a complete bag unloading and transfer system. Additional equipment may be required based on your specific production setup and requirements.