With the use of bulk bags (or FIBCs) continuing to be a popular method of storing and moving materials, some businesses often struggle to discharge agglomerated or hardened solid material from their bulk bags. This is certainly the case for material such as hygroscopic chemicals, certain types of blends, heat-sensitive products and other materials prone to solidifying to the point where bulk bag dischargers are inefficient or completely ineffective. This is why Spiroflow’s bulk bag conditioner is the best.

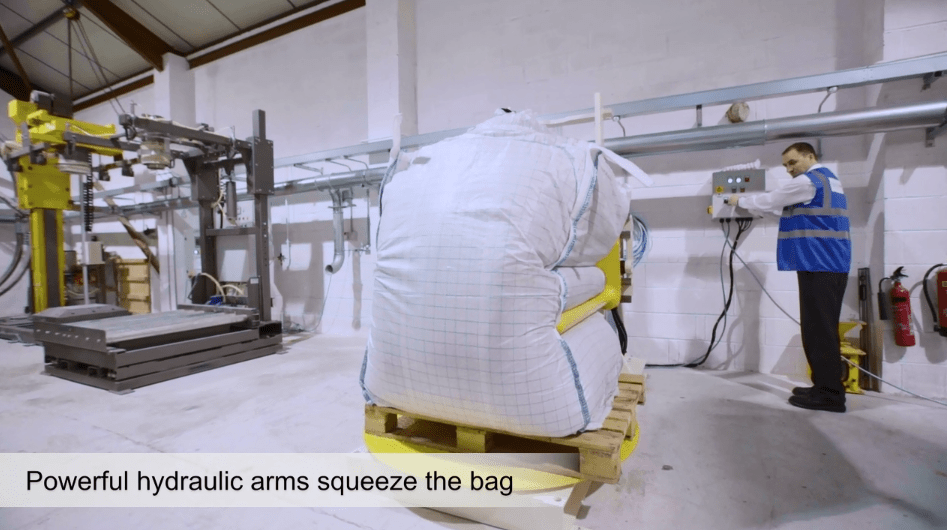

Spiroflow’s bulk bag conditioning system is a best-in-class solution to enable efficient break up of solid ingredients. Configured to meet operational requirements, the system uses either fixed or movable masts and can be integrated into an automated bulk bag discharging system, or as a manually operated free standing piece of equipment. The system consists of a robust frame structure with hydraulically actuated conditioning arms mounted on two opposing sides. The bag is usually placed between the two conditioning arms using a forklift, integral hoist, pallet truck or motorized conveyor. The conditioning arms then apply pressure in a squeezing motion, typically 2-3 squeezes to opposite sides of the bag, thereby breaking up the solidified material and allowing flow during discharge.

Other systems on the market use a flat plate instead of arms, which pushes down on material from the top; the downside of this method is that it can push large lumps of agglomerate further down the bag rather than break them up. An additional benefit of Spiroflow’s bulk bag conditioner is that the conditioning arms move the up and down the bag to loosen material, with the bag itself staying at ground level. From a safety perspective, this is a clear advantage when compared to alternative systems that hoist the bag into the air and move it up and down past ‘squeezer’ arms to break up material. This method can present a safety risk, should the bag become unstable.

As an added benefit, Spiroflow’s bulk bag conditioner is supplied with an integral turntable as standard, although can be removed as an option if required. Once the bulk bag is placed on the turntable, it can be spun 360 degrees to facilitate all round pressure from the conditioning arms to any part of the bag, thereby ensuring that no large lumps of material are missed. The turntable’s functionality can be used as an automated sequence if required. To view our product page click here.