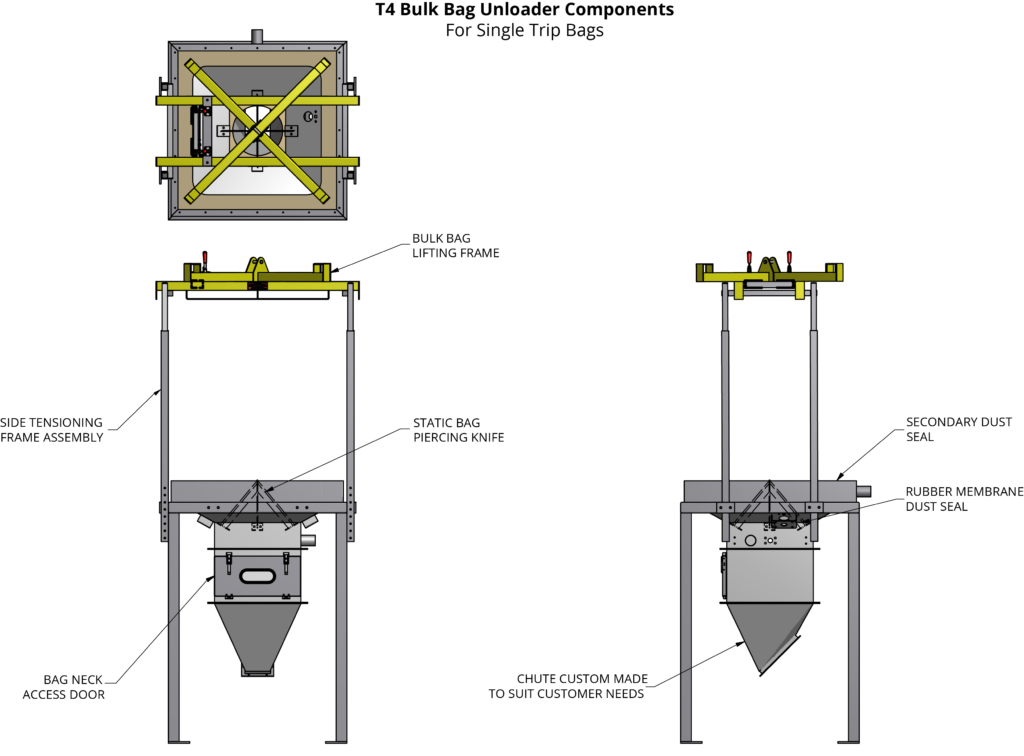

T4 Unloader for Single Trip Bags

System OVerview

Single trip bulk bags are widely used in plant environments for low value or hazardous products which require a dust-free and controllable emptying method.

Our T4 bulk bag unloader can empty these disposable bags, which have no bottom spout, without waste or spills, even those containing poor flowing products, using various discharge aids and transfer conveyors to suit the application.

This model can be provided with a mobile frame, an overhead electric bag hoist and/or a double dust suppression membrane. Of course, custom designs are always available.

Features

- Static or pneumatic knife

- Vibratory discharge aid

HOW IT WORKS & BENEFITS

The T4 Single-Trip Bulk Bag Unloader is used with single-trip (disposable) bags that have no bottom spout.

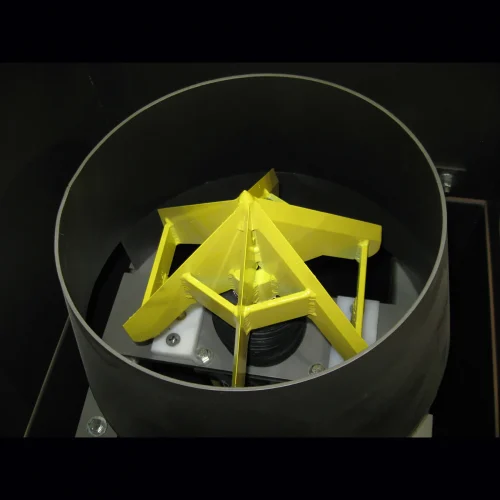

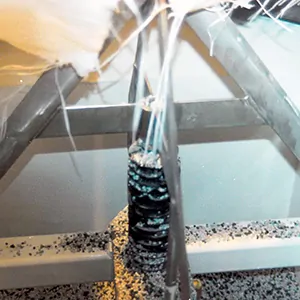

The bulk bag is sealed on the outer edge by a rubber membrane as it is lowered into the frame where a pyramid-shaped knife assembly pierces the bag bottom. Bags can be lowered with a forklift or the optional electric hoist. This bulk bag unloader is of all welded construction with a steel support dish that will accommodate any spout less bulk bag. The heavy-duty 3in./ 80 mm square steel tube frame is welded directly to the support dish. The discharge of the chute is custom made to fit the application.

How It Works:

- A bulk bag of product is fitted with the Bag Lifting Frame.

- The operator lifts the bulk bag into place with a forklift.

- The Lifting Frame sits on the Side Tensioning Frame if included.

- The weight of the bag contacts a static knife mounted on the Support Dish pierces the bottom of the bulk bag.

- The solid welded dish safely supports the weight of the bag.

The T4 consists of a robust frame and discharge dish with a knife to pierce the base of the bag. A double membrane with dust extraction facility ensures total containment of dust emitted during bag piercing operation.

The optional double membrane ensures that the bag sits deep within the dish and no dust escapes during discharge.

The bag is ruptured by the knife and product flows from the discharge dish into the integral transfer conveyor.

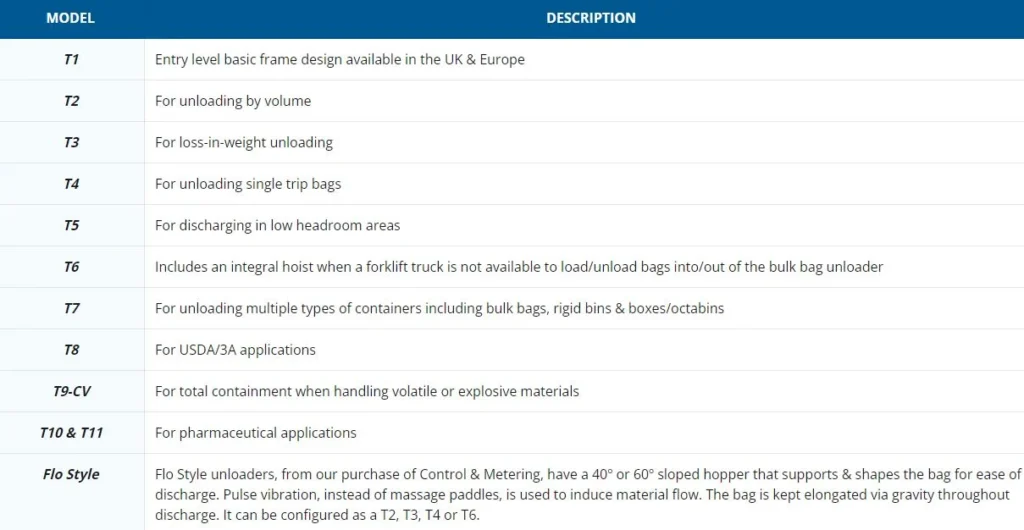

MODELS & SPECIFICATIONS

The T4 bulk bag unloader is one of several designs we offer. Features of our various models are typically mixed and matched to accommodate specific application needs. And, of course, we regularly build custom designs. Here is a list of our basic models. Your Spiroflow Sales Engineer will evaluate your needs and recommend the best configuration to do the job.

SPECIFICATIONS

STANDARD MATERIALS OF CONSTRUCTION

- Carbon/mild steel is standard.

- Optional 304 or 316 stainless steel is available.

PNEUMATIC REQUIREMENTS

- Side Massage: 80 PSI (5.5 Bar) at 2 CFM (56.6 L)/Cycle

- Corner Massage: 80 PSI (5.5 Bar) at 4 CFM (113.3 L)/Cycle

- Bottom/Dish Massage: 80 PSI (5.5 Bar) at 1 CFM (28 L)/Cycle

- Spout Closure Bars: 80 PSI (5.5 Bar) at 1 CFM (28 L)/Cycle

- Chute/Hopper Vibrator: 80 PSI (5.5 Bar) at 3 CFM (85 L)/Cycle

- Dust Collector: 80 PSI (5.5 Bar) at 35 CFM (991 L)/Cycle

ELECTRICAL REQUIREMENTS

- Optional Chute/Hopper Vibrator: 0.13 hp (.1 kW)

- Optional Hopper Agitator: 0.33 hp (.25 kW)

- Optional NEMA 4/ATEX Panel with ON/OFF Switch for Vibrator or Agitator: 0.33 hp (.25 kW)

- Optional Dust Collector: 1.5 hp (1.1 kW)

- Optional Level Probe: 24V DC

DUST CONTROL/AIR DISPLACEMENT

- Dust Extraction Port Optional Integrated

- Dust Collector: NEMA 4, TEFC (Stainless Steel Only)

- Optional Integrated Dust Collector: XP (Stainless Steel Only)

- Optional Free-Standing Dust Collector: NEMA 4, TEFC (Stainless Steel Only)