A tubular drag chain conveyor plays a crucial role in various processes. When faced with drag chain conveyor problems, whether they’re running inefficiently or not at all, it significantly hampers productivity. At Spiroflow, we’ve been in the dry bulk material handling industry for more than 45 years and we are proud of our work and our conveyors. We want our conveyors to run well, just like you do. That’s why we are writing about keeping your conveyors moving.

What is a Tubular Drag Chain Conveyor?

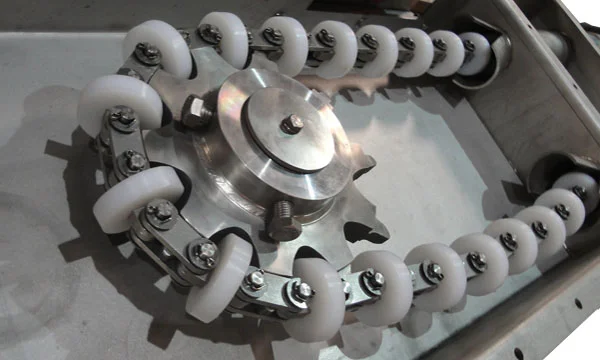

In this article, the term “drag chains” refers to heavy-duty tubular drag chain conveyors. These specific conveyors feature crevice-free stainless steel chains and UHMWPE disc assemblies operating within a stainless steel tube. Their enclosed design ensures a dust-free environment while accommodating multiple inlets and outlets and offering flexibility in conveying rates.

Between the standard tubular drag chain conveyors and their ultra-heavy structural counterparts lies a notable distinction in design and application. While both operate with the efficiency and dust-free benefits inherent to enclosed systems, the choice between these offers a robust solution for more demanding environments.

This adaptability allows for a broader range of materials to be handled, providing a tailored approach to meet specific industry needs. The decision between these two types hinges on assessing the operational demands, material characteristics, and desired throughput rates.

Also, ultra-heavy structural tubular drag chain conveyors are mentioned in this post. They are characterized by chain and disc assemblies made from either steel or cast iron, housed within a structural pipe. The intricacies of these conveyors will be explored in further detail in a separate post covering drag conveyor cost. However, the current focus remains on the intricacies and functionality of tubular drag chain conveyors.

How to Avoid Drag Chain Conveyor Problems

Any problems with tubular drag chain conveyors can be avoided. Issues sometimes arise when users expect ultra-heavy-duty results from this heavy-duty conveyor. We believe tubular drag chain conveyors are effective pieces of machinery, and it is our job to inform and advise processors of the right conveyor for their application.

Ultra-heavy-duty drag chain conveyors operate within the confines of a structural schedule of 40 pipes. Tubular heavy-duty drag chains operate within a stainless steel tube that is not structural.

Like many conveyors, they must be properly supported and operated correctly to avoid damage from overloading or misuse. The conveyor circuit defined by the outer casing also has to be considered for strength and wear characteristics. The tube is not as strong as a pipe.

The bottom line is that you can’t treat a tubular drag chain conveyor as an alternative to a structural drag chain conveyor. Tubular conveyors will be cheaper, but the conveyors are designed for different applications.

The Value of Investing in Quality Conveyor Chains

One of the biggest benefits of drag chain conveyors is their hygienic quality. Processors in the food industry lean towards these because particles won’t get trapped in the chain and disc assembly. Both structural and tubular conveyors effectively maintain blends.

They both work well with dry, fragile, and abrasive products. Drag chain conveyors offer a multitude of advantages for efficient material handling, including:

- They can operate in three planes, allowing complex circuits and eliminating points of transfer and using only a single drive.

- They have minimum horsepower and energy consumption when compared to pneumatic conveying systems with equivalent rates.

- They can be flood or meter-fed.

- They have minimal noise levels.

- There’s no need to mechanically separate the product from the conveying stream. Gravity works just fine!

- The gentle conveying action minimizes product degradation.

- They won’t separate blends.

- They may operate under pressure differential or inert purge.

Tailoring Conveyor Technologies Through Precision Testing

Navigating the complexities of material handling requires a nuanced understanding of your specific needs and the challenges your materials present. At Spiroflow, we will ensure that our conveying solutions meet these unique requirements. Let’s see what these tests had to say.

The Value of a Test Lab in Optimizing Conveyor Efficiency

Spiroflow, one of the leading conveyor manufacturers, knows how important your application is to you. We work closely with our clients to ensure our recommended conveying solution meets or exceeds all of your requirements.

That’s where our test labs in the US and the UK come into the picture. They are designed to test your materials under actual operating conditions. Material testing is particularly important if your product is hygroscopic, moist, cohesive, hot (up to 180˚F/82˚C), sludge, slurry, or has fine particles.

Selecting Optimal Materials for Conveyor Durability

What you want inside the conveyor determines what its contact surfaces should be made of. Based on your application needs our tubular drag chain conveyor can be supplied in 304 or 316 stainless steel. Non-contact component materials of construction can be 304 or 316 stainless steel.

Ensure Smooth Operations With Chain Maintenance

Tubular drag chain conveyors earn their heavy-duty moniker. They require periodic, very low maintenance. They can even run empty or start under load.

The mention of an auto-tensioning system emphasizes the importance of maintaining proper chain tension to reduce manual maintenance and extend its life. Auto-tensioners are standard features that ensure the conveyor operates efficiently and reliably over time, highlighting their design for heavy-duty applications and their operational efficiency.

Elevating Your Material Handling Solutions With Spiroflow

For over 40 years, Spiroflow has been a leader in material handling solutions, offering more than just advanced industrial conveyor systems. Our expertise extends to a comprehensive product lineup and seamless control systems integration, providing top-notch automation solutions tailored to your needs.

Ready to elevate your process efficiency with Spiroflow’s innovative conveyor solutions? Then contact us today with any questions you have. Let us help you take the first step towards optimizing your operations.