Flexible Screw Covneyors

System OVerview

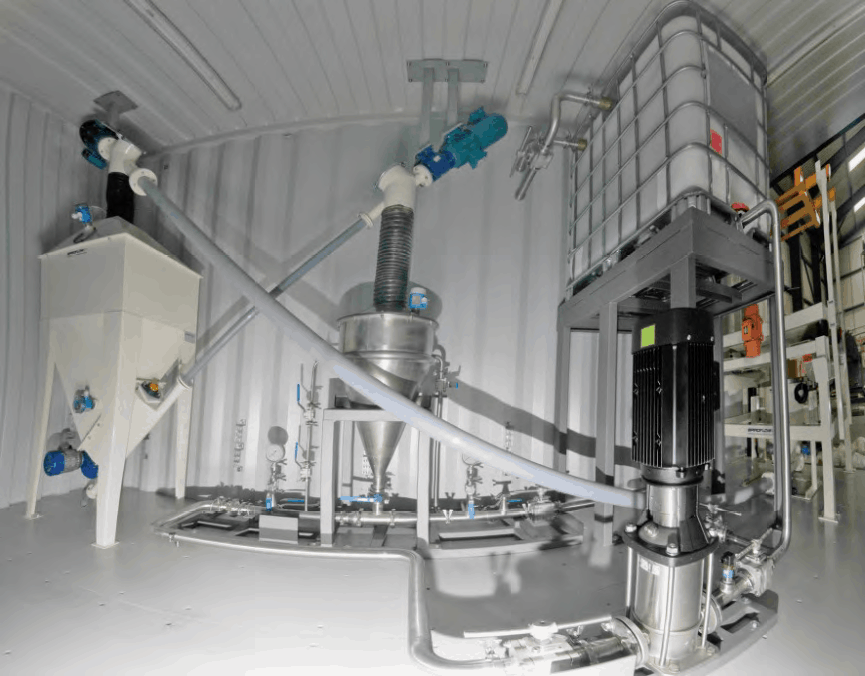

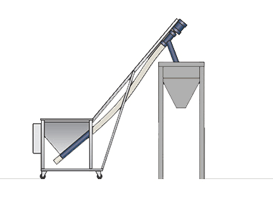

Welcome to Spiroflow’s world of flexible screw conveyors, where versatility meets efficiency. Our flexible screw conveyors are designed to transport materials in any direction, from horizontal to vertical, making them ideal for various applications. Explore the simplicity of their design, gentle product handling, and a cost-effective, low-maintenance operation. Discover how Spiroflow’s conveyor technologies can revolutionize your material handling needs.

Spiroflow's Flexible Screw Conveyors Are Just That - Flexible

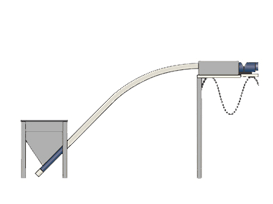

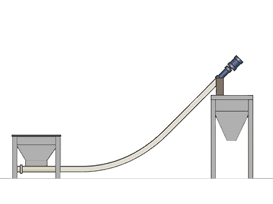

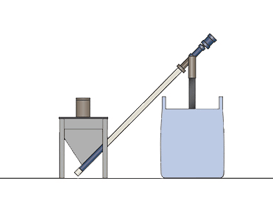

Flexible screw conveyors offer versatile material conveyance capabilities, accommodating various directions from horizontal to vertical, navigating around fixed obstacles, and seamlessly transferring between rooms. They excel in elevating materials from bag dump stations or storage bins and can transport products at ceiling height to supply processing or packaging machines.

These conveyors maintain material homogeneity by continuously remixing it via the rotating spiral, effectively preventing product segregation. Furthermore, they prove to be a highly cost-effective solution for conveying dry bulk solids and ingredients.

Flexible Screw Conveyors are known by several names, such as flexible screw conveyor, flexible auger, flex conveyor, flexible spiral conveyor, helical conveyor, or helix.

