Cable drag conveyor problems can impede material flow, disrupting operations and causing costly delays. Overcoming these challenges is essential for keeping material moving smoothly along the line. Discover effective solutions to mitigate problems with cable drag conveyor solutions and ensure uninterrupted material transport in your production facility.

Why Is It Important to Learn About Cable Drag Conveyor Problems?

What are the most common problems with cable drag conveyors? We know why you’re interested in understanding all the possible issues that can come with these conveyor technologies. Adding a cable drag conveyor to your facility is an investment. You want to make sure you get the most out of this machine. We can assure you that these conveyors deliver exactly what they promise when run properly.

That’s what this article is all about – how to avoid common problems and mistakes. Here at Spiroflow, we’ve been in the bulk material handling industry for more than 45 years. Our team has designed and engineered thousands of conveyor solutions all over the planet. It’s been our goal since day one to provide quality industrial conveyor systems and help educate our customers.

What Cable Drag Conveyor Technologies Do?

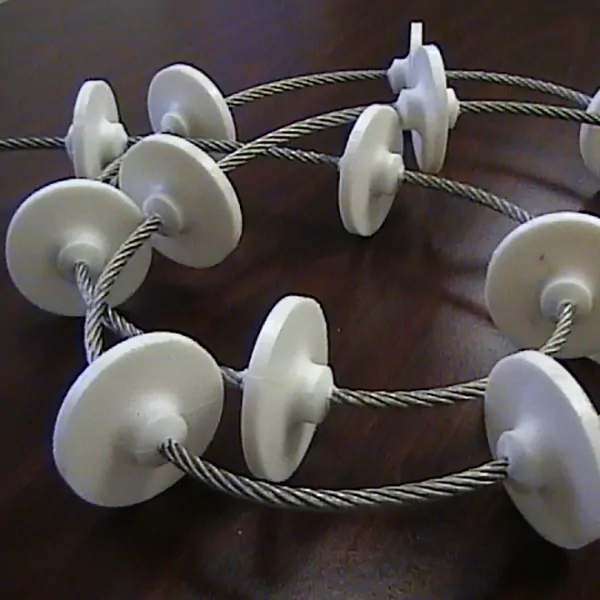

A tubular cable drag conveyor uses a cable and disc assembly to drag material inside a totally enclosed tube. This conveyor choice can be designed to have multiple inlets and outlets. Material can be streamed or meter-fed into the system.

More specifically, a motor-driven sprocket within the tube pulls the cable and disc assembly in a continuous loop through the circuit. This system can operate within multiple planes, which provides great layout flexibility. If one isn’t enough, several conveyors can be linked together to cover greater distances.

How to Avoid Cable Drag Conveyor Problems?

Do you want to ensure your cable drag conveyors are delivering the rate your process needs? Do you want to avoid spending a fortune on maintenance and replacement parts? Do you want to shorten system downtime? If these are your goals for a production process or you just want to know how to get the most out of your cable drag conveyors, the solutions are right here.

There’s nothing inherently flawed or faulty with tubular drag conveyors. Issues generally arise due to operator mistakes, and these are easy to fix or avoid. All you need to do is keep the following information in mind:

- Every part of the circuit must be dent-free.

- All internal moving parts must be in alignment with the exit and entry points.

- It is helpful to utilize available options that provide system feedback (level sensors, rotation sensors, and tension position indicators).

Be Mindful of Which Material You’re Conveying

Make sure the material you are conveying is appropriate for this type of conveyor. Anything abrasive, hygroscopic, cohesive, or slurry should stay out of a cable drag. Utilize a test lab if you have any questions or concerns about what should be conveyed.

Another tip you need to keep in mind – do not overfeed the conveyor. Trying to max out the capacity of a tubular cable drag conveyor may be tempting, but it can put too much strain on its components. If you find yourself overfeeding a cable drag, you should consider a larger or different type of conveying system. An experienced supplier like Spiroflow will make sure you get the right type and size of the conveyor to meet all of your application parameters.

Keep Your Conveyors Running Smoothly

The conveyor circuit must be supported with the included brackets to prevent circuit deflection during operation. The circuit is not self-supporting so special care must be taken where changes in direction occur. This is normally achieved using bent tubes. In these areas, there’s more internal force present to change the direction of the conveyor path.

The circuit is constructed from multiple tube sections of varying lengths. These are joined with sleeved clamps at the joints between each section. It is very important that the joints are in alignment with the mating section and form a continuous, uninterrupted circuit. The connection between circuit members must be flush without any burrs produced during cutting. This is critical for correct operation.

The Importance of Maintaining Proper Tension

To keep the cable and disc engaged on the drive and idler sprockets, it is necessary to keep them tight. We always recommend using a tensioning device that applies a constant force to the system to ensure the discs engage correctly onto the sprockets. The applied force from the tensioner is variable depending on the circuit layout, length, and the material being conveyed. It is necessary to adjust this during commissioning to achieve optimal system performance.

Have Any More Questions? Spiroflow Is Here for All Your Conveying Needs

Help is a phone call away. Our teams in the United States or the United Kingdom are always willing to answer any questions you may have. Here at Spiroflow, we offer a wide variety of mechanical conveyors to choose from if a cable drag conveyor isn’t right for your process. We also design and supply bulk bag dischargers and fillers. If you’re interested in control systems integration, we do that as well. Be sure to contact us and we’ll help you improve your conveying process to ensure maximum efficiency at your production facility.

FAQ

Why Is It Important to Learn About Cable Drag Conveyor Problems?

Understanding cable drag conveyor problems is crucial because these issues can disrupt operations, causing costly delays. By learning about these challenges, you can implement effective strategies to keep material moving smoothly along the conveyor line, ensuring uninterrupted production.

What Cable Drag Conveyor Technologies Do?

A tubular cable drag conveyor employs a cable and disc assembly to drag materials inside an enclosed tube. This conveyor type can feature multiple inlets and outlets, allowing for versatile material feeding options. Its motor-driven sprocket pulls the cable and disc assembly through the circuit, enabling operation within various planes and layout flexibility.

How to Avoid Cable Drag Conveyor Problems?

To prevent cable drag conveyor problems, ensure every part of the circuit is dent-free, all internal moving parts are aligned with entry and exit points, and utilize system feedback options like level sensors and rotation sensors. Choose suitable materials for conveying, avoid overfeeding, properly support the conveyor circuit, and maintain proper tension on the cable and disc assembly.

How Can I Address Cable Drag Conveyor Problems Efficiently?

To address cable drag conveyor problems efficiently, start by identifying the specific issues causing disruptions in material flow. Implement proactive maintenance schedules to address cable wear and tension problems. Utilize system feedback options such as level sensors and rotation sensors to monitor conveyor performance. Additionally, ensure proper material selection and feeding practices to prevent issues.

What Are the Benefits of Using Cable Drag Conveyors?

Cable drag conveyors offer several benefits, including gentle material handling, enclosed design for dust containment, and flexibility in layout and configuration. They can handle a wide range of materials and are suitable for various industries such as food processing, pharmaceuticals, and chemicals. Additionally, their low maintenance requirements and energy efficiency make them a cost-effective choice for material transport.