Exploring the optimal materials for a structural drag chain conveyor is key to maximizing its efficiency and longevity. This guide dives into the best materials suited for these conveyor technologies, emphasizing durability, cost-effectiveness, and compatibility with various industrial applications. Understanding the strengths and limitations of different materials will ensure your conveyor system operates at peak performance, delivering reliable and effective material handling solutions.

Heavy-Duty Structural Drag Chain Conveyor – A Problem-Solver for Conveyance of Any Material Type

What are the best materials for a structural drag chain conveyor? These industrial conveyor systems are problem solvers in a pipeline. That’s our nickname for them, and there’s a good reason for it. If there’s a material or product that won’t convey well in another type of conveyor, an ultra-heavy-duty structural drag chain conveyor built with schedule 40 pipe will likely get the job done.

At Spiroflow, we have more than 45 years of experience providing processors with the best conveyor solutions possible. We know how important the conveyance of your product is to your bottom line. Running the wrong type of material inside a conveyor can cause damage to the equipment and result in system downtime, but also damage the materials that were conveyed. That isn’t much of a concern if you partner with Spiroflow, one of the leading conveyor manufacturers.

Where Do Drag Chain Conveyors Fit in a Production Process?

Flexibility in the layout is a key advantage of our structural drag chain conveyor solutions, known as Dynaflow® conveyors. These industrial conveyor systems, which operate dust-free, can navigate three planes, offering processors versatile layout possibilities. Our conveyors boast a maximum circuit length of 400 ft (120 m), split equally between 200 ft (60 m) for the outward journey and 200 ft (60 m) for the return. For extended distances, it’s possible to connect multiple conveyor technologies end-to-end.

Designed with the capability for multiple inlets and outlets, these conveyors can be configured for metered or flood feeding. Structural drag chain conveyors are also fully compatible with a range of equipment, including bulk bag fillers, bulk bag dischargers, additional conveyors, and various other processing machinery. Here are other important features of these conveyors.

Ultra-Heavy-Duty Construction

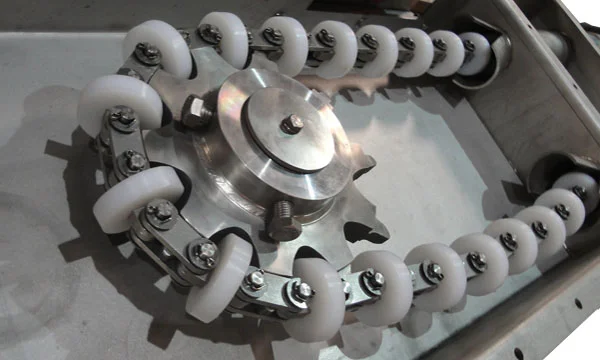

What are they made of? Structural drag chain conveyors earn their label as ultra-heavy-duty process equipment. These Spiroflow conveyor technologies are built with schedule 40 steel pipe and steel chain fitted with UHMWPE or steel discs.

Varying Speed and Capacity

Conveyor speeds will vary depending on the size of the pipe and material you are running. Conveying speeds can reach up to 50 ft/min (15 m/min), and capacities typically reach 10 ft3/min (0.28 m3/min). Operators always have the option to run the conveyor at slower speeds if there’s concern over product degradation.

Types of Materials That Are Best Conveyed in a Heavy-Duty Structural Drag Chain Conveyor

Drag chain conveyors operating within the confines of a pipe are the workhorses of the bulk material handling industry. They are almost a catchall in the conveying world. Here’s what we mean by that. Sludge-like materials won’t convey well in a flexible screw conveyor, cable drag, or an aero-mechanical conveyor.

