Bulk Bag Conditioners

System OVerview

Does your material arrive compacted & difficult to empty from bulk bags? Bulk bag conditioners can resolve these compaction issues & enable easy discharging from your bulk bag unloader.

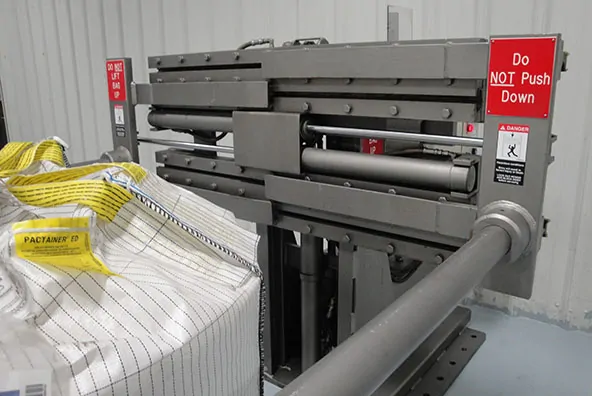

Spiroflow’s bulk bag conditioner easily and effectively breaks up solid ingredient contained within bulk bags. Depending on your material it may require only two or three ‘squeezes’ to do the job. Simply move the bulk bag between the horizontal poles (with a forklift, hoist or automatically using motorized conveyors) and actuate the hydraulic drive mechanism to quickly and efficiently break up the solid ingredient. Due to its small footprint, our bag conditioner can be located conveniently next to the area where bulk bags are emptied or near incoming storage minimizing the use of valuable floor space.

The bag conditioner can be configured to meet your operational needs with a fixed or movable mast and can be manually operated or integrated into an automated system. Additionally, it can be integrated within the support framework of a bulk bag unloader.

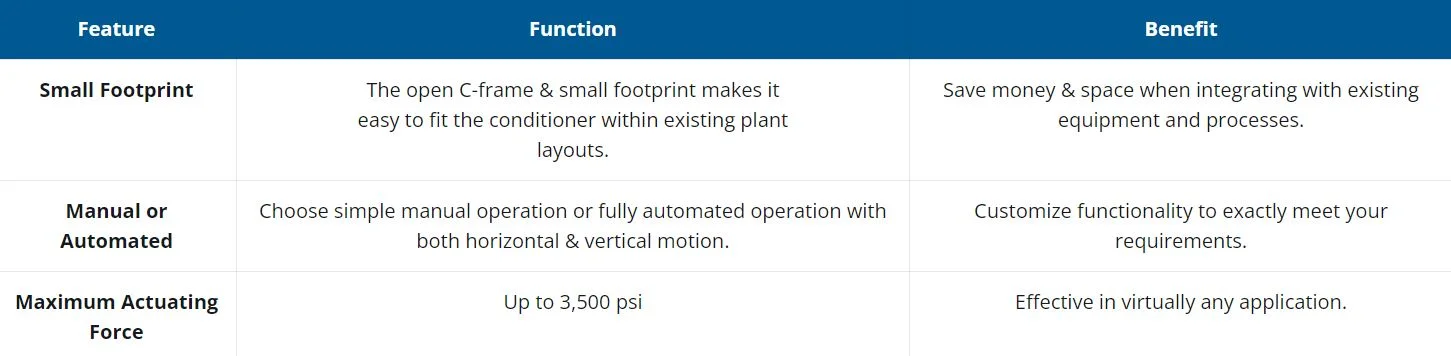

Features

- Squeezes the Bulk Bag Easily

- Small Footprint

- Moveable Automated Mast

- Manual or Automated Operation

- Integration into a Bulk Bag Unloader

HOW IT WORKS & BENEFITS

Flexible screw conveyors, or auger conveyors, can be utilized in a number of different configurations. Here is a sampling of configurations we see regularly:

Place the bulk bag between the poles.

Use the controls to move the poles.

Condition the top section of the bulk bag.

Condition the middle section of the bulk bag.

Condition the bottom section of the bulk bag.

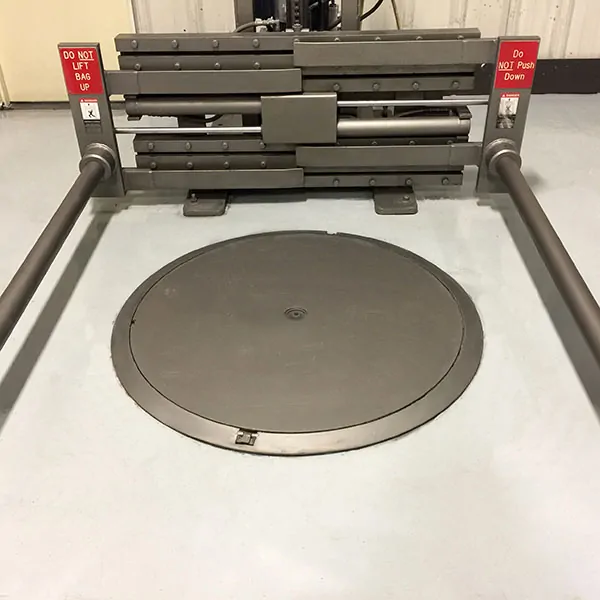

Turn the bag on the turntable as needed.

MODELS & SPECIFICATIONS

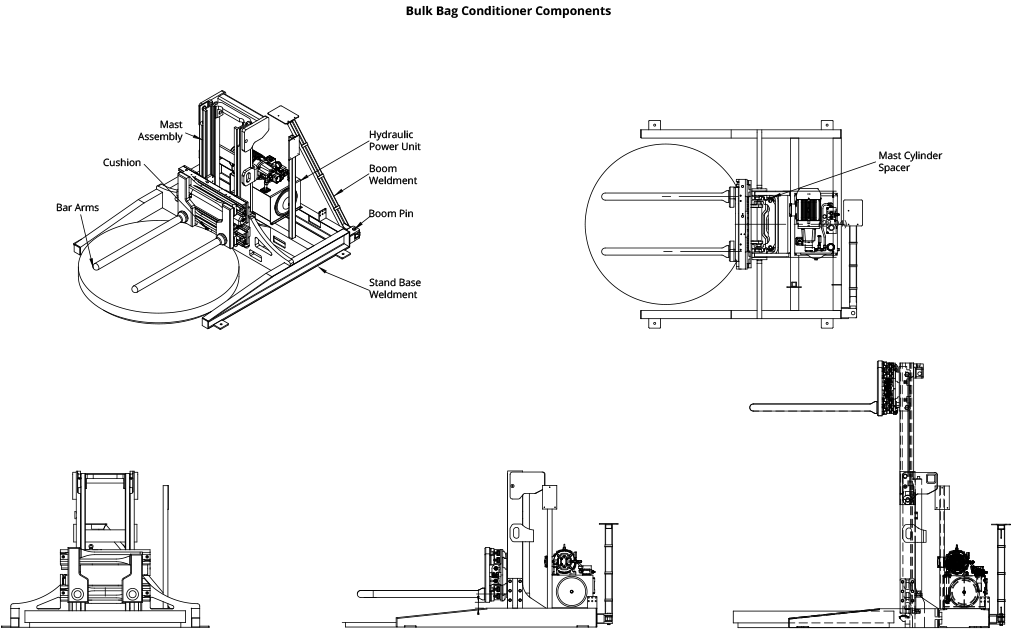

HYDRAULIC BULK BAG CONDITIONER WITH FIXED CARRIAGE

General Arrangement:

The standard fixed mast arrangement maintains poles at a fixed elevation. External equipment is required for bulk bag positioning.

Fixed Carriage Manual Operation:

The bulk bag is positioned between the pole arms.

The pole arms are activated by the operator using the hand lever controls to squeeze the bag.

A forklift or hoist is required to raise & lower the bag to allow the squeezing operation at various locations along the height of the bag to ensure hard set ingredients are broken up within the bag.

Material of Construction:

The Bulk Bag Conditioner is constructed of carbon/mild steel components & a carbon/mild steel squeezing mechanism.

Standard Finish:- Bag conditioner mechanism has a baked-on powder coated finish.

- The support structure is gray enamel painted.

Bag Conditioner Includes:- Conditioning Mechanism: 38” / 965mm W

- Pole Arms: 3” / 76mm Ø, 54” / 1,372mm L

- Inside Pole Clearance: 21 – 63” / 533 – 1600mm

Fixed Mast:- Mast Dimensions: 50” L x 56” W x 78” H / 1,270mm L x 1,422mm W x 1,981mm H

- Pole Height: 61” / 1,549mm H as standard, custom pole heights available

- Clamping Force: Up to 3,500 psi

- Hydraulic Power Pack consists of:

- 10 HP (.75KW) TEFC Motor

Hydraulic Pump with a 20 US Gallon Reservoir - Level & Temperature Gauge

- Filler/Filter/Breather

- Return Filter

- Adjustable Valve

- Hydraulic Hoses & Connections

- Hand Lever Controls & Motor Starter Panel

- 10 HP (.75KW) TEFC Motor

Customer to supply their own fused power assembly.

HYDRAULIC BULK BAG CONDITIONER WITH MOVABLE MAST

Manual Movable Mast Operation:

The bulk bag remains stationary while the poles arms are moved up & down along the bag height to allow squeezing at various locations.

No external equipment is required for bag positioning.

Material of Construction:

Constructed of carbon/mild steel components and a carbon/mild steel conditioning mechanism

Standard Finish:

- Bag conditioner mechanism has a baked-on powder coated finish.

- The support structure and movable mast is enamel painted.

Bag Conditioner Includes:

- Conditioning Mechanism: 38” / 965mm W

- Pole Arms: 3” / 76mm Ø, 54” / 1372mm L

- Inside Pole Clearance: 21 – 63” / 533 – 1600mm

Movable Mast:

- Mast Dimensions: 50” L x 56” W x 78” H / 1,270mm L x 1,422mm W x 1,981mm H

- Mast Lifting Height: 5 – 66” / 127 – 1,676mm from ground to bottom of carriage

- Clamping Force: Up to 3,500 psi

- Hydraulic Power Pack consists of:

- 10 HP (.75KW) TEFC Motor

- Hydraulic Pump with a 20-gallon/76-liter Reservoir

- Level & Temperature Gauge

- Filler/Filter/Breather

- Return Filter

- Adjustable Valve

- Hydraulic Hoses & Connections

- Hand Lever Controls & Motor Starter Panel

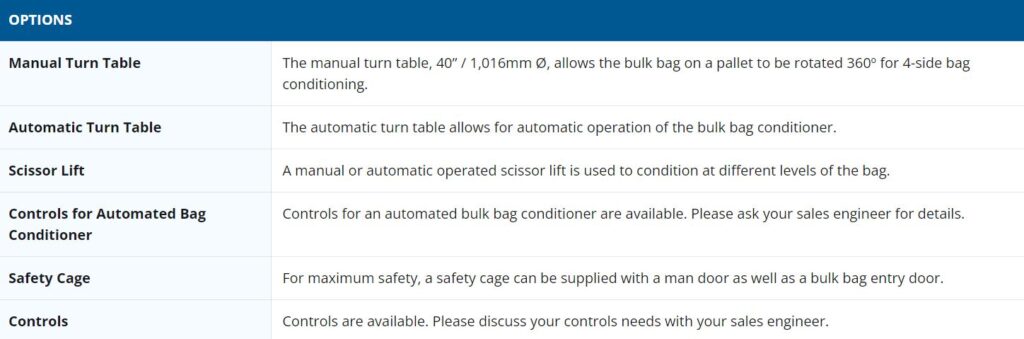

CONFIGURATIONS

Fixed Mast, Manual Operation

Either a forklift or hoist is required to move the bulk bag into the Conditioner. The bag is then raised or lowered between each actuation to ensure complete breakup of the solid ingredient. The hydraulic drive system is controlled with the included manual lever switches.

Moveable Mast, Manual Operation

In this configuration, the poles move up and down along the mast. The bag remains stationary within the Conditioner and the poles move to provide full coverage.

Moveable Mast, Automated

The Bulk Bag Conditioner can be automated such that a bulk bag is placed on a motorized roller conveyor, automatically feed into the Conditioner, conditioned and automatically removed from the Conditioner for pickup by a forklift or hoist. The automated sequence can be initiated by a forklift operator without having to leave the truck.