In any business, it is important to maximize efficiency to ensure sustainable growth and continuity. Accurate weighing is one area that can often be improved. So, what’s the importance of accurate weighing when filling bulk bags? A slight overfill in one day may not be considered significant. However, if this overfill consistently occurs over a year, you may be giving a significant amount of your product away for free.

The Importance of Accurate Weighing When Filling Bulk Bags

Did you know that you are probably overfilling if you offer goods in bulk bags at a specified weight per bag? This is often done intentionally so that customers are not unintentionally shortchanged. However, do you have any control over how much you give out for free, and are you aware of it? If the answer is NO, then there are several things you can do.

First, ask yourself how much is your average overfill. It could be 10, 15, or 25 lb. (5, 7, or 12 kg), but we’ve also seen extreme overfills of 290 lb. (130kg) over target weight. It is critical that you learn how much over your goal weight you are packing before improvements can be made.

This can be a scary place to start, but be assured that it is not difficult to minimize the average overfill of 2 – 5 lb. (1 – 2 kg). For example, if you reduce your overfill from 10 pounds (4.5 kg) to 2 pounds (900 g), the 8 pounds (3.6 kg) that was left over is paid for and added to the next bag. This simply makes good financial sense. This modest enhancement will be reflected in additional recovered revenue, which directly translates into further profit.

What Are the Next Steps?

Take note of these four key factors to help you rethink and rework your bulk bag weighing system. By doing so, you will improve your weighing accuracy and improve profitability significantly.

1. Consistent Product Flow

Any batch-weighing application’s accuracy increases as the consistency of the product flow rate increases. This refers to the flow rate during a batch and from batch to batch. Bulk bag fillers typically have a weighing algorithm that includes an “in-flight offset” program that ‘learns’ when to stop product flow ahead of reaching the weight target. This is to compensate for a product that is falling between the metering device and the bulk bag. The more consistent the flow, the better the algorithm is able to fine-tune the system.

2. Metering Device

Weighing accuracy is critically dependent on how well-suited the metering device is to the application. A simple, two-position slide gate valve may provide adequate accuracy when filling bulk bags with a reasonably low bulk-density product at a slow rate.

However, when filling a high bulk-density product at a high rate, a belt conveyor system or feeder may be required to achieve the desired accuracy. The ultimate accuracy of a positive displacement type metering device (e.g. screw conveyor, screw feeder, rotary airlock, etc.) is limited to +/- the weight of the product in one flight or pocket. Therefore, high bagging rate applications require great care in selecting the best metering system. A conveyor belt system sized to provide a high flow rate necessary to achieve the desired bagging rate may not be able to produce adequate weighing accuracy because it is too large. In that case, a different metering device, a second dribble feed device, or a surge hopper with a fast-acting slide gate valve may be required.

3. Dead Load

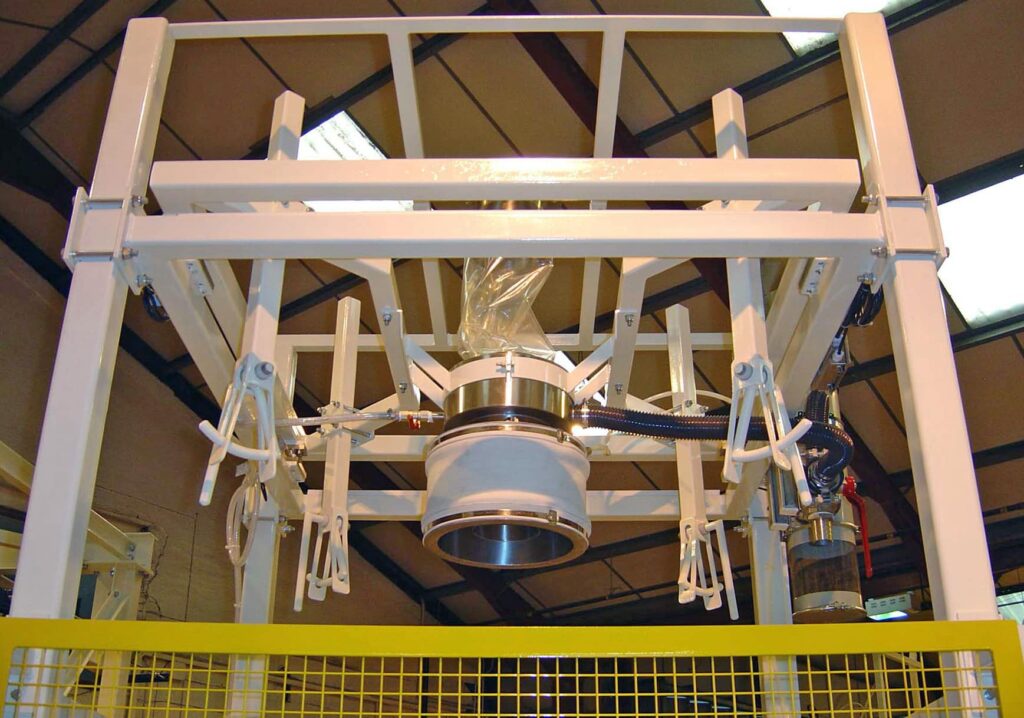

The weight that the weighing system sees before the product is added to the bulk bag is called the dead load. Gross weighing systems – those that weigh the entire bulk bag filler along with the product in the bag – can see a dead load of + 2,000 lb. (+900kg) depending on the filler and its configuration. Bulk bag fillers that use hang weighing see a dead load equal to a few lb. (kg). This means the hang weighing filler can use smaller load cells or that the portion of the load cell span taken up by the dead load is much smaller. Either way, higher weighing resolution and more accurate weighing is the result.

4. Weighing System Minutiae

When filling bulk bags, the specific type of load cell, controller/PLC resolution, scan time, and the like are really not significant factors in achieving weighing accuracy. In our experience, any weight controller and PLC implementation have more than enough resolution to achieve the desired bulk bag weighing accuracy. With this knowledge on improving weighing accuracy, stop giving away free product and start gaining profit on your bottom line.

Seeking Expert Guidance in Bulk Material Handling? We’re Here to Help

If you have any questions or would like advice, please do not hesitate to contact us. We have been in the bulk material handling industry for more than 45 years and are happy to work with you to improve your weighing accuracy. Whether you’re dealing with conveyor belts, conveyor belt solutions, our innovative flexible screw conveyor, or any other aspect of conveyor belt systems, our team is equipped to assist you.Our expertise extends across a wide range of conveyor technologies, including conveyor belt systems and industrial conveyor systems. As leading conveyor solutions providers and conveyor systems manufacturers, we understand the nuances and challenges of efficient material handling. Our goal is to work collaboratively with you, leveraging our experience as conveyor manufacturers and belt conveyor manufacturers, to enhance your weighing accuracy and overall operational efficiency.