Cablevey® Cable Drag Conveyors

System OVerview

Cablevey Conveyors specializes in manufacturing Cablevey cable drag conveyors – tubular conveyor systems known for their gentle handling, ideal for installations requiring multi-plane conveying. These conveyor belt systems are proficient in transporting fragile bulk products from multiple in-feed points to multiple discharge points, ensuring minimal damage over long distances.

Their tubular conveying system stands out in the realm of industrial conveyor systems, moving materials and product blends in environments free from dust and contamination. These automated conveyor systems are designed with a focus on maintaining product integrity.

The belt conveyor system from Cablevey is tailored for the delicate transport of sensitive, breakable, and specialized bulk materials throughout the production and packaging phases. Offering conveyor solutions that include complete material batch transfer, these systems are a testament to advanced conveyor engineering and conveyor manufacturing. They ensure product integrity from various in-feed points to multiple discharge points with little to no damage, showcasing the efficiency of automatic conveyor systems.

FEATURES OF CABLEVEY CABLE DRAG CONVEYORS

- Reduce waste by delicately handling fragile materials and preserving blends.

- Utilize plant space effectively with flexible layouts, including intricate circuits across three planes and portable designs.

- Enhance processing efficiency with the ability to handle dry, moist, or wet materials through multiple inlets and outlets.

- Ensure plant safety and cleanliness with a dust-free, contamination-free, and fully enclosed conveyance system.

- Boost return on investment with rapid, efficient conveying capabilities of up to 11 ft³/min (0.31 m³/min), low power usage, extended cable durability, and continuous, reliable operation without the need for filters or cyclones.

HOW IT WORKS & BENEFITS

Our cable and tube conveyor technology incorporates a unique blend of conveyor belts and tubes, featuring cables with discs placed at specific intervals inside the tubes. This innovative design ensures materials are smoothly transported from inlets to outlets, securely held between the discs in an enclosed environment. Unlike systems where materials are agitated or pushed through turns, ours move products without any jolting, harsh movements, stress, or friction. This method significantly reduces breakage, making it crucial for fragile materials where gentle handling can be the key factor between profit and loss in conveyor belt solutions and conveyor technologies.

Our innovative conveyor belt systems transport materials slowly and delicately in enclosed tubes, greatly minimizing material damage and waste. This approach leads to superior product quality and enhanced profitability.

Our conveyor solutions encapsulate materials within a sealed tube, safeguarding both the materials and blends from external elements and protecting operators from dust exposure.

Featuring an enclosed and hygienic design, our industrial conveyor systems ensure materials are securely contained, minimizing contamination risks and contributing to a cleaner processing environment.

Offering various cleaning methods, including wet, dry, and in-place options, our automated conveyor systems simplify the cleaning process, cutting down on time, labor, and resources.

Thanks to their streamlined and straightforward design, these conveyor technologies have fewer components, boast higher reliability, and require minimal maintenance, leading to reduced costs and lowered risk of downtime.

Our automatic conveyor system is designed for efficiency, utilizing lower horsepower engines, demanding less energy, and generating minimal heat.

With the capability of multiple inlets and discharges, a single system can offer extensive layout flexibility, potentially replacing multiple units.

Our conveyors are adept at moving products in any direction, including multi-directional and vertical movements, offering unmatched versatility in system design.

APPLICATIONS

CONFIGURATIONS

With the capability of operating across three planes, tubular conveyor systems offer a vast array of layout possibilities. Our expert engineers will assess your specific application needs and any site limitations to devise the most suitable layout. While we have a range of typical circuits, including the ones listed below, this selection is just a starting point and not exhaustive of our conveyor solutions and conveyor engineering capabilities.

MODELS & SPECIFICATIONS

Our Cablevey cable drag conveyors come in a range of tube sizes from 2 inches to 8 inches in diameter. Our engineering team is on hand to advise on the best size, tube type, and additional options for your specific needs.

COMPONENTS & OPTIONS

Our essential components are designed for maximum flexibility and modularity, ensuring convenient adaptability to meet the demands of the factory floor.

