ITS Continuous Blender

This insures that the flow of this minor ingredient is introduced into that of the primary one at the optimum point for thorough mixing.

Stratification of different ingredients, which occurs with other types of mixers, is avoided by the unique design & mechanical action of the Spiroflow ITS.

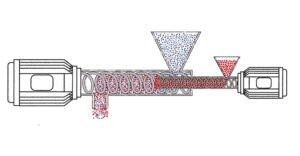

Thorough mixing is achieved over a short length of material flow with the Spiroflow ITS in-line twin screw continuous proportional blender. It is steplessly adjustable for any blend ratio and is designed for use with any free flowing powder, granular, flake or pelleted materials.

Accuracy of the Spiroflow ITS is to 2%, depending on material and application, making it suitable for a wide range of uses in the food, chemical, building products and other process industries.

Spiroflow Solution

The Spiroflow ITS incorporates a novel principle in that the feed of the secondary ingredient is introduced directly into the center of the flow of the primary ingredient. The unit comprises two rotating spiral type conveyors of different diameters. The steel tube of the smaller conveyor is located within the spiral of the other.

A system designed for a leading detergents manufacturer involved powder, granulate and ‘re-blend’ product being simultaneously blended and conveyed, both operations being performed by the rotating spirals.

Product ratios were as follows:

- Concentrate: Free flowing powder with a bulk density of 50lb/ cu.ft / 800kg/m3

- Feed rate: 440lb/hr / 200kg/hr using a Model 214 conveyor

- Major ingredient A: Granulate with a bulk density of 56lb/cu.ft 890kg/m3

- Feed rate: 45 tons/hr / 40tonne /hr using a Model 412 conveyor

- Major ingredient B: Re-blend product, variable bulk density

- Feed rate: 1300lb/hr / 600kg/hr using a Model 258 conveyor

Output Rates:

Spiroflow ITS Blenders are made of standard sized Spiroflow rotating spiral conveyors and can be designed for any required throughput up to a maximum of 10 tons/hr.

Food & Pharmaceutical Applications:

Sanitary versions of the Spiroflow ITS with quick release connectors, for ease of disassembly and cleaning, can be made in stainless steel for use

User Advantages

Mix quality can equal that of more expensive batch equipment

Short process length minimizes size of unit, saving floor space or simplifying overhead installation

Can be used effectively with two or more components of similar or greatly differing particulate size and density. For example, a powder can be thoroughly mixed with a large granulate and no separation of the two components will occur.

The Spiroflow ITS is recommended where other types of mixers may present difficulties in blending different particulate sizes. This is often the case where residual fines or dust must be blended with materials of much larger particulate size.

Little or no particulate breakdown during mixing even on friable materials