Customer Requirements

These units are designed for users who manually empty a relatively small number of bags into process hoppers, mixers or sieves. Investment in a bag dump station is quickly recouped, where more expensive and complex automatic equipment intended for continuous high volume operation cannot be justified.

Spiroflow Solution

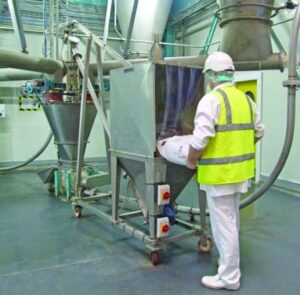

These units are designed for users who manually empty a relatively small number of bags into process hoppers, mixers or sieves. Investment in a bag dump station is quickly recouped, where more expensive and complex automatic equipment intended for continuous high volume operation cannot be justified.

- The basic bag dump station includes an open fronted bag dump cabinet with a dust extraction outlet for connection to a separate dust collector or existing extraction plant.

- A bag is placed on the mesh support shelf and manually slit.

- The contents fall directly into the inlet of a flexible screw, aero mechanical or vacuum conveyor. +-

- The type and size of the conveyor is determined by the flow rate, conveying distance and flow properties of the product.

- A compaction unit for empty bags is a commonly specified option to ease disposal and further reduce dust.

- Once tipped, the empty is pushed to the back of the cabinet into a separate chamber housing a large diameter slow speed auger.

- This compresses the bag into a plastic tube which can be removed and tied off when full.

Spiroflow bag dump stations eliminate dust problems caused by manually emptying bags and also the subsequent disposal of empty bags. This insures a healthy environment is maintained in the process area, reduces maintenance and repair problems caused by powder contamination to surrounding machinery.

Another version of our bag dump stations includes a cabinet with a hinged door and bag support mesh shelf. Large integral cartridge fillers are fitted in the back of the cabinet. A side mounted empty bag compactor can also be fitted.

Features & Options

• Robust Bag Support Mesh Shelf

• Empty Bag Compaction Auger with Safety Cage

• Vacuum Bag Lifter

• Hinged Door or Strip Curtain

• Safety Knife for Bag Slitting

• Mobile Frame

• Integral Conveyor (Flexible Screw or Aero Mechanical)

Dust Extraction Methods

• Integral Filter Cartridges

• Top Mounted Filter Unit

• Hepa Filter Unit

• Mobile Frame

• Simple Spigot for Connection to Plant Dust Extraction System