If you wish to be the leader in the industry of snack foods – convey fragile material properly. The conveying process presents unique challenges that require innovative conveyor technologies. Our conveyor solutions are specifically designed to handle these sensitive products, minimizing breakage and maintaining product integrity during the transportation process. With Spiroflow’s expertise, snack manufacturers can achieve efficiency without sacrificing quality.

Snack Foods – Convey Fragile Material Without Damage

Product damage caused by the transport of friable materials during processing is a huge and costly concern for manufacturers of many kinds of food, industrial, and consumer products. Spiroflow has answered the call with its versatile line of enclosed cable and disc conveyor systems.

Proven to gently convey more than 900 different types of products, including coffee, cereal, nuts, beans, and pet food, Spiroflow’s tubular drag cable conveyor systems offer a reliable method for conveying food and industrial products with virtually no product separation or degradation.

We offer three volume-sized series of enclosed cable and disc conveyor systems that can be configured in multiple custom layouts to fit your plant configuration and specific material handling needs. Our tubular drag conveyor systems are used by Fortune 500 companies and top-tier food processors globally, as well as a host of industrial businesses.

The Best Conveyors for Gentle Handling of Snack Foods

Snack foods such as pretzels, nuts, and others can be challenging products to convey. Most snack foods are very delicate and must be kept in their original shape at the end of the conveying process. With many plants conveying more than one line of snacks, the conveyor must be versatile enough to handle different products. Let’s take a look at some of the commonly used types of industrial conveyor systems for snack food processing.

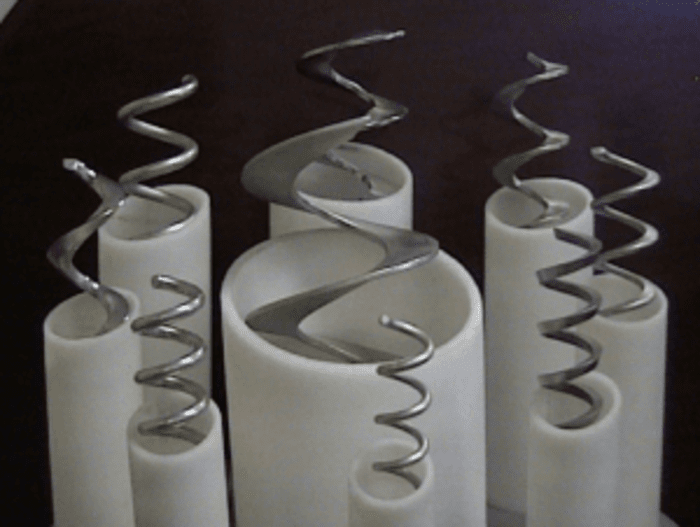

Flexible Screw Conveyors

Our flexible screw conveyor is made up of one moving part – the spiral inside a tube. As a result, the flexible screw conveyor is a very versatile and low-cost conveyor. The spiral in the system continually mixes the blend as it conveys using the helical motion, allowing you to maintain the batch integrity of the flavors as you convey. It is ideal for conveying blends of snack foods such as mixed nuts as it is easily cleaned using the quick-release flanges. This allows you to have a fast turnaround between flavor batches.

Aero Mechanical Conveyors

By creating an airstream, the aero mechanical conveyor moves the product up the tubes along with high-speed discs and a rope. This type of conveyor is a great choice for conveying snack foods as it offers total containment. So, any dust created from the snack foods will be contained within the system. This reduces the risk of explosions caused by static build-up on the combustible dust. This airtight conveyor runs quietly and with minimal energy, making it an excellent choice for conveying snack foods such as pretzels and nuts.

Cable Drag Conveyors

The cable drag conveyor operates in a similar way to the aero mechanical conveyor, as it has evenly spaced discs connected by a rope. However, it drags the product along the tube rather than creating an airstream. If you are conveying fragile snack foods, this is an excellent choice, as it is extremely gentle at conveying friable products and will reduce degradation on your product. As the system does not use vacuums, air blasts, conveyor belts, or buckets, this would be the best choice if minimizing the degradation of your product is of top priority.

Spiroflow Can Provide Spare Parts for Your Industrial Conveyor Systems

We have a dedicated after-sales department that ensures rapid assistance with your needs for spare and replacement parts, dispatching ex-stock items within 24 hours. For products encountering abrasive materials, we advise keeping essential replacement parts readily available. Abrasive materials often lead to accelerated wear and tear, necessitating more frequent replacements.

Our team is always happy to recommend the most critical components to keep in your inventory, ensuring minimal downtime and maintaining operational efficiency. We aim to support your production with reliable access to necessary parts, providing peace of mind and helping to prevent unexpected disruptions in your processes.

Are You Looking to Improve the Conveying Process in Your Facility? Reach Out to Spiroflow

Are you seeking to enhance the conveying process within your facility? Look no further and reach out to Spiroflow. Whether you’re in the market for an efficient tubular drag conveyor, a reliable cable conveyor, or another type of gentle handling conveying system suitable for your delicate snack foods, our team is ready to assist. With more than 45 years of expertise in the solids and bulk handling industry, Spiroflow stands at the forefront of providing top-notch conveyor solutions.

We boast the broadest range of conveyor technologies, designed to meet a variety of needs, ensuring we can tackle any conveying challenge you face. Our commitment to innovation, quality, and customer satisfaction has made us a trusted partner in optimizing production processes. Contact us to discover how our team of conveyor manufacturers can contribute to the success of your operation, enhancing efficiency and protecting the integrity of your products every step of the way.

FAQ

What Makes Spiroflow Conveyors Ideal for Snack Foods?

Spiroflow’s conveyor solutions are tailored to handle the delicate nature of snack foods, ensuring minimal breakage and preserving product integrity. With technology designed for gentle handling, our conveyors are perfect for snacks that need to maintain shape and quality throughout the conveying process.

How Do Spiroflow Conveyors Handle Different Types of Snack Foods?

Our conveyors are versatile and capable of handling over 900 product types, including coffee, cereal, and nuts. With systems like the flexible screw conveyor, aero mechanical conveyors, and cable drag conveyors, we offer solutions that mix, contain, or gently drag products, accommodating various snack food processing requirements.

Can Spiroflow’s Conveyors Reduce Product Degradation?

Our cable drag conveyors are specifically designed to convey fragile snack foods gently, reducing product degradation significantly. This makes them an excellent choice for ensuring that friable products are conveyed with utmost care.

What After-Sales Support Does Spiroflow Provide?

Spiroflow offers a dedicated after-sales department for rapid assistance with spare and replacement parts, ensuring ex-stock items are dispatched within 24 hours. We also recommend keeping essential parts in stock for products encountering abrasive materials to minimize downtime and maintain efficiency.

How Can Spiroflow Improve My Facility’s Conveying Process?

With over 45 years of industry expertise, Spiroflow can enhance your facility’s conveying process with a range of efficient and reliable systems suitable for delicate snack foods. Our commitment to innovation and customer satisfaction means we provide solutions that enhance efficiency and protect product integrity, tailored to meet your specific needs.