T6 Bulk Bag Unloader with Hoist

System OVerview

The T6 Bulk Bag Unloader stands as a comprehensive, self-sufficient station designed for the dust-free and regulated emptying of bulk bags, complete with an inbuilt bag lifter. Featuring an integrated “I” beam and hoist, the T6 facilitates effortless bag lifting and loading into the station.

Its connection to a sealed conveyor system ensures products are smoothly transitioned to processing equipment. It allows for the convenient positioning and storage of bulk bags using a pallet truck, eliminating the dependency on forklifts while also boasting complete dust management capabilities.

The T6 Bulk Bag Unloader offers extensive customization, including loss-in-weight controls, an extended gantry for multiple bags, a bag dump door, sanitary clamps, liner removal tools, and bag massagers for optimal material flow. Custom designs are available for specific needs.

Features of T6 Bulk Bag Unloader With Hoist

Cutting-edge conveyor technologies such as the T6 Bulk Bag Unloader With Hoist contribute to a seamless, efficient, and safe material handling process. Let’s go over the innovative design elements that set this system apart:

- Space-saving integral bag hoist with a runway beam

- Integral conveyor or feeder

- No forklift truck is required

- Dispenses contents by volume or weight

- Quiet operation

- Full dust control

HOW IT WORKS & BENEFITS

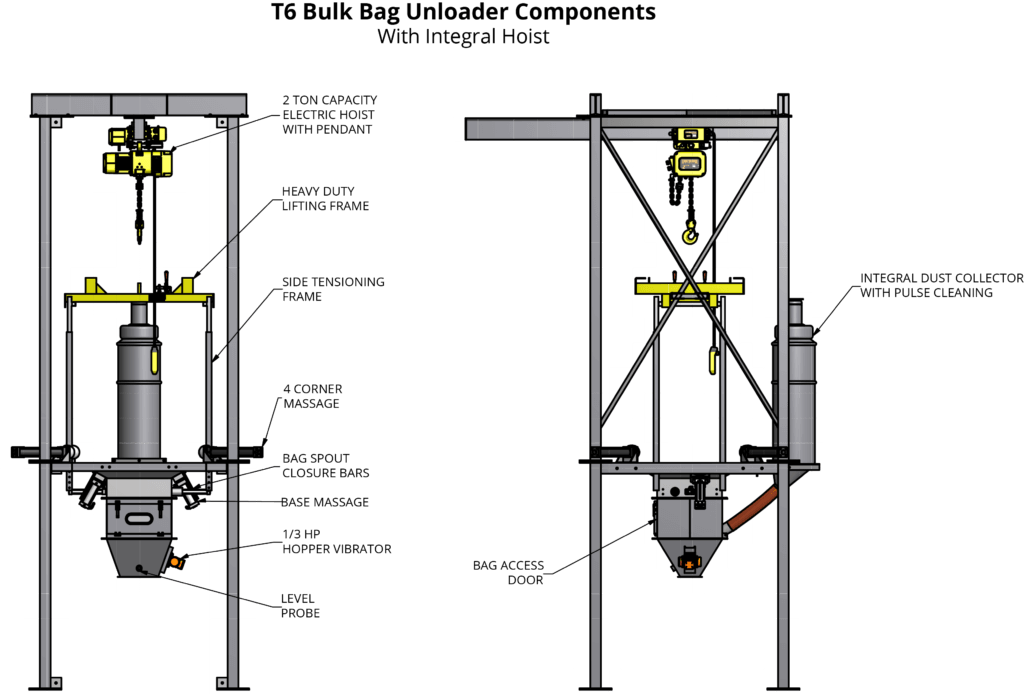

The T6 Integral Hoist Bulk Bag Unloader is the go-to solution for transferring bulk bags to and from its structure without relying on a forklift. Constructed from robust square tubing and featuring cross members, an upper structure, and an integrated “I” beam supporting a 2-ton electric hoist and trolley, this unloader ensures the bulk bag is efficiently lifted onto the support dish.

This arrangement not only secures the bag in place for a dust-free environment but also reinforces the system’s durability with its heavy-duty 4 in./100 mm square steel tube frame, seamlessly welded to the support dish for added strength. Designed with adaptability in mind, the T6 Bulk Bag Unloader offers a variety of design modifications, enhancing its versatility and ease of operation. Furthermore, the output chute is specifically tailored to meet the requirements of each unique application.

Step 1: Attach the bulk bag to the Bag Lifting Frame for secure handling.

Step 2: Use the built-in hoist and trolley system to raise the bulk bag to its designated position.

Step 3: Access the bag's lower spout safely and freely with the Support Dish that securely holds the bag's weight.

Step 4: Proceed with opening the access door and untying the bag spout.

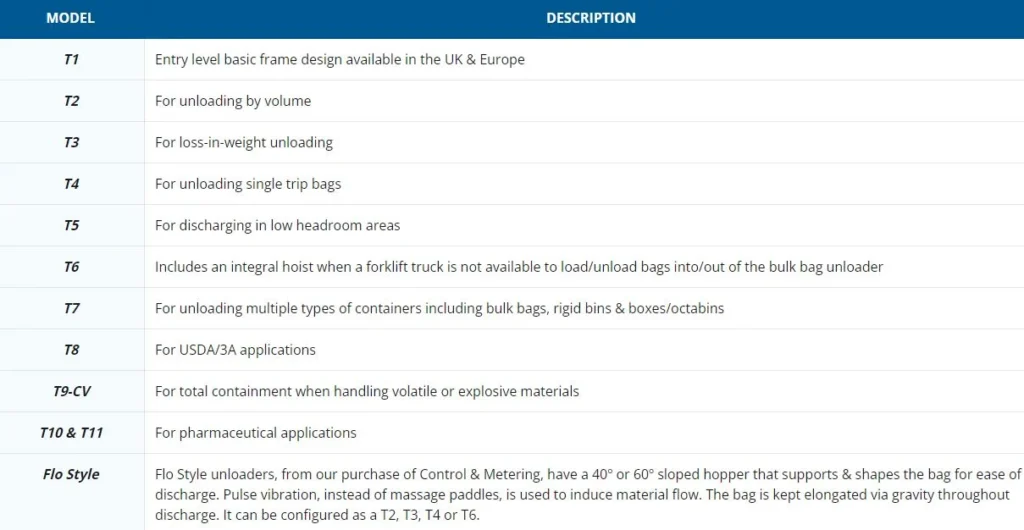

MODELS & SPECIFICATIONS

Our T6 Bulk Bag Unloader, equipped with an integrated hoist for inherent lifting capabilities, represents just one of the many models we provide. We often combine features from different models to meet the precise requirements of specific applications. Moreover, custom designs are a regular part of our service offering. Below is an overview of our standard models. A Spiroflow Sales Engineer will assess your specific needs to suggest the most suitable setup for your operation.

SPECIFICATIONS

The T6 Integral Hoist Bulk Bag Unloader facilitates the forklift-free loading and unloading of bulk bags. It features a sturdy frame with an integrated “I” beam and a 2-ton electric hoist, ensuring precise placement of bags onto a dust-sealing support dish. The device’s heavy-duty construction and customizable options, including a tailored discharge chute, offer versatility and ease of operation for various applications.

STANDARD MATERIALS OF CONSTRUCTION

- Carbon/mild steel is standard,

- Optional 304 or 316 stainless steel is available,

- NOTE: The runway & carrier beams are of carbon/mild steel.

PNEUMATIC REQUIREMENTS

- Side Massage – 80 PSI (5.5 Bar) at 2 CFM (56.6 L)/Cycle,

- Bottom/Dish Massage – 80 PSI (5.5 Bar) at 1 CFM (28 L)/Cycle,

- Corner Massage – 80 PSI (5.5 Bar) at 4 CFM (113.3 L)/Cycle,

- Chute/Hopper Vibrator – 80 PSI (5.5 Bar) at 3 CFM (85 L)/Cycle,

- Spout Closure Bars – 80 PSI (5.5 Bar) at 1 CFM (28 L)/Cycle,

ELECTRICAL REQUIREMENTS

- Optional Chute/Hopper Vibrator – 0.13 hp (.1 kW),

- Optional NEMA 4/ATEX Panel with ON/OFF,

- Optional Hopper Agitator – 0.33 hp (.25 kW),

- Optional Dust Collector – 1.5 hp (1.1 kW),

- Switch for Vibrator or Agitator – 0.33 hp (.25 kW),

- Optional Level Probe – 24V DC.

DUST CONTROL/AIR DISPLACEMENT

- Dust Extraction Port

Optional Integrated - Dust Collector: NEMA 4, TEFC (Stainless Steel Only)

- Optional Integrated Dust Collector: XP (Stainless Steel Only)

- Optional Free-Standing Dust Collector: NEMA 4, TEFC (Stainless Steel Only)