A cable drag conveyor can be the perfect fit for your process, but how much does a cable drag conveyor cost? Our sales team hears this question every day. The price of a tubular drag conveyor varies depending on the selected options, materials, and layout, as well as your desired capacity and conveying rate.

Here at Spiroflow, we’ve been in the bulk material handling industry for more than four decades. We want to share our years of experience through this blog. This article will describe all of the factors that go into determining the cost of a cable drag conveyor. Hopefully, this article will help you find the best conveyor for your process.

What is a Tubular Cable Drag Conveyor?

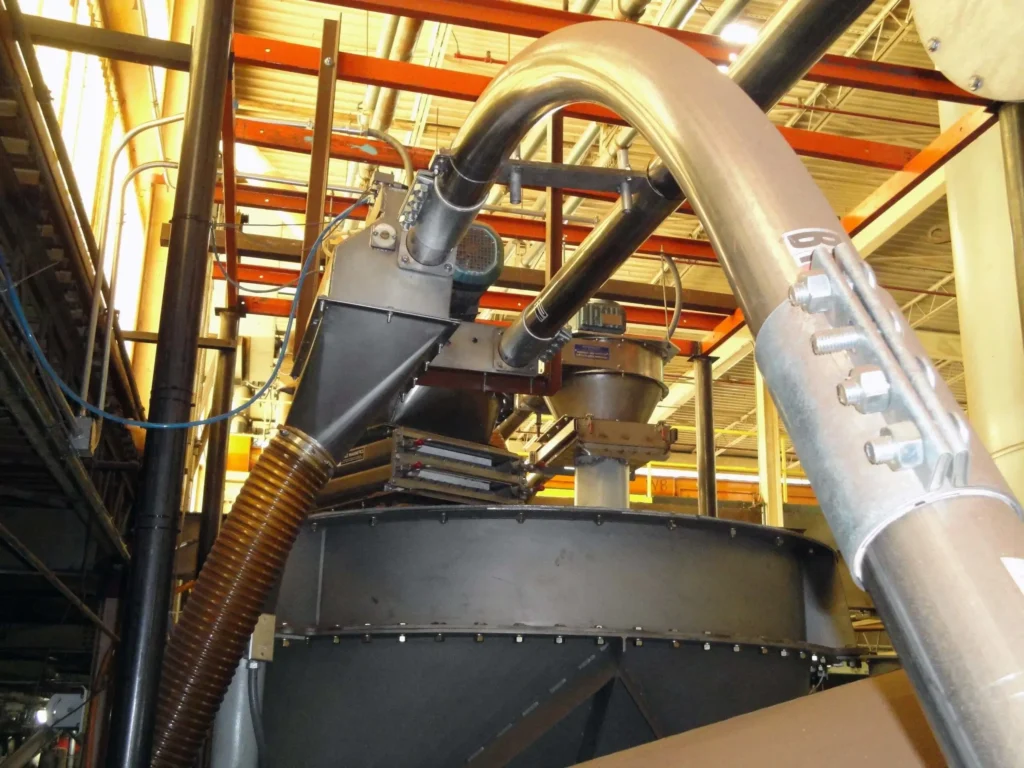

A tubular cable drag conveyor is a mechanically driven conveyor that drags material along the inside of a completely enclosed tube. It uses a cable and disc assembly to drag a variety of materials. The conveyor can have multiple in-feed points and discharge points. These types of conveyors have been used throughout a range of industries for more than 50 years.

How Is a Cable Drag Conveyor Constructed

The objective of every belt conveyor system manufacturer is to create a machine that precisely meets your specific requirements. While the fundamental operation of conveyors remains largely consistent, the differences in their construction set them apart. These variations in design and build are the main factors that influence the cost. Take, for example, Spiroflow cable drag conveyors. They are capable of handling a total circuit length of up to 400 feet (120 meters). Additionally, for longer distances, multiple conveyors can be interconnected.

Cable Drag Speed and Capacity

Manufacturers typically construct cable drag conveyors with different tube sizes. At Spiroflow, we offer three models based on tube diameter. Check out the capacity chart below to understand what conveyors of different sizes can do.

Standard Construction and Components

To understand the reliability and efficiency of Spiroflow cable drag conveyors, it’s essential to delve into their standard construction and components. These conveyors are built using high-quality materials and components, each contributing to their robust performance and longevity. Below is a breakdown of the key elements:

- Tubes – Made of 304 stainless steel, known for its durability and resistance to corrosion.

- Cable – Also constructed with 304 stainless steel, ensuring strength and longevity.

- Discs – Use UHMWPE (Ultra High Molecular Weight Polyethylene) for smooth operation and wear resistance.

