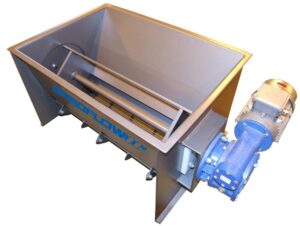

Friable Material Conditioner

At Spiroflow we are experts in promoting the flow of difficult materials whether it be from Bulk Bags or into one of our conveyors.

However, there are occasions when a particular material requires additional ‘conditioning’ ahead of processing or packaging. This is especially true in our global economy when so many materials are imported from far corners of the world and often have spent considerable time compacted in the humid hold of a ship. To meet this need, we have designed a new range of Friable Material Conditioners.

Our Friable Material Conditioner is furnished with a mesh to ensure only material ‘conditioned’ to the correct specification passes to process or packing.

We currently offer 3 standard models: FM100 (2,200 lb/hr), FM200 (4,400 lb/hr) and FM300 (6,600 lb/hr), but special versions can easily be made to fit any size and/or shape of hopper. Construction material choices include carbon steel, coated carbon steel, 304 or 316 grade stainless steel with a variety of finishes – all as the application dictates. Options include a pull out grid for easy cleaning or changing to a different material conditioning specification.

These Conditioners can be integrated into other Spiroflow products or available as stand-alone units.