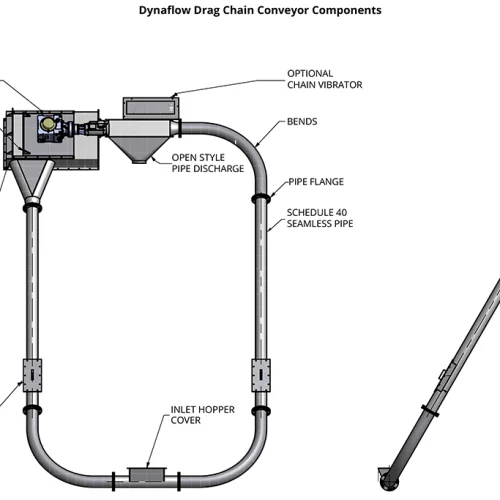

Dynaflow Drag Chain Conveyors

System OVerview

In the world of material handling and industrial automation, the quest for efficiency, reliability, and versatility is ongoing. Our Dynaflow drag chain conveyors are a solution that has emerged as a game-changer in this arena. These conveyor solutions represent a remarkable fusion of engineering innovation and practicality, offering industries a reliable means to transport bulk materials smoothly and seamlessly.

The Dynaflow Tubular Drag Chain Conveyor Is a Mechanical Drag Conveyor System Operating Within the Confines of a Pipe

Spiroflow’s Dynaflow Chain Drag Conveyor utilizes flanged schedule 40 piping with a heavy duty link and pin style chain. Making it an ideal solution for dense, abrasive, or high temperature material (up to 420F/216C) applications.

Dynaflow is a versatile conveyor with self supporting pipe construction allowing a variety of layout solutions. As well as, multiple options for material of construction; from Carbon Steel with UHMW discs to full stainless steel construction. Dynaflow is offered in 3″, 4″, 6″, and 8″ pipe diameters.

Dynaflow Drag Chain Conveyors Features

- Ultra-heavy-duty conveying

- Gentle handling of fragile materials

- Maintain blends, preserving desired composition or mixture of materials or substances

- Completely enclosed for dust and contamination-free handling

- Layout versatility with three-plane circuits

- Multiple inlets and outlets

- Conveying capacities up to 10 ft3/min. / 0.28 m3/min.

- Up to 200 ft. / 60m of conveying straight-line lengths per conveyor

- Possible link of multiple conveyors for longer distances

- Low energy consumption

Our Dynaflow Drag Chain Conveyors Are "Problem Solvers in a Pipeline"

Explore How It Works and the Benefits It Brings

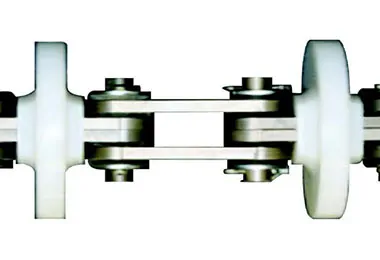

Spiroflow Dynaflow Link & Pin Tubular Drag Conveyor is a robust and heavy-duty mechanical system, encapsulated within a pipe. The discs, responsible for material transportation along the pipe, are anchored with durable metal links, making them apt for challenging applications. With the flexibility to be crafted from materials such as steel and cast iron, these conveyors can function efficiently at temperatures soaring up to 216°C (420°F).

Contamination-Free Handling, Totally Enclosed and Dust-Free

The “totally enclosed” design serves as a robust barrier, preventing any potential release of dust, particulates, or contaminants into the surrounding area.

Implementing these conveyor technologies ensures the protection of the materials being conveyed and promotes a clean and safe working environment for personnel.

Conveys a Wide Range of Materials

Capable of handling a diverse range of materials, from dry and moist to fragile, cohesive, abrasive, hot, hygroscopic, and even sludge-like.

Gentle Product Handling & Maintaining Blends

In our conveyor system, materials are channeled into spaces created between the discs inside the conveying tube. As the chain and discs glide within this closed circuit, they gently usher the material to its designated outlet. Such a delicate transportation approach not only ensures minimal wear and tear on the product but also preserves its blend consistency.

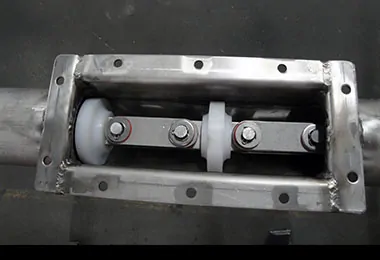

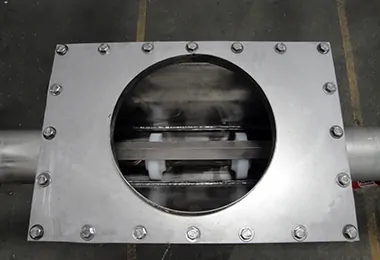

Minimal Maintenance Required

When it comes to the ongoing operation of Dynaflow conveyors, you’ll find that maintenance is a breeze. These conveyor belt systems are engineered for robust performance and are designed to minimize the need for frequent maintenance tasks.

In fact, routine upkeep is kept to a bare minimum. To ensure the longevity and optimal performance of your Dynaflow conveyor, we recommend a simple monthly checkup, focusing primarily on inspecting the conveyor’s housings for any signs of wear or damage. This proactive approach ensures that any potential issues are identified and addressed promptly.

Operates in Multiple Planes

Dynaflow is capable of conveying in the X, Y, and Z plane within a single circuit. Allowing complex layouts with a single conveyor.

Multiple Inlets & Outlets

Dynaflow is capable of layouts with multiple feed and drop points. Allowing material to be conveyed to and from multiple locations with a single conveyor.

Low Energy Consumption

Dynaflow utilizes a single electric motor in its design, allowing for low energy consumption during operation. The mechanical design requires less power to move material than a comparable pneumatic system.

APPLICATIONS

CONFIGURATIONS

Dynaflow is capable of conveying materials in three planes using a single conveyor. Spiroflow engineers will design the conveyor to best suit the material and location. Standard configurations shown below.

MODELS & SPECIFICATIONS

- Structural Schedule 40 Pipe: Carbon Steel (can be upgraded to stainless steel)

- Chain: Sealed pin, link & pin or dropped forged chain

- Discs: UHMWPE or cast iron

- Flanges: Carbon (mild) steel

- Drive Assembly

- Manual Chain Tensioner

- 1 – 30 hp / 0.74 – 22.1 kW Motor

- The motor is sized to each application.

- Multiple inlets & outlets are allowed.

- The material can be metered or flood fed depending on the product.

- Variable conveying rates

COMPONENTS & OPTIONS

Straight Pipe Sections

Curved Sections

Pipe Flange

Chain & Disc

Drive Motor

Inspection Opening

Corner Housing

Inlet Housing

Chain Vibrator

CAPACITY & SELECTION

Throughput of the Dynaflow Tubular Drag Conveyor ranges from 1.5 cu. ft. / min. up to 10 cu. ft. / min.. Throughput is dependent on conveyor size, as well as material properties and layout design.

Spiroflow’s sales and engineering team will analyze application details to help select the best conveyor for the application. Key information such as: material bulk density, layout dimensions, and desired convey rate will be required to size and design the conveyor.

Tubular Drag Conveyor Selection Guidelines

- Full metal construction and high temperature gaskets recommended for high temperature and abrasive applications.

- Larger conveyor size recommended for high throughput, as well as large particle size applications.

- Smaller diameter and UHMW disc construction recommended for long layout configurations. Dependent on material characteristics and throughput compatibility.

- Surges and uneven feed conditions should be considered. Surge hoppers may provide more constant feeding and may enable the use of a smaller conveyor.