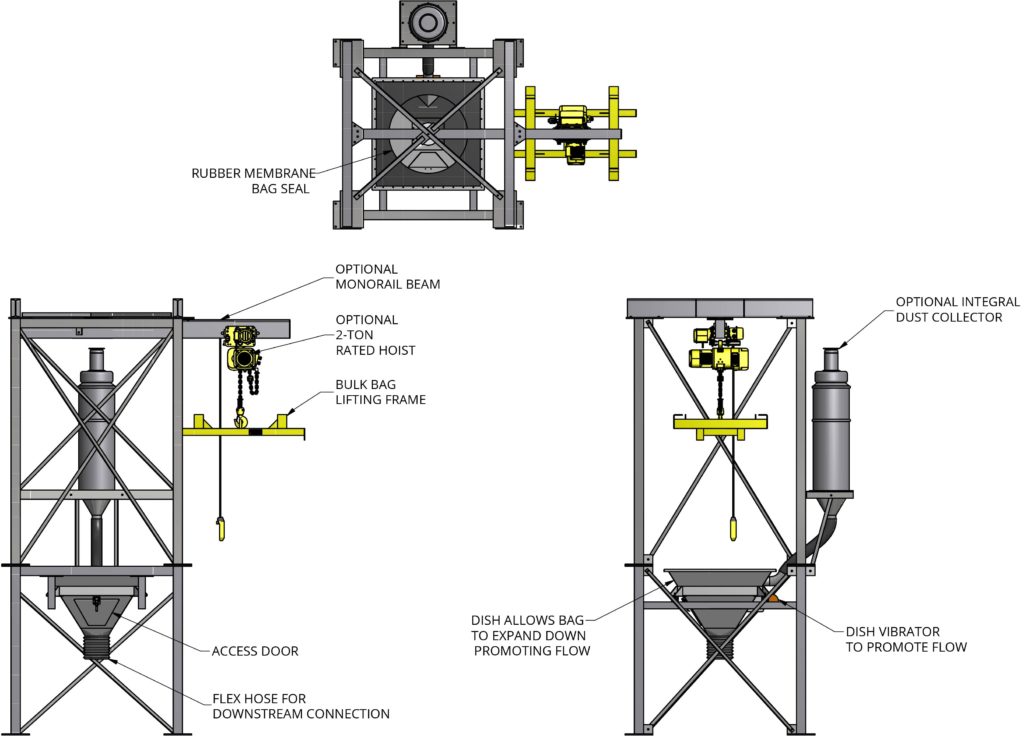

Flo Series Bulk Bag Unloader

System OVerview

Our Flo Series Bulk Bag Unloaders are a design approach from our Control & Metering acquisition. The Flo 40, Flo 60 & Iso Flo designs feature a sloped hopper with pulse vibration.

Flo style designs can be combined with the functionality of our T2 (unloading by volume), T3 (loss-in-weight), T4 (single trip bags) & T6 (integral hoist) unloaders to meet your most exacting application needs.

Features

- The Flo 40 is designed with a 40° sloped hopper for free-flowing pellets, granules, flakes & some powders

- The Flo 60 is designed with a 60° sloped hopper for poor flowing ingredients & high-level dust containment

- Iso Flo has a sloped hopper and is designed for total dust containment

FLO 40

The Flo 40 bulk bag unloader easily and inexpensively empties a wide range of ingredients from any bulk bag. It is suitable for use with easy to moderate flowing ingredients such as pellets, granules, flakes and some powders. Lined or unlined bags with outlet spouts and lined bags with porthole outlets can be emptied. The combination of the Flo 40’s 40° sloped hopper, that converts the cubic shape of a bulk bag into a conical/silo shape, and pulsed vibration is effective in completely emptying ingredient from a bulk bag.

The Flo 40 bulk bag unloader provides a simple and cost-effective solution to emptying bulk bags.

• Easy to moderate flowing pellets, granules, flakes

and some powders

• Lined or unlined with outlet spout

• Lined with porthole in outer bag

• Low investment

• Ingredient easy to moderate flowing

FLO 60

The Flo 60 bulk bag unloader empties difficult flowing ingredients from bulk bags and provides a very high level of dust containment. It is suitable for poor flowing and dusty ingredients that require maximum flow inducement to completely empty bulk bags. Lined or unlined bulk bags with outlet spouts, porthole outlets or plain bottoms can be emptied. The combination of a steeply sloped hopper, that converts the cubic shape of a bulk bag into a conical/silo shape, and pulsed vibration is extremely effective in completely emptying any ingredient from a bulk bag.

Attaching dust collection to the Flo 60’s two dust vents creates a negative pressure area within its hopper. The gum rubber (or nitrile) dust membrane seals with the sides of the bulk bag. These two features mean that the Flo 60 provides excellent dust containment without having to use an outlet clamping device.

• All ingredients, including poor flowing ones

• Granules, pellets, powders, and fibers

• Lined or unlined, with outlet spout

• Unlined, with plain bottom

• Lined, with porthole in outer bag

• Difficult flowing or compacted ingredients

• Dusty ingredient

• Any bulk bag configuration

ISO FLO

The Iso Flo bulk bag unloader provides total dust containment for unloading any ingredient from bulk bags. Dusting problems are often associated with emptying bulk bags. Dust can be generated at the onset of ingredient flow, during discharge and while the bag is being removed from the bulk bag discharger.

Iso Flo bulk bag unloaders feature the patented Flo Super Clean liner and outlet spout clamping system enclosed in an isolation chamber. The clamp system seals the bag outlet. The isolation chamber draws away dust that may be created as the bag is rigged or removed. This combination of technologies provides total containment of airborne particles at each stage of the bulk bag unloading process.

Of course, just like the Flo 40 and Flo 60 dischargers, the Iso Flo features a sloped hopper to safely hold and shape the bulk bag to promote flow. Pulsed vibration ensures that ANY ingredient will be easily discharged. The Iso Flo comes with either a 40 or 60 degree sloped hopper depending on how much flow inducement is required to maintain a flood feed condition at the bag outlet.

COMPONENTS