Customer Requirements

A producer of kaolin was looking for a competitive edge in their very competitive market. Kaolin, commonly known as china clay, is one of the most abundant minerals on earth and is notoriously difficult to handle. The company’s final kaolin products are filled in bulk bags and shipped in shipping containers to customers all over the world.

The company had an in-house designed dual bulk bag filling system which required two operators and produced 7.2 filled bulk bags per hour. The process was slow to the point that operators would walk away and come back minutes later. The filling rate limited the company’s production and operator productivity.

KEY REQUIREMENTS:

- Fill bulk bags at 14,500lb/ 6500kg per hour using 2,500lb/ 1000kg bulk bags. This is a fill rate of 12 bags per hour.

- Densify the highly aerated kaolin clay within each bulk bag so that the bags are upright, evenly filled, safe and stable.

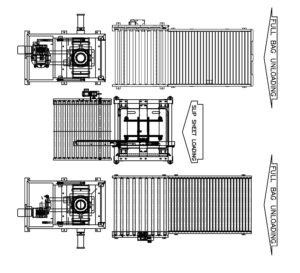

- Small footprint for container shipping to international customers.

- Automate the filling process to maximize operator safety and productivity.

- Minimize the required number of operators.

- Use a single PLC control panel to operate dual bulk bag filling systems.

- The control panel must communicate to their plant-wide DCS via an Ethernet connection.

Spiroflow Solution

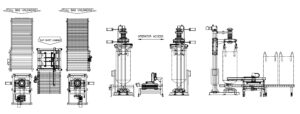

Our engineers evaluated the company’s needs and recommended a filling system based on their high-speed, densifying CTE Bulk Bag Filler. The CTE (Cone Table Elite) provides maximum product densification. This ensures that even the most difficult to fill products can safely be packaged in stable, uniformly filled bulk bags.

THE SYSTEM INCLUDED:

- Dual CTE bulk bag fillers

- An operator platform between the fillers

- A slip sheet dispenser beneath the operator platform

- An Automatic Bag Removal (ABR) shuttle between the two CTE fillers

- Two powered roller conveyors

- Two gravity roller conveyors with sensors

- A control panel with functions for automatic/manual operation

The Result

The bulk bag filling system worked so well that they have since added a second dual system. The second system, located in the same area, is a duplicate of the first but has a slightly different layout based on available space.

It utilizes hang weighing for even greater weighing accuracy and increased efficiency. The new filling system also has an updated heavy-duty Cone Table mounting system for maximum product deaeration and densification.