Check Out All the Features of Spiroflow Flexible Screw Conveyor

- Design Simplicity

- Greater Hygiene

- Dust-free Operation

- Easy to Clean

- Constant Remixing

- Low Cost

- Low Maintenance

- Heavy-duty

Flexible Screw Conveyors Provide Continuous Mixing and Blending

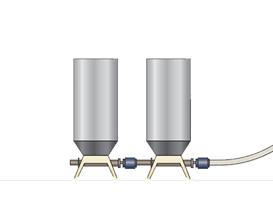

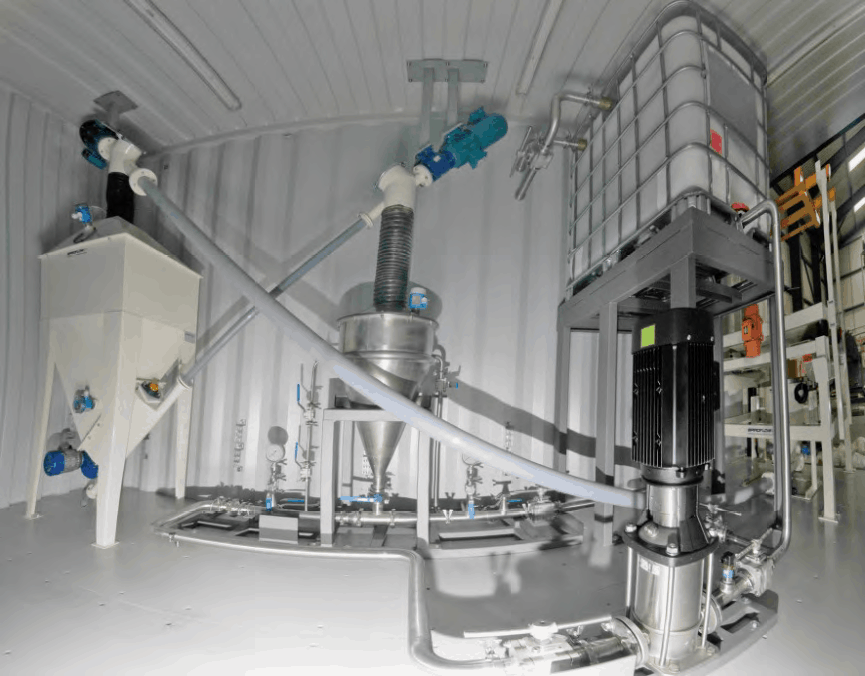

Spiroflow, a leading name among conveyor systems manufacturers, introduces its innovative inline twin screw (ITS) continuous proportional blender. This cutting-edge blender excels in achieving comprehensive mixing within a short material flow distance. It boasts a unique stepless adjustability feature that enables precise blend ratios.

Engineered to handle a wide range of materials, including free-flowing, granular, flake, and pellet substances, the Spiroflow ITS stands out with an outstanding accuracy rate. This blender is tailor-made for various applications in industries such as food, chemical, construction, and more, accommodating a diverse range of specifications.

Innovative Operation of ITS

Within the realm of industrial conveyor systems, Spiroflow ITS presents an inventive solution. This innovative system takes a unique approach by introducing the secondary ingredient directly into the core of the primary ingredient’s flow. It incorporates two rotating spiral-type conveyors with differing diameters. Notably, the steel tube of the smaller conveyor is carefully positioned within the spiral of the larger conveyor, extending beyond the inlet hopper.

This meticulous design ensures that the minor ingredient is introduced precisely at the optimal point for thorough mixing within the primary ingredient. As a result of the Spiroflow ITS’s exceptional mechanical action, it effectively addresses and eliminates ingredient stratification, a persistent challenge encountered in various other mixer types.

Count on High Output Rates

Suitable for Food and Pharmaceutical Applications

Let's See How It Works and What Benefits You Will Enjoy

Gentle Product Handling

Design Simplicity

Dust-free Operation

Easy to Clean

Low Maintenance

The Spiroflow flexible screw conveyor operates smoothly thanks to its durable inner spiral, serving as the sole moving component in the system.