However, they will convey nicely inside a structural drag chain conveyor. This is also the case with cohesive and abrasive materials. The same principle applies to anything considered a heavy-duty material. We could list all of the materials conveyable by this conveyor system, but there are too many to mention in this blog post. Instead, here’s a list of characteristics of a material that will work for structural drag chain conveyors:

- Abrasive,

- Cohesive,

- Dry,

- Fragile,

- Hot up to 420˚F (216˚C),

- Hygroscopic,

- Moist,

- Sludge.

Which Materials Shouldn’t Be Conveyed By Structural Drag Chain Conveyors?

Some types of products should stay out of these conveyors. Fine particles aren’t recommended, and our conveyor manufacturers at Spiroflow recommend material testing for slurries. The construction of structural drag chain conveyors also doesn’t lend itself to sanitary applications. So, ideally, food products should be kept out of these conveyors. Still, we should note that running a material test is important no matter what product you’re planning to convey.

The Importance of a Material Test

If it seems like a structural drag chain conveyor might be useful in your production process, reach out to trusted conveyor systems manufacturers like our team at Spiroflow, and run a material test. This is an important step in the design process. Everyone involved in creating conveyor solutions wants the installation and execution of your project to be successful. Utilizing a test lab is a great way to make sure this happens.

Should You Consider Some Other Conveying Options?

A structural drag chain conveyor is a serious investment. They are among the most expensive conveyor technologies out there. In some cases, other industrial conveyor systems can do the same job at a lower cost. A reliable manufacturer with expertise in many different mechanical conveyor solutions can make a recommendation to you based on your application requirements.

Contact Spiroflow for Outstanding Industrial Conveyor Systems

At Spiroflow, we specialize in delivering exceptional industrial conveyor systems tailored to meet the unique demands of your operations. Our team of experts is committed to providing innovative solutions that enhance efficiency, safety, and productivity for various applications.

Whether you need assistance with mechanical conveying, bulk bag filling or discharging, or even integrating control systems, Spiroflow has the expertise and technology to support your goals. Contact us today to discover how our state-of-the-art conveyor solutions can transform your business operations. Let Spiroflow be your partner in achieving operational excellence and driving your company forward.

FAQ

What Are the Best Materials for a Structural Drag Chain Conveyor?

Structural drag chain conveyors are designed to handle a wide range of materials, making them highly versatile for industrial use. Ideal materials for these conveyors include abrasive, cohesive, dry, fragile, hygroscopic, moist, sludge, and materials that can withstand temperatures up to 420˚F (216˚C). Their robust construction allows them to effectively convey these diverse material types without causing damage to the conveyor system or the materials themselves.

Where Do Structural Drag Chain Conveyors Fit in a Production Process?

Structural drag chain conveyors offer flexibility in layout design, capable of operating in three planes. This versatility allows for their integration into various stages of a production process, whether it be for initial material handling, intermediate processing, or final packaging. Their compatibility with multiple inlets and outlets and the ability to connect with other equipment make them a top choice for complex systems requiring efficient material transfer.

What Materials Should Not Be Conveyed By Structural Drag Chain Conveyors?

While structural drag chain conveyors are compatible with a broad range of materials, they are not suitable for conveying fine particles and should not be used for sanitary applications such as food products. Material testing is recommended for slurries to determine their suitability for this type of conveyor. It’s essential to consult with conveyor manufacturers like Spiroflow to identify the best conveying solution for specific materials.

Why Is a Material Test Important?

Conducting a material test is a crucial step in determining the compatibility of a structural drag chain conveyor with your specific materials. This process helps ensure that the conveyor system will operate efficiently and effectively without causing damage to the materials or equipment. Spiroflow offers material testing to guarantee the successful implementation of our conveyor solutions in your production process.

Should You Consider Other Conveying Options?

Although structural drag chain conveyors are a significant investment and among the most expensive options available, they are not always the best solution for every application. Alternative conveyor technologies might offer similar benefits at a lower cost, depending on your specific requirements. Consulting with experienced conveyor systems manufacturers like Spiroflow can help you identify the most cost-effective and efficient solution for your needs.