Chainflow Drag Chain Conveyors

System OVerview

If you are in need of state-of-the-art, high-quality, and dependable conveyor belt solutions, we are conveyor systems manufacturers that offer our innovative Chainflow drag chain conveyors that will elevate your operations. Our specialized conveyors are carefully designed to serve an array of industries, blending innovation and technology. They economically convey hot, cold, or dry granules and powders, particularly fragile ones, and various plastics and chemicals.

Innovative Conveyor Technologies Optimize Efficiency in Dry Bulk and Powder Processing

Spiroflow’s Chainflow tubular drag chain conveyor is the latest option in our extensive offer of mechanical conveyor belt systems, made for the dry bulk powder and solids processing industry. The heavy-duty, hygienic, dust-free, totally enclosed Chainflow tubular drag conveyor conveys hot (up to 180°F/82°C), cold, or dry granules and powders economically, especially fragiles such as nuts, food ingredients, coffee beans, cereals, animal feed, pet food, as well as different plastics and chemicals. Our processors convey or batch ingredients with ease thanks to a layout-flexible contact chain made of crevice-free materials, and successfully carry unlimited amounts of non-cohesive dry granules and powders.

Features

- 24/7/365 heavy-duty high-load conveying

- Multiple outlets, multiple inlets, and 3-plane circuits allow for the greatly versatile layouts

- Gentle handling means maintaining of consistent mixtures while minimizing material breakage

- Completely enclosed design means no dust and contamination

- Automatic chain tensioning brings minimizing of operator maintenance while maximizing the life of tube, chain, and disc

HOW IT WORKS & BENEFITS

There are several benefits of Spiroflow’s Chainflow tubular chain drag conveyor, from efficiency to gentle handling of materials and products. Understanding how this system works will help you choose this solution for improved and streamlined production.

Fast and Efficient Conveying

Totally Enclosed, Dust-Free, Contamination-Free Handling

Gentle Product Handling and Maintaining Blends

Operate in Multiple Planes With Multiple Inlets and Outlets

Tubular drag conveyors are the only conveyors that can work in three planes. Thanks to the flexibility of the layout, our engineers are able to design complex circuits, eliminating transfer points while using a single drive.

The conveyor can fit with multiple-outlet applications so that one single conveyor can deliver materials to more than one point. Multiple inlets are also possible, but only one can be operational at any given time.

Dry, Moist, or Wet Materials

Operational Flexibility and Long Chain Life

Convey over long distances with maximum straight-line lengths of up to 250 ft (76m) per conveyor and link multiple conveyor solutions for longer distances. Enjoy the operational flexibility to stop and start under load and run empty with most materials. You can also flood or meter feed the conveyor based on your product flow characteristics. Maximize your use with a mobile design available for multiple in-plant applications or freight car and truck loading.

All chains used in our chain assembly are constructed from 304 or 316 stainless steel with one-piece USDA-accepted polyurethane molded discs secured at fixed intervals. With proper tensioning, end users can expect a very long chain life and minimal chain replacement expenditures.

Minimal Maintenance and 24/7/365 Reliability

Low Energy Consumption

No Filters or Cyclones

APPLICATIONS

CONFIGURATIONS

Because tubular drag conveyors can operate in three (3) planes there is an endless number of layout options. Our engineers will evaluate your application requirements and site restrictions to determine the optimal layout. Typical circuits include the layouts below, however, this is by no means a complete list.

MODELS & SPECIFICATIONS

Our Chainflow Drag Chain conveyor is offered in a 4” (100cm) size. Our engineers will access your application needs and recommend the optimal configuration and options.

Standard Construction & Components:

- Tubes: 304 Stainless Steel

- Chain: 304 Stainless Steel

- Discs: UHMWPE

- Drive assembly

- Automatic chain tensioner

- Sweeps at standard 90° angles

- Material feed inlet

- Material discharge outlet

Electrical Requirements:

- 3 -7.5 hp (2.2 – 5.6 kW) Motor

- The motor is sized to each application.

Pneumatic Requirements

- 60-80 psi

Inlets, Outlets & Feeding

- Multiple inlets & outlets are allowed.

- Material can be metered or flood fed. This is product dependent.

- Inlets can be fitted with baffles, lids, hoppers or agitators.

- Variable conveying rates. Custom designs are available.

COMPONENTS & OPTIONS

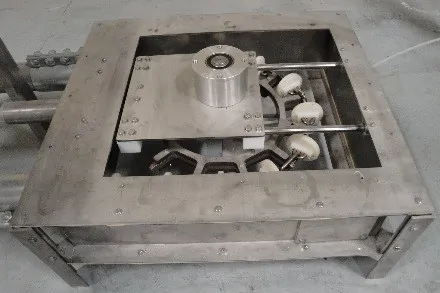

Spiroflow’s Chainflow tubular drag chain conveyor is designed to achieve gentle handling and low material degradation. A series of straight and curved tubes coupled to stainless steel housings form a circuit where the product can enter and exit through tube mounted chutes.

Conveying is achieved when material enters the space between discs molded to an endless chain that is contained within the circuit. The chain and discs are dragged through the circuit by a driven sprocket at one end. Additional sprockets can be added to the circuit to provide frictionless direction changes and reduce the load on the system. Continuous tension is applied to the chain via a patented pneumatically actuated tensioning assembly mounted in the 180° idler assembly included with the system.

