Aero Mechanical Conveyors

System OVerview

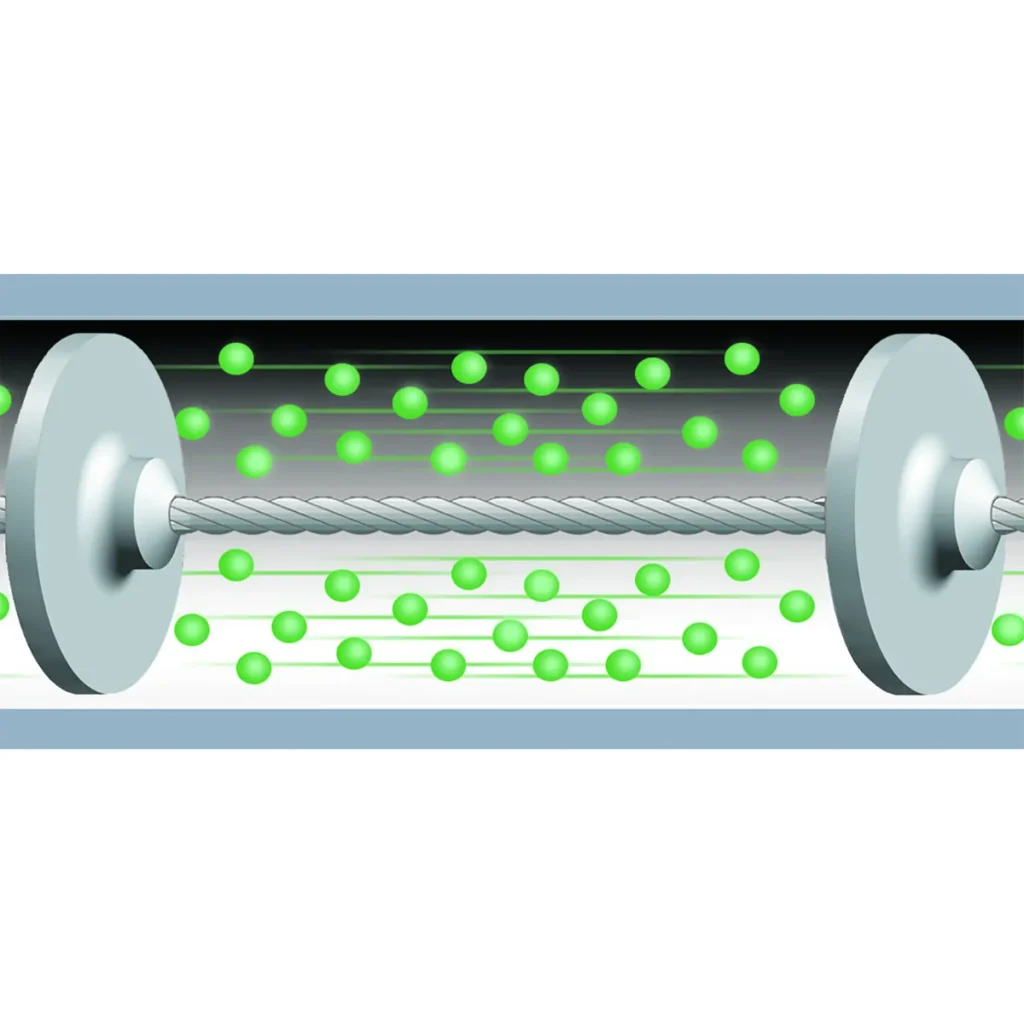

Spiroflow’s Aeroflow aero mechanical conveyors feature a high-speed cable assembly with evenly spaced discs made of polyurethane housed in a tubular structure. This innovative design creates a consistent airstream that fluidizes and transports materials efficiently.

Aeromechanical conveyors offer high speed mechanical material conveyance with complete transfer of all material. Ideal for loss in weight applications where an entire batch must be accurately transferred.

Aeromechanical conveyors require a metered infeed of material while running. Preventing conveyor binding or material collection in the inlet housing.

