Customer Requirements

Excelso Coffee & Tea needed a reliable means of transferring blends of roasted coffee from a mixer where flavoring is added to a buffer hopper above the packaging machine that packs finished product for shipment to customers.

For 14 years, Excelso Coffee & Tea Company in Norcross, Georgia, has been using a Spiroflow Aero Mechanical Conveyor (AMC) in its flavored coffee production operation without replacing any parts – until July 2008. Excelso is a custom provider of coffee and condiments to offices, vending machine outlets and private label sales.

1)It roasts more than 2,000,000 lb/ 907,000kg of coffee a year.

2)This equates to 3,000,000 cups of coffee a day.

3)The Model PC3 Aero Mechanical Conveyor was manufactured and installed at Excelso’s production facility in 1994.

4) Operating intermittently eight hours a day, five days a week, the AMC conveys coffee from a V-Ribbon blender to a storage hopper for packaging into pouches or bags.

It was the first time they needed a replacement wire cable in 14 years. Normally, we expect cables to be replaced every five to seven years depending on the application. What’s equally phenomenal is the fact that no other replacement part has been required for this machine.

“We selected Spiroflow because of their experience and excellent after sales support. We also needed a totally enclosed system that is dust free and wouldn’t alter the integrity of the flavored coffee. The AMC seemed to be a perfect fit.” – Allan Shaw, Vice President of Excelso Coffee & Tea.

Spiroflow Solution

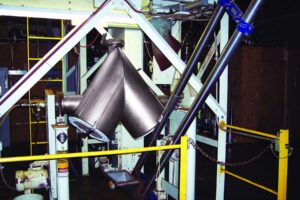

Spiroflow’s PC3 Aero Mechanical Conveyor plays a critical role at Excelso in conveying coffee from the V-blender to a hopper for storage and eventual packaging.

– AMCs are one of the most efficient methods of conveying materials such as coffee because of their gentle dust-free and clean handling properties.

– Constructed of stainless steel to reduce flavor cross-contamination from the previous batch, the AMC can be washed with water or other cleaning solution through a valve at the top outlet and a drain on the bottom.

– The PC3 AMC was specifically designed to meet Excelso’s exact hygiene requirements.

“We provide our customers with the highest quality coffee at the best possible price while delivering excellent service,” noted Shaw. “To do this, we operate a facility where only the best equipment is used, the most modern procedures are followed and where quality control is number one. The AMC is a dust-tight, well-designed system that is virtually self-cleaning.”

He further commented, “We have been extremely pleased with its performance in getting the flavored coffee to the storage hopper for final packaging in the quantities customers require.”