Are you still relying on forklift trucks to transport products across your premises and wondering if there is a better way to move the material? It might be time to consider advanced conveyor technologies as a superior alternative. When it comes down to comparing conveyors vs. forklift trucks – here’s how you can make a strategic decision that affects your operation’s safety, efficiency, and cost-effectiveness.

Conveyors vs. Forklift Trucks – Revolutionizing Material Movement in Your Business

The forklift truck is a common sight in factories. It’s an efficient and low-cost method for moving bulk bags across the factory floor. However, the risks associated with forklift use – including equipment damage, product loss, and the potential for injuries – can lead to unforeseen expenses. Human error, a significant factor in workplace hazards, further diminishes their cost-effectiveness.

Conveyor Belt Systems Come With Their Fair Share of Advantages

Unlike their human-operated counterparts, conveyor solutions offer a reliable and efficient way of moving products. Here are some of the key benefits:

- Conveyor belts streamline the movement of materials, significantly reducing handling times and improving overall productivity,

- Over time, they can lower operational costs by minimizing product damage during transit,

- With a wide range of types and configurations, conveyor belt solutions can handle a variety of materials, from bulk goods to fragile products,

- They can be expanded or reconfigured to accommodate changing operational needs or increased production demands,

- They provide a consistent method of transport, ensuring that materials are moved gently and efficiently, reducing the chance of damage.

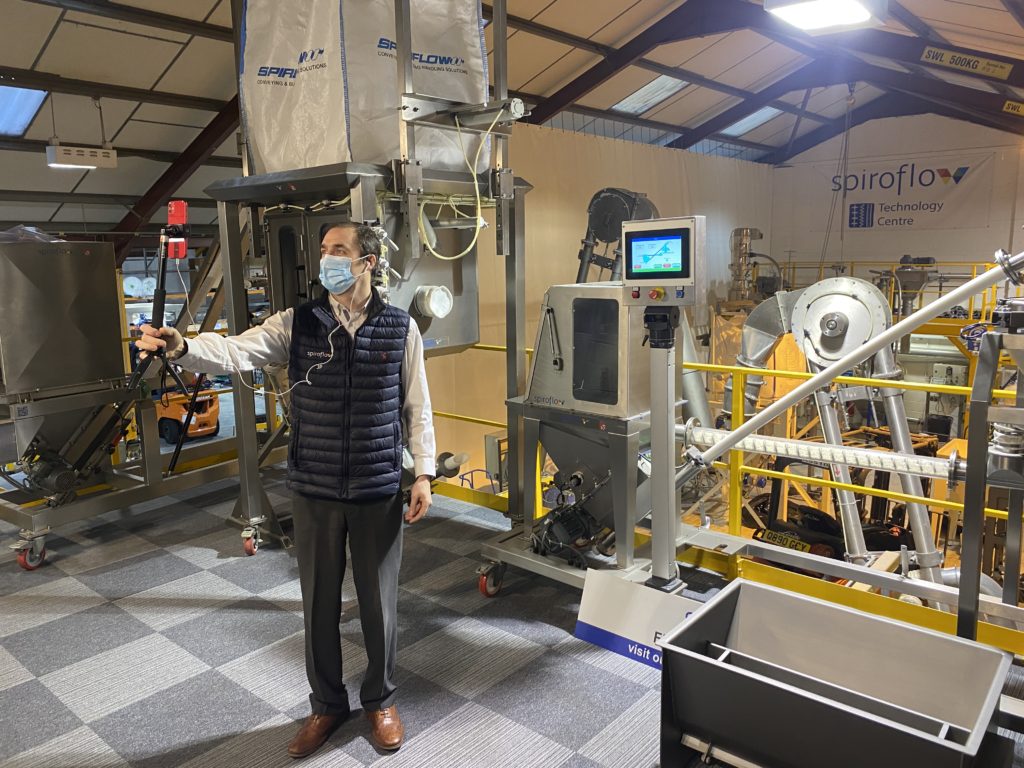

Conveyors don’t call in sick or arrive late, ensuring continuous productivity. They also handle materials gently and hygienically, enhancing overall productivity and safety. At Spiroflow, we boast an extensive range of advanced industrial conveyor systems, offering more than just a one-size-fits-all approach.

Tailored Solutions and Product Testing

We understand that each material handling challenge is unique. That’s why we don’t just sell conveyor systems – we provide solutions that are customized to your specific needs.

All testing at Spiroflow is free of charge and conducted by our team of expert engineers. This service is available to both new and existing customers, aiming to replicate your operational conditions as closely as possible. After material testing, we provide a detailed report to ensure the belt conveyor system we propose is perfectly suited to your requirements.

Spiroflow’s Conveyor Belt Solutions

At Spiroflow, we understand that each material handling challenge is as unique as the businesses we serve. That’s why we’re proud to be one of the conveyor systems manufacturers with the most extensive range of solutions designed to meet the diverse needs of our clients. Here are our best options:

Flexible Screw Conveyors (FSC)

The flexible screw conveyor uses a spiral inside a tube to convey the product up the tube and even around corners. Ideal for a variety of materials, FSCs are particularly effective for continuous blending, with a design that allows easy cleaning and maintenance.

FSCs can be stripped down in a few minutes and usually have an optional quick release and hygienic fitting to aid cleaning. The screw can be removed from the tube so smooth surfaces can be cleaned and visually inspected. All in all, they are an excellent choice for businesses seeking a cost-effective, dust-free solution for their conveying needs.

Aeromechanical Conveyors

This conveyor system operates with evenly spaced discs traveling at speed, which creates an air stream to convey the product along with the discs. This process is perfect for fragile materials like coffee beans and powders, as it minimizes damage and is completely dust-free. Its stainless steel construction is also pretty easy to clean and reduces flavor cross-contamination if it is used for different batches of material.

Tubular Drag Conveyors

Tubular conveyor belt systems come in two main types, depending on what they use to operate. The first one utilizes cable and discs, dragging the product along inside a tube. It’s an excellent choice for conveying fragile materials without damage. It’s also highly hygienic, easy to clean, and offers a completely enclosed system. With our rope tensioner or DART, the cable life can be extended, thus reducing maintenance costs in the long run.

There are also chain and disc tubular drag conveyors that operate in a similar way but utilize a heavy-duty chain. For hazardous materials or outdoor applications requiring robust solutions, this conveyor type offers durability and safety, ensuring efficient material handling under challenging conditions.

Contact Our Team at Spiroflow to Learn More

Don’t let manual handling slow you down or put your team at risk. If you’re ready to transform your material handling processes with one of the best belt conveyor manufacturers in the game, contact us today. Our team is ready to guide you in selecting the perfect solution, ensuring it aligns with your specific requirements and industry standards.