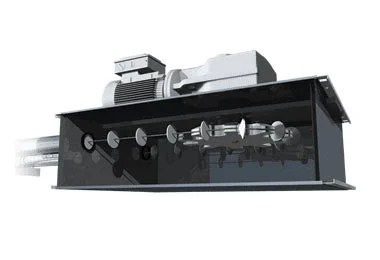

1. Drive Unit: An electric gear motor attached to a stainless steel frame propels the cable through the drive unit. The cable is designed to enter and exit through any tube port, accommodating the specific requirements of your layout.

2. Funnel: Funnels play a crucial role in channeling material from rotary discharges and/or cleanouts. We offer funnel outlets in an extensive range of sizes and connection types tailored to suit your specific requirements.

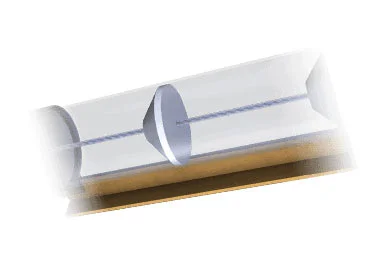

3. Inspection Section: This section features a food-grade plastic tube, enabling visibility of the conveyed product and the monitoring of the cleaning process. It can be installed in either vertical or horizontal orientations, depending on your preferences.

4. Sweep: Sweeps are designed to alter the direction of travel to any angle you require. Available in a variety of angles ranging from 0 to 90 degrees and in several radius sizes, they are adaptable to fit even in constrained spaces.

5. Compression Coupler: Equipped with a food-grade rubber gasket, this coupler guarantees an effective seal against air, water, and dust. It precisely aligns the tubes, providing a seamless path for the discs to travel through.

6. Inlet: Our inlets come in an extensive range of lengths to meet diverse requirements. The sides of these inlets are designed with varying slopes to suit different material flow characteristics. If needed, multiple inlets can be incorporated into the system.

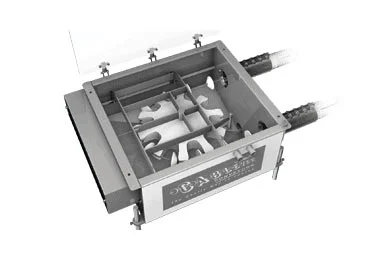

7. Turnaround: This component includes a sprocket that is essential for reversing the cable's direction from the return side back to the product conveying side of the system. The sprocket is mounted on a specially designed mechanism that ensures the correct tension of the cable.

8. Discharge: This feature is designed with the capability to be either open or closed, providing the flexibility to allow materials to continue through or exit the conveyor at that specific point.

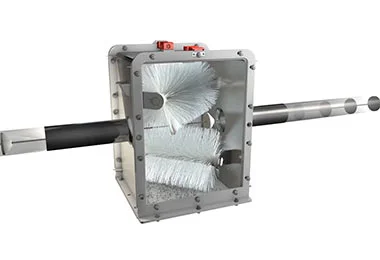

9. Brush Box: This component is a housing through which the cable and discs pass. It contains two roller brushes positioned above and below the cable and discs. As the cable moves, the brushes are turned by the discs, effectively removing any adhering particles and directing them into a waste chute for disposal.

FAQ

What Is the Maximum Operating Speed of a Cablevey Conveyor?

Should I Choose a Larger Conveyor for Certain Types of Materials?

Yes, for materials that are sluggish, sticky, abrasive, or if the conveyor will be used heavily, it’s advisable to use a larger conveyor at a slower speed for optimal handling and longevity.

When Is It Suitable to Use Smaller Conveyor Sizes and Faster Cable Speeds?

Smaller conveyor sizes and faster cable speeds are best for free-flowing, non-abrasive materials or when the conveyor’s duty cycle is expected to be low.

How Can Future Capacity Requirements Be Addressed?

Consider installing a larger conveyor at a lower speed initially. You can increase the cable speed later with a variable frequency drive or gearing change to accommodate higher capacity needs.

How Do Surge Hoppers Affect the Choice of Conveyor Size?

Surge hoppers can regulate feeding, leading to more consistent material flow. This can allow for the use of a smaller conveyor in some cases.

Can I Adjust the Speed of the Conveyor After Installation?

Yes, the speed of the conveyor can be adjusted post-installation using a variable frequency drive or by changing the gearing, allowing for increased flexibility in handling varying capacities.