- Drive assembly – A critical component that powers the conveyor system.

- Automatic cable tensioner – Maintains optimal tension in the cable, crucial for consistent performance.

- Sweeps – Designed at standard angles of 90˚ for efficient direction changes in the conveyor path.

Optional Features

This is where the final price of a cable drag conveyor can really be impacted. Cable drag conveyors can be designed with several options to increase the production of your process. The options range from construction materials to cleanability choices. A full list of possible add-ons, from a Spiroflow perspective, is below:

- Tubes – Constructed from 316 stainless steel, known for its enhanced corrosion resistance and suitability for sanitary applications.

- Chain – Also made from 316 stainless steel, ensuring durability and longevity.

- Sanitary finish – Designed to meet high hygiene standards.

- Support base at the inlet – Provides stable support for the conveyor inlets.

- Corner sprockets (90° Idler Housing) – Facilitates smooth turns in the conveyor system.

- Access covers with hinges – For easy maintenance and inspection.

- Pull-out inlet chute access panels – Allows quick access for maintenance or adjustments.

- Inlet vibration – Assists in material flow and prevents blockages.

- Outlets and inlets installed on tubes – Offers flexibility in system layout.

- A pneumatically operated inline discharge valve (a tube valve with a chute) – Enables controlled material discharge.

- Increased capacity chute (splash guard, dust hood, lid) – Enhances capacity and minimizes spillage and dust.

- Pneumatic or manual inlet baffle – Regulates material flow into the conveyor.

- Rotation sensor – Monitors and ensures consistent operation.

- Air purge – Protects internal components from dust and debris.

- Chain vibrator – Aids in material flow, especially for difficult-to-move substances.

- NEMA 4 or 7 level probes – Ensures precise material level management.

- Mobile base – Adds mobility for versatile placement.

- Controls (included or not in the VFD) – Offers operational control, with options for Variable Frequency Drive.

- Wash gate and drain – Facilitates easy cleaning and drainage.

- Sight glass – Allows visual inspection of the conveyor contents.

- XP switch – An explosion-proof switch for hazardous environments.

- Static grounding – Prevents static build-up, enhancing safety.

- 90° sweeps – Enables right-angle turns in the conveyor path.

- Sweeps at custom angles – Customized for specific layout needs.

Additional Costs with Cable Drag Conveyors

I would consider installation and maintenance costs for cable drag conveyors as moderate. The cable must be tensioned periodically and replaced every 2,000 to 6,000 hours of operation. Making sure the cable is tensioned properly is absolutely critical. Over-tensioning the cable will cause a failure. Using an auto-tensioning system will make an operator’s life much easier and will save you money.

The work to install a cable drag conveyor can greatly vary depending on the manufacturer. Some manufacturers supply the conveyor belt system components, which must be completely assembled on-site by the customer. At Spiroflow, we complete partial assembly in our factory before it is shipped out. This can save you a lot of time and money. Be sure to understand the work involved in installing your conveyor and consider any on-site assembly costs in the total cost of the conveyor. A cable drag conveyor’s energy consumption is low compared to other mechanical conveyor belt solutions. Its motor doesn’t require the same power draw compared to more heavy-duty conveyor belts.

How Much Does a Cable Drag Conveyor Cost?

When considering the investment in a cable drag conveyor, one of the most frequently asked questions pertains to its cost. The answer, however, is not straightforward as it varies significantly based on the conveyor’s configuration, length, and additional features. For a basic model with a short run, you can expect to spend around $20,000 (£16,600). This price typically includes the standard construction with essential components, suitable for basic operations and shorter distances.

On the other hand, a more sophisticated model equipped with a full range of features and options can cost up to $90,000 (£75,000). This higher price tag reflects the inclusion of advanced components such as specialized materials for the tubes and chains, custom angles for sweeps, additional safety features like static grounding and explosion-proof switches, as well as enhanced control systems with variable frequency drives.

Therefore, when budgeting for a cable drag conveyor, it’s crucial to consider both the basic operational requirements and any additional features that may be necessary for your specific application. The final cost will be a balance between these requirements and the available budget.

Do You Have More Questions?

As I mentioned at the top of the article, we’ve been in the bulk material handling industry for more than 45 years. Our team members have seen it all and are happy to help with any questions you might have. If you’re interested in more than just cable drag conveyor technologies, feel free to view our entire line of conveying solutions. Spiroflow is also an industry leader in control systems integration.Interested in exploring beyond cable drag conveyor belt systems? Discover our full range of conveyor solutions. As an industry leader among belt conveyor manufacturers in control systems integration, Spiroflow is here to elevate your operations. Contact us today to find out how we can support your specific needs.