Straight Tube Sections

Chain & Disc

Drive Housing & Outlet

Corner Housing in Production

Inlet Housing & Adjustable Baffle

Site Glass/Inspection Port

Return Housing & Tensioner

Tube Joiner & Tube Support

Chain in the Sprocket

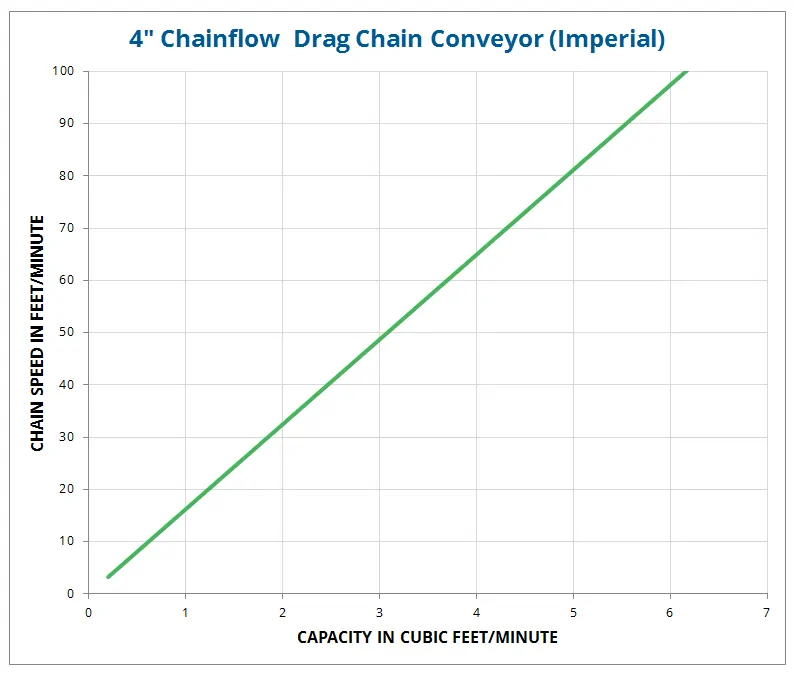

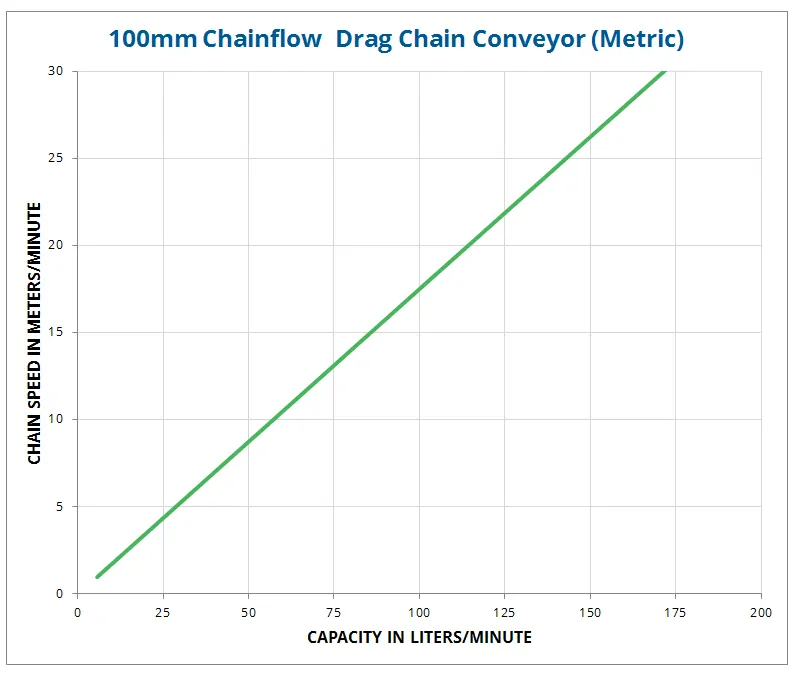

CAPACITY & SELECTION

Chainflow Tubular Drag Conveyors can operate at rates up to 100 ft/min (30m/min) depending on material characteristics & layout. Capacities are typically up to 6.2 ft3/min (176 lpm)

The capacity charts below allow you to roughly estimate the size of the conveyor and the speed based on the throughput requirements in cubic feet/minute (cubic liters/min). The horizontal lines represent the velocity at which your product will pass through the conveyor. The vertical lines indicate the volumetric throughput rate in liters per minute. The diagonal lines are the sizes of the conveyors available.

But don’t think you have to figure out which conveyor will work best for your application. Our sales engineers can do that for you!

Tubular Drag Conveyor Capacity Charts

- Based on your material’s bulk density, calculate the required conveying rate in feet/minute or liters/minute. Locate the amount required on the horizontal scale.

- Move up the vertical line and note where it intersects with one or more diagonal lines. Each intersection point indicates a possible conveyor size.

- From each intersection point, move left horizontally all the way to the vertical scale, indicating the conveyor cable speed.

There are many factors that enter into the tubular conveyor selection process. Beyond the mechanical selection described above, we carefully consider the physical characteristics of the material to be conveyed and the equipment duty cycle.

Tubular Drag Conveyor Selection Guidelines

- The Chainflow conveyor can operate at speeds up to 100 ft/min (30m/min).

- It is generally advisable to apply a larger conveyor at a slower speed if your material has sluggish flow characteristics, is sticky, abrasive or if the equipment operational duty cycle is extensive.

- Smaller conveyor sizes and faster speeds are usually selected when the material is free-flowing and non-abrasive and/or the equipment duty cycle is low.

- Future capacity requirements should be considered. It may be prudent to install a larger conveyor now at a lower speed. You can increase the speed later to accommodate a higher capacity. This can be done with the use of a variable frequency drive or gearing change.

- Surges and uneven feed conditions should be considered. Surge hoppers may provide more constant feeding and may enable the use of a smaller conveyor.