Heavy-duty

We provide screw conveyors featuring ultra-high-molecular-weight polyethylene (UHMWPE) tubes designed for abrasive or high-density materials and heavy-duty work

For handling the most abrasive substances like metals, aggregates, and materials such as glass cullet, we offer the Rhinoveyor Flexible Screw Conveyor. This specialized system includes an abrasion-resistant rubber conveying tube, along with a heavy-duty spiral. Comprehensive testing and operational experience have demonstrated that our RHINOVEYOR conveying tubes significantly outlast standard UHMWPE plastic tubes, particularly in aggressive applications.

Constant Remixing

Explore Different Application Possibilities

Even though traditional conveyor belts are still many businesses’ first choice, nowadays, flexible screw conveyors are becoming more popular. This is a result of their versatility and ability to handle a wide range of particle sizes, bulk densities, and flow properties. That’s why Spiroflow flexible screw conveyors are installed around the world in numerous different industries.

Food

Water Treatment

Minerals and Ceramics

Chemicals

Plastics Rubbers

Pharmaceuticals

We Offer Versatile Configurations

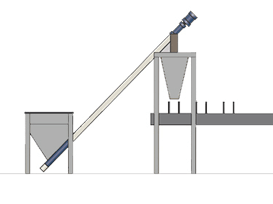

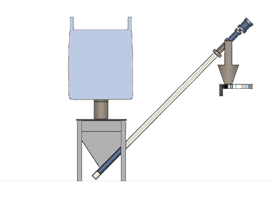

Feeding Filling Machinery

Horizontal Outlet for Restricted Headroom

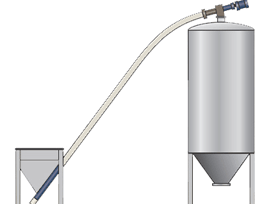

Conveying from Hopper to Process

Controlled Feeding & Dosing from Bulk Bags

Multi-Infeed Conveyor

Loading Silos

Filling Bulk Bags

Mobile Conveyors

MODELS & SPECIFICATIONS

Standard Construction & Components:

- Tubes: Food grade UHMWPE.

- Spirals: Carbon or mild steel with the option to upgrade to stainless steel.

- Spiral Profiles: Round, Heavy-duty Round, Flat, Proscrew Beveled Edge

Electrical Requirements:

- 2-7.5 hp (1.5-5.6 kW) Motor

- Motor sized to application

Pneumatic Requirements

- 60-80 psi if air agitation is specified

Inlets, Outlets & Feeding

- Multiple inlets & outlets,

- The conveyor is designed to be run fully charged & can be run with a full head of material in a hopper,

- Vibration, air fluidizers, or agitators can be fitted to assist with poor-flowing products,

- Inlets can be fitted with baffles, lids, hoppers, agitators, etc. Custom designs available.

Spiral Profiles & Tube Selection

For most applications, the standard round spiral is suitable, combining strength and flexibility. Flat section spirals are recommended for certain light or aerated products.The Proscrew beveled profile is used for conveying difficult materials such as iron oxide. The semi-rigid construction enables steep conveying angles to be achieved without bends.

The Centre Core is used for very light materials that fluidize readily and for conveyors inclined more than 60°. They are also used to prevent flooding/overfeeding of certain solids in short or horizontal conveyors.All spirals are heat treated to provide strength and long life. Heavy duty spirals are also available for certain high density or aggressive materials.

Flexible screw conveyor tubes are available in UHMWPE, carbon steel (mild steel), 304 stainless steel or the industry’s only ‘Rhinoveyor’ rubber tubing (used when conveying abrasive material).

What Spiral Profiles and Tube Options You Have to Choose From?

The standard round spiral is suitable for most applications, offering a balance of strength and flexibility. Flat-section spirals work well for lightweight or aerated products. Proscrew beveled profiles are effective for challenging materials like iron oxide due to their semi-rigid construction, enabling steep conveying angles without bends.

Center cores are ideal for very lightweight, easily fluidized materials and for conveyors inclined over 60°. They also prevent flooding or overfeeding in short or horizontal conveyors. All spirals undergo heat treatment for durability. Heavy-duty spirals are available for high-density or aggressive materials.

Flexible screw conveyor tubes come in UHMWPE, carbon steel (mild steel), or 304 stainless steel.