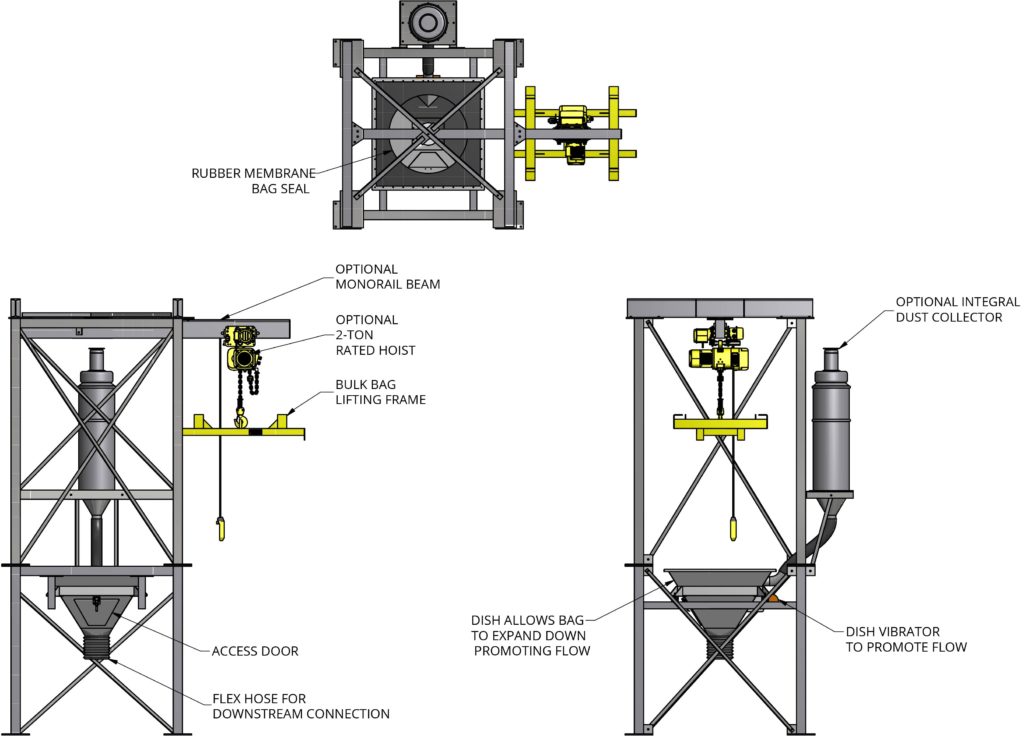

Flo Series Bulk Bag Unloader

System OVerview

The Flo Series Bulk Bag Unloaders include the Flo 40, Flo 60, and Iso Flo models. Each features a sloped hopper equipped with pulse vibration technology.

These designs from the Flo Series can be integrated with various features of our T2 (volume unloading), T3 (loss-in-weight), T4 (single trip bags), and T6 (integral hoist) unloaders. They allow them to fulfill the specific requirements of your applications.

Features of Flo Series Bulk Bag Unloader

Flo Series Bulk Bag Unloaders are designed to enhance the efficiency and safety of bulk bag unloading. Here’s how our innovative design elements can meet the needs of your applications:

- The Flo 40 features a hopper angled at 40 degrees, optimized for the efficient handling of pellets, granules, flakes, and certain powders.

- The Flo 60 incorporates a 60-degree angled hopper, ideal for materials that flow poorly.

- The Iso Flo is equipped with a sealed chamber to allow complete dust containment during unloading.

FLO 40

The Flo 40 bulk bag unloader efficiently and cost-effectively discharges a variety of ingredients from any bulk bag. It works well with ingredients ranging from easy to moderately flowing, including pellets, granules, flakes, and certain powders. It can handle lined and unlined bags, whether they have outlet spouts or porthole outlets.

The Flo 40’s design includes a 40° angled hopper which transforms the square shape of a bulk bag into a cone or silo shape, combined with pulsed vibration to ensure thorough emptying of the bag’s contents. The Flo 40 bulk bag unloader provides a simple and cost-effective solution to emptying bulk bags.

• Easy to moderate flowing pellets, granules, flakes

and some powders

• Lined or unlined with outlet spout

• Lined with porthole in outer bag

• Low investment

• Ingredient easy to moderate flowing

FLO 60

The Flo 60 bulk bag unloader is designed to unload materials with poor flow characteristics from bulk bags while ensuring exceptional dust control. This unloader can manage both lined and unlined bulk bags equipped with outlet spouts, porthole outlets, or even flat bottoms.

Vibration mounted to the unloading hopper works to break up material and move it out of the bulk bag. The steeply angled hopper walls funnel material into downstream equipment.

Two dust vents on the Flo 60 creates a negative pressure zone inside its hopper. This is complemented by a dust membrane made of gum rubber or nitrile that adheres tightly to the sides of the bulk bag. Together, these attributes allows the Flo 60 to achieve superior dust control without the need for an outlet clamping mechanism.

• All ingredients, including poor flowing ones

• Granules, pellets, powders, and fibers

• Lined or unlined, with outlet spout

• Unlined, with plain bottom

• Lined, with porthole in outer bag

• Difficult flowing or compacted ingredients

• Dusty ingredient

• Any bulk bag configuration

ISO FLO

The Iso Flo bulk bag unloader provides total dust containment for unloading any material from bulk bags.

Iso Flo bulk bag unloaders feature the patented Flo Super Clean liner and outlet spout clamping system enclosed in an isolation chamber. The clamp system seals the bag outlet. The isolation chamber draws away dust that may be created as the bag is rigged or removed. This combination of technologies provides total containment of airborne particles at each stage of the bulk bag unloading process.

The Iso Flo features a sloped hopper to safely hold and shape the bulk bag to promote flow. Pulsed vibration ensures that any ingredient will be easily discharged. The Iso Flo comes with either a 40 or 60-degree sloped hopper depending on how much flow inducement is required to maintain a flood feed condition at the bag outlet.

Components of the Flo Series