Benefits

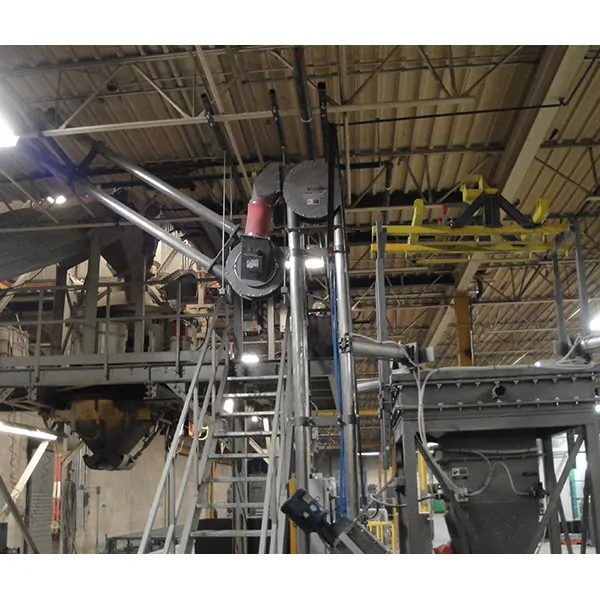

Spiroflow has established a global presence with our aero mechanical conveyors. These systems are renowned for their reliable operation in various industries worldwide.

Aeromechanical conveyors operate within a completely enclosed tubular system, making them ideal for the transfer of even the smallest grain materials, completely dust-free. This feature positions us as a leading choice for businesses seeking efficient and clean conveyance solutions.

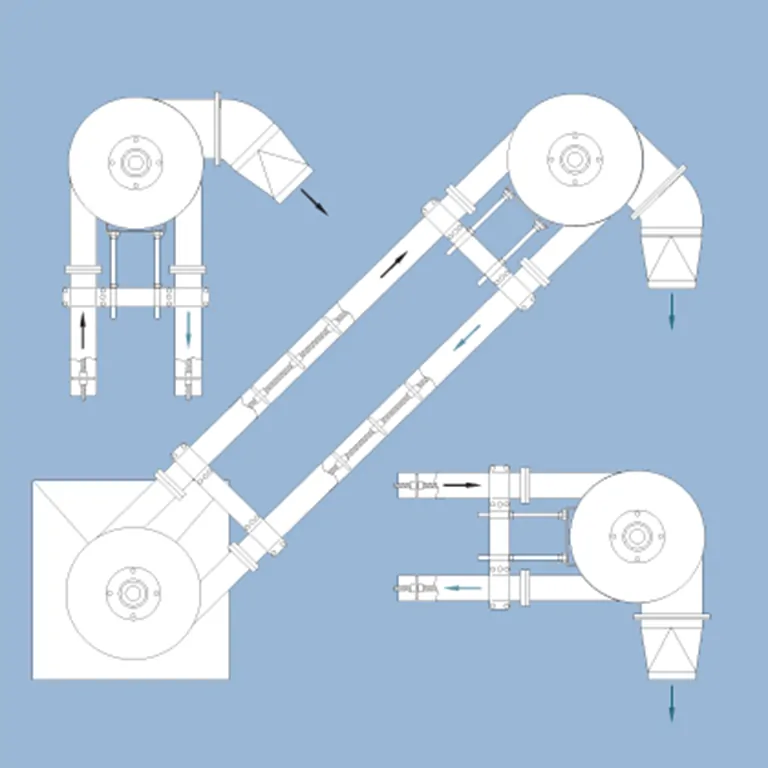

Spiroflow’s aero mechanical conveyors are uniquely versatile, capable of transporting materials at angles ranging from 0° to 90° without any loss in capacity. Also Aeromechanical conveyors can utilize corner housings to allow Z-Configurations.

Our aero mechanical conveyors are designed for minimal maintenance, thanks to their efficient complete transfer capability. For the majority of applications, cleaning isn’t required, making them a practical choice for industrial conveyor systems. To prevent cross-contamination, a simple purging is often enough. For thorough cleaning, they come equipped with safety interlocked hatches for both the tubes and sprocket housings. For more intensive cleaning needs, our conveyors can be equipped with drains and wash gates, allowing for a comprehensive wash with cleaning fluids or water.

As versatile conveyor systems manufacturers, we offer Spiroflow aero mechanical conveyors mounted on wheeled frames, complete with controls and power connections. This mobility allows a single conveyor to serve multiple processes or be moved to a designated wash-down area. Our mobile units can also feature optional height adjustment, perfect for environments with low doorways or varying discharge heights.

Spiroflow’s aero mechanical conveyors are capable of operating at as much as 36 ft³/min (2,160 ft³/hour) or 1 m³/min (61 m³/hr), handling products like flour with ease. They can achieve conveying rates exceeding 160,000 lb/hr (or 72,600 kg/hr), although rates can vary based on the product’s bulk density.

Our conveyors ensure the integrity of mixtures during transport. The controlled rate at which products are fed into the conveyors results in consistent amounts in each pocket between the discs.

Our aero mechanical conveyors are versatile and capable of handling a wide range of materials, from the finest powders to various granules, pellets, flakes, and flocks. They are particularly effective with challenging materials like titanium dioxide, known for its conveyance difficulties.

Unlike other conveyor technologies, our aero mechanical conveyors don’t add extra air for material conveyance, eliminating the need for outlet dust filtration. Untransferred materials are contained within the system until they are eventually ejected, ensuring a clean operation.

When it comes to energy efficiency, our conveyors excel. They are designed for low power consumption, making them one of the most energy-efficient industrial conveyor systems available. This translates into significant energy savings and reduced operational costs.

Our conveyors ensure complete batch transfer from inlet to outlet. It makes them ideal for moving batches (pre-weighed) or smaller bulks of ingredients without loss or contamination.

Flexibility is a key advantage of our system. It can be configured with multiple inlets, allowing a single conveyor to receive material from multiple sources.

HOW IT WORKS

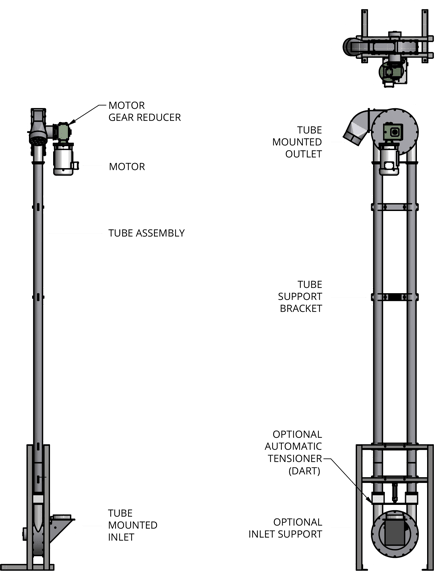

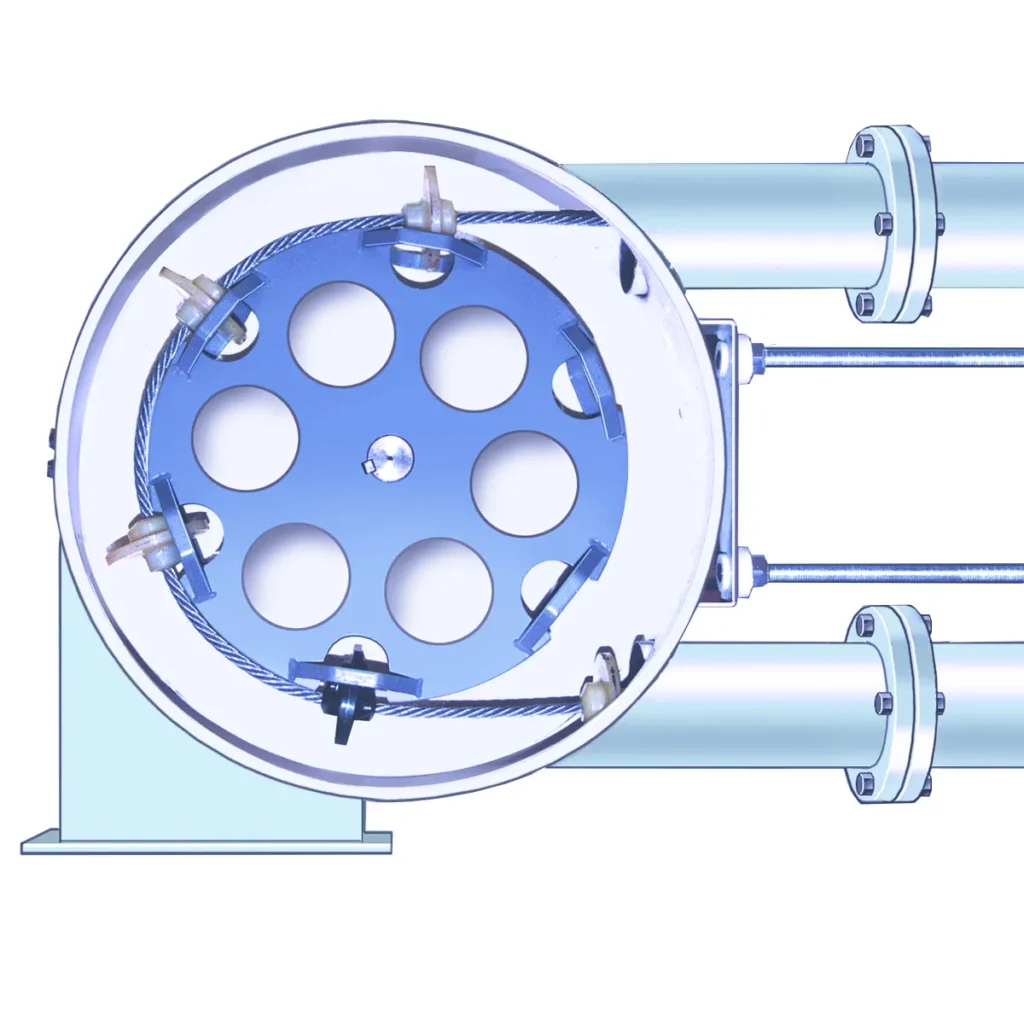

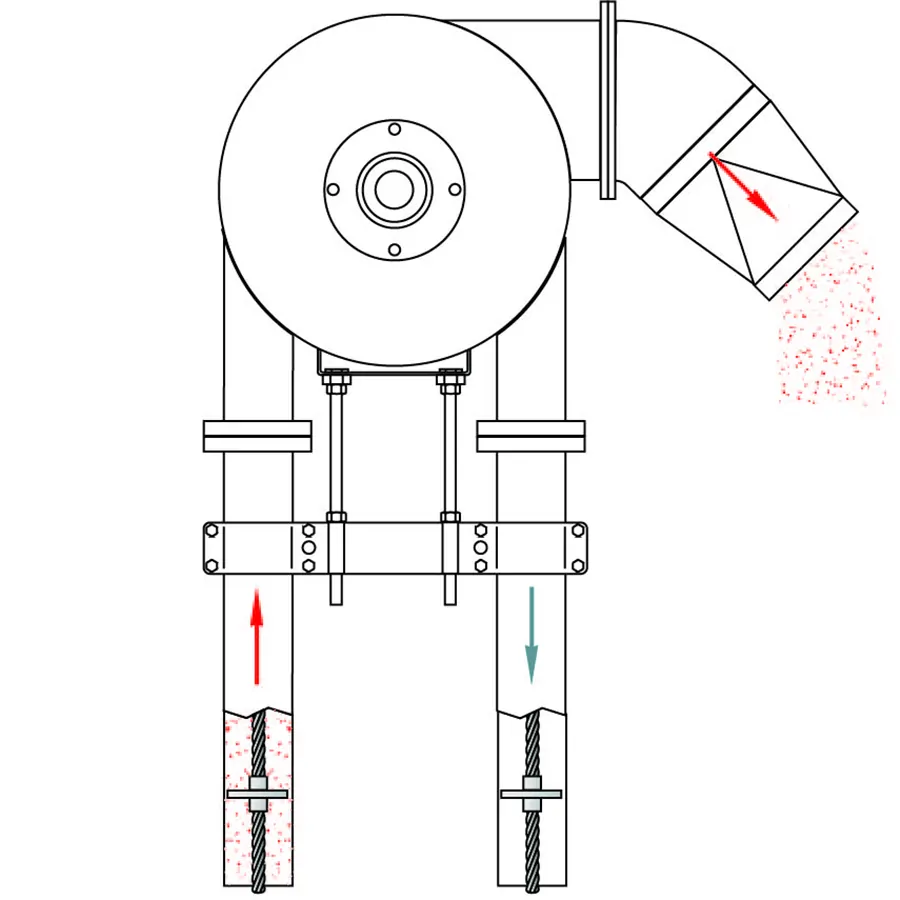

The aero mechanical conveyor features a tube in which a stainless steel cable, outfitted with evenly spaced discs made of polyurethane, is pulled through at a rapid pace. The cable and disc setup is looped around specifically designed sprockets at each conveyor end. One sprocket functions to drive the cable, while the other maintains its tension. Depending on the conveyor’s length and specific plant layout needs, the drive assembly will be placed at either the outlet or inlet.

The cable and disc assembly moves at a high rate of speed to generate and airstream within the conveyance tube. Material is introduced into the airstream, smoothly transporting it to the conveyor’s end, where it’s expelled through centrifugal force. The system is designed for high-capacity conveyance while keeping energy usage low, ensuring complete transfer of material.

APPLICATIONS

Our aero mechanical conveyors have garnered widespread appreciation across various sectors for their reliable and consistent performance. These systems adeptly handle a range of tasks, from the straightforward transfer of food ingredients to the more challenging conveyance of abrasive and corrosive materials found in the chemical industry. The versatility and robustness of Spiroflow aero mechanical conveyors make them suitable for efficiently managing a diverse array of products.

Titanium Dioxide

Our aero mechanical conveyor is adept at handling titanium dioxide, recognized as one of the most effective solutions for transporting this material.

Elevating Material

Aeromechanical conveyors are capable of moving material vertically, or at any angle in between.

Multiple Inlets

With multiple infeed capability the Aeromechanical is capable of conveying material from multiple sources.

Tanker Loading

Handling minerals and ceramics is a demanding task, but Spiroflow’s equipment is robustly designed to withstand these challenging requirements, making it ideal for tanker loading applications.

Feeding Additives

Our aero mechanical conveyors, both inclined and horizontal, are perfect for feeding additives into one of two storage tanks.

Around Corners

Mechanical corners allows Aeromechanical conveyors to make 90 degree changes in direction.

Mobile Conveyor

Our mobile aero mechanical conveyors are extensively used in various settings, both inside and outside of factory environments, for their versatility and efficiency.

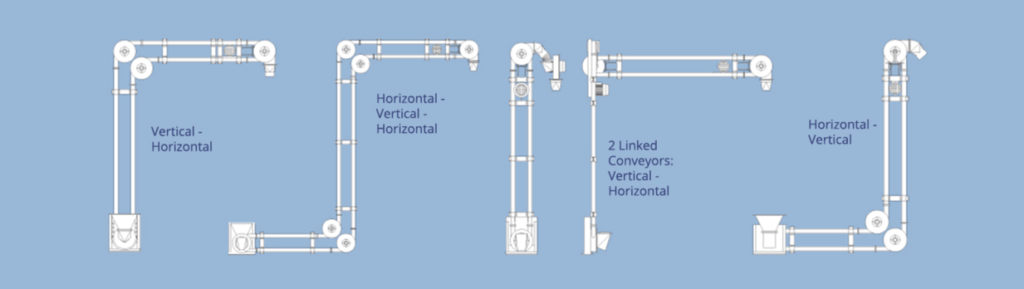

CONFIGURATIONS

Some of Spiroflow’s basic aero mechanical conveyor configurations are shown here.

Custom layouts can be designed to meet specific requirements.

MODELS & SPECIFICATIONS

Model

PC3

PC4

PC5

Tube Size (OD)

3" / 75 mm

4" / 100 mm

5" / 125 mm

Maximum Conveyor Length

Up to 65' / 20 m

Up to 82' / 25 m

Up to 82' / 25 m

Maximum Cable Speed

750 ft/min (230m/min)

1000 ft/min (300m/min)

1200 ft/min (365m/min)

Typical Capacity Up To

9 ft3/min

(0.25 m3/min)

18 ft3/min

(0.5 m3/min)

36 ft3/min

(1 m3/min)

Standard Construction & Components:

- Tubes: 304 stainless steel

- Cable: 304 Stainless Steel

- Discs: Polyurethane

- Manual Inlet Baffle

- Manual Cable Tensioner

Electrical Requirements:

- 2 – 7.5 HP / 1.5 – 4 KW Motor

COMPRESSED AIR REQUIREMENTS

- 60 – 80 psi

INLETS, OUTLETS & FEEDING

- Multiple inlets & outlets

- Must be meter fed

- Inlets can be fitted with baffles, lids, hoppers, agitators, etc.

- Custom designs available

COMPONENTS & OPTIONS