In the pursuit of enhancing efficiency in decaffeinated tea processing, Tetley, the UK’s preferred tea brand, undertook a significant upgrade by integrating the Spiroflow Bulk Bag Discharger into their Eaglescliffe factory operations. The Spiroflow system, known for its dust-free transfer and seamless integration, exemplifies Tetley’s commitment to quality and efficiency, further cementing its status as a leader in the tea industry.

Tetley’s Journey to Improving Their Tea Production Facility

When it comes to tea, Tetley is the UK’s favorite cup! Their entire range of teas is blended and packed at their impressive factory at Eaglescliffe, Teesside, in the North East of the country, using leaf material originating from places as far apart as Indonesia, India, and Kenya. Their current output is running at 50 million tea bags per week! Much of the tea at Eaglescliffe is prepared in a blending system supplied by Spiroflow back in 2004.

So, in early 2006, they decided to improve the efficiency of their Decaffeinated Tea handling. As they wanted to start taking delivery of teas in 1,000 lb bulk bags instead of 50 lb sacks, Spiroflow was asked to propose a bulk bag discharging solution.

‘Spiroflow’ Bulk Bag Discharger – How Does It Work?

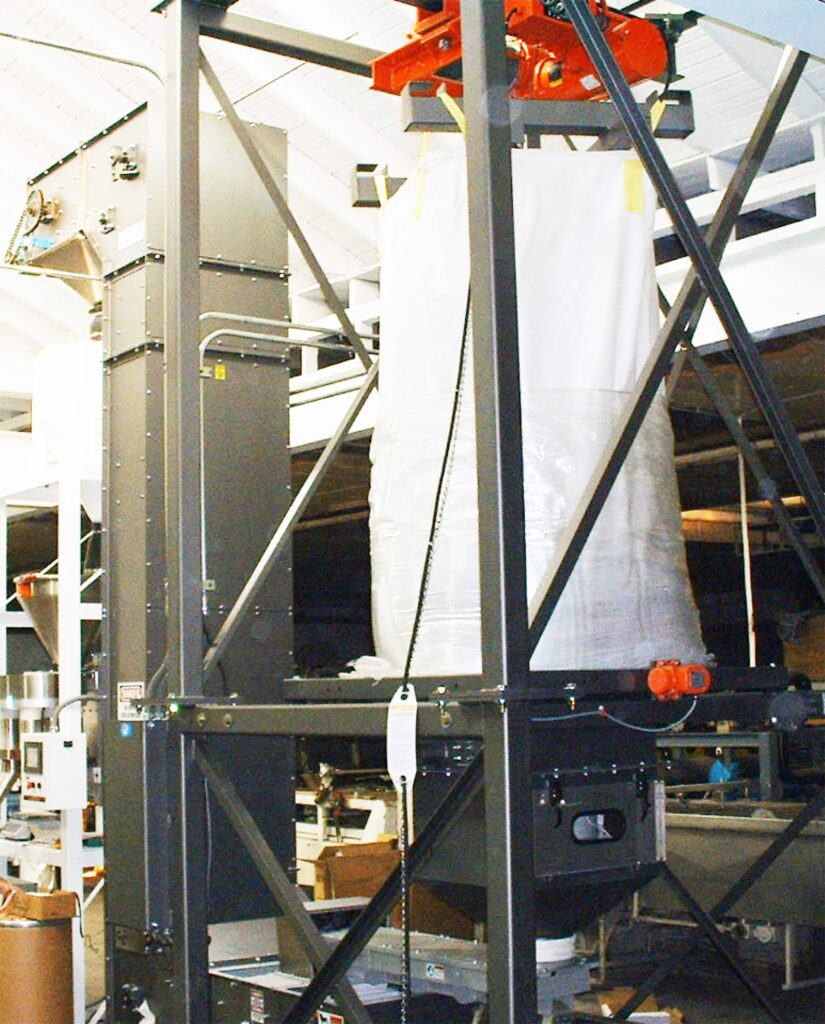

For reasons related to transportation efficiency, the tea-bearing bulk bags are delivered to Eaglescliffe stacked high on a single pallet. As a result, even though forklift trucks are used to deliver the loaded pallets to the discharger, we proposed, and ultimately supplied, one of our model T6 Bulk Bag Dischargers – which comes complete with its own bag hoisting system.

Once the loops of the upper bag are attached to a lifting frame, the bag can be hoisted up, traversed across, and then lowered into position on the discharger, leaving the forklift to undertake other duties in the meantime. Similarly, when the first bag is empty and returned to the ground, the lower bag can be installed into the discharger. Some 11 bags are emptied a day in a factory that operates 24/5.

The Efficiency of the Spiroflow’s T6 Discharger

Teas are currently discharged into the rigid containers into which the 50 lb bags used to be tipped. These containers are specifically designed to act as tumble blenders and to dock with the Decaffeinated Tea packing lines. The Spiroflow’s discharger incorporates a pneumatically operated, telescopic docking connection, which makes a dust-tight seal with the inlet of the container below. An easily removable magnet is fitted above the docking system to trap any tramp metal that may have become mingled with the tea at the point of origin.

How Does Our System Ensure Dust-Free Transfer of the Material?

To ensure the dust-free transfer of tea, the T6 Discharger is furnished with a containment cabinet in which the neck of the big bag can be untied once it has been ‘strangled’ by a pair of pneumatically powered Vee-shaped closure bars. With the interlocked dust cabinet access door closed, the Vee closure bars can be opened to allow flow to commence from the bag through the central feed spout of the docking connection into the container below.

There is an annular ring disposed concentrically around this feed spout to facilitate the escape of air displaced from the container as it fills with tea. Both the dust cabinet and the docking device are connected to the factory’s central dust collection system. This means no escape of dust into the atmosphere during the filling of the rigid containers nor each time the cabinet doors are opened to untie or retie the neck of a bulk bag.

Has Tetley Been Satisfied With Their New Bulk Bag Discharger?

The total height of the discharger is 21 ft to accommodate the 8 ft tall containers, the telescopic docking system, the bulk bag, and the lifting hoist. As Roy Goodlad, Project Manager at Tetley, confirms, “We did go out for quotes from others but, based on the competