About Spiroflow

History And Who We Are

Empowering Industries, Raising Productivity

Spiroflow stands at the forefront of powder handling and dry solids processing and is making significant strides in control systems integration. Over our 45-year journey, our team of design engineers and process automation experts has consistently delivered the safest, most efficient, innovative, and reliable process solutions, setting industry standards.

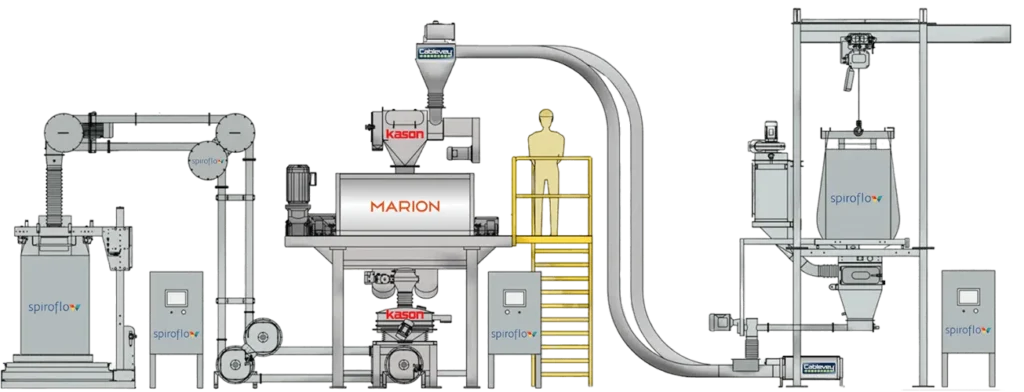

While we pioneered the flexible screw conveyor, Spiroflow has evolved significantly over the years, expanding our product range and service offerings. Our commitment lies in providing engineered solutions tailored to overcome your unique handling and processing challenges, from single conveyors to complete powder handling systems with integrated controls.

Discover the unparalleled variety in mechanical conveyor technologies for dry bulk solids and ingredients – from flexible screw conveyors and Aeroflow® aero mechanical to Cablevey® cable drag and Dynaflow® chain drag conveyors. Our engineers objectively evaluate all your needs to ensure you receive the ideal conveyor belt system for your application.

Explore our extensive Spirofil® range, including bulk bag fillers, bulk bag conditioners, control systems, bulk bag unloaders, and custom-designed hoppers.

Solutions for Complex Bulk Solids Material Processing

Spiroflow is a member of the May River family, a group of process equipment manufacturing brands that include Cablevey, Kason, and Marion. This partnership provides sophisticated material handling equipment and engineering expertise to effectively tackle the most intricate requirements of bulk solids material processing.

Aligned with Cablevey Conveyors, Spiroflow, and other leading brands, AHS is a pioneer in automation solutions and specialized material handling equipment. Serving regulated markets like food, pharmaceuticals, nutraceuticals, specialty chemicals, and general industrial processing, AHS is your partner for cutting-edge conveyor solutions.

Commitment, Quality, Reliability & Service

Spiroflow’s conveying and weighing systems operate globally, renowned for their exceptional versatility and extended durability in the most challenging environments. Whether in the realms of food, chemicals, plastics, building materials, or minerals, Spiroflow stands ready to address a diverse range of handling requirements.

The core of every Spiroflow equipment is a set of primary design principles that prioritize dust-free handling and hygienic operation. Our product lineup goes beyond state-of-the-art automatic industrial conveyor systems. It also includes fully compatible weighing equipment designed for diverse applications. This extends from the batch processing of ingredients to the filling and controlled emptying of FIBCs or bags. These innovations are backed by a cutting-edge design, manufacturing, testing, and installation facility and supported by a responsive spares and service network.

Our unwavering commitment to excellence is sustained through an ongoing development program utilizing CAD design facilities and rigorous material testing procedures. The design of our conveying and weighing systems prioritizes a minimal number of working parts, ensuring maximum reliability in operation. Simplicity in operation, ease of cleaning and maintenance, and robust construction collectively contribute to a prolonged working life with minimal downtime.

The group of process equipment manufacturing brands under the May River umbrella, including Cablevey, Spiroflow, Kason, and Marion, provides top-tier advanced material handling equipment and engineering expertise to meet the intricate requirements of bulk solids material processing in various industries.

FOOD

- Bakery Products & Ingredients

- Snack Foods

- Food Products

- Sugar & Confectionery

- Beverage including Coffee & Tea

- Vitamins & Supplements

- Pet Food & Animal Feed

CHEMICAL

- General Chemicals

- Organic & Inorganic Chemicals

- Agricultural Chemicals

- Plastics, Polymers & Rubber

- Paints, Pigments & Coatings

- Resins

CONSUMER PRODUCTS

- Glass & Ceramics

- Building Products

- Pulp, Paper & Wood Products

- Cosmetics & Personal Care

- Pharmaceutical

OTHER

- Electronics

- Energy & Power

- Environmental

- Mining, Minerals & Metals

- Recycling

- Water Treatment

Spiroflow remains committed to continuous innovation, boasting a collection of patents linked to our cutting-edge products. The following is an up-to-date inventory of our presently active patents:

- US 5,947,333 – Bulk Bag Discharge System & Method

- US 6,076,704 – Bulk Bag Discharge System & Method

- US 6,138,443 – Bag Discharge Apparatus

- US 6,227,408 – Method & Apparatus for Discharging Bags

- US 6,439,377 – Tension Control Apparatus & Method for Aero Mechanical Conveyor

- US 6,564,534 – Bag Filling Apparatus

- US 6,598,736 – Tension Control Apparatus & Method for Aero Mechanical Conveyor

- US 7,165,498 – Vibrating Table Assembly for Bag Filling Apparatus

- US 7,267,144 – Bulk Bag Filling System

- US 7,798,313 – Dynamic Tension Control Apparatus & Method for Aero Mechanical Conveyor

- US 8,327,890 – Modular Bag Filling Apparatus

- US 8,777,060 – Discharger for Side Secured Bag Spout

- US 9,033,136 – Tensioning Assembly for Cable Drag Conveyor with Tensioning Assembly & Method of Controlling Tension in a Cable Drag Conveyor

- CA 2,436,267 – Vibrating Table Assembly for Bag Filling Apparatus

- CA 2,618,865 – Modular Bag Filling Apparatus

- GB 2,363,787B – Bag Discharge Apparatus

- GB 1,245,509 – Dynamic Tension Control Apparatus & Method for Aero Mechanical Conveyor