Customer Requirements

The challenge was to eliminate dust and reduce the amount of material handling for the raw ingredients handling operation of a leading pharmaceutical company.

Spiroflow was approached to offer a solution, not only because of their in-depth knowledge of powder handling, but also because of the comprehensive range of products they offer.

Spiroflow’s powder handling capabilities place much emphasis on containment and compliance with the ATEX and DSEAR Directives relating to the use of their equipment in hazardous environments such as where solvents may be present in pharmaceutical applications whether for cleaning or as part of the process.

Besides offering individual pieces of equipment, Spiroflow is well versed in the design, manufacture, installation and commissioning of complete, turnkey handling systems.

Spiroflow Solution

- Two materials are emptied into each of two separate and dedicated sack tip hoppers.

- These are connected to a central dust collection system to ensure no health risks to the operators who slit the bags open and empty their contents.

- Furthermore, there is also a provision for the empty bags to be disposed of directly into a sack compaction unit ready for sealing in polyethylene bags.

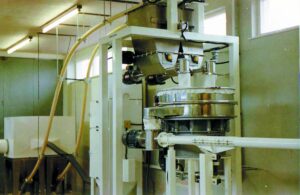

- Flexible Screw Conveyors below each hopper convey product to two separate weigh hoppers.

- The weigh hoppers control the conveyors and ensure the correct ratio of the two components.

- Once the correct weights have been verified, variable speed metering feeders below the weigh hoppers, with integral agitators to ensure consistent product flow, feed the products into a sifter.

- These metering feeder units, for the major and minor components, run at suitable speeds so that both products complete their discharge into the sifter simultaneously to achieve a homogenous pre-blend.

- A third Flexible Screw Conveyor feeds the pre-blended product to a mixer for final mixing/conditioning.

- This conveyor is pivoted horizontally for easy removal from service when the system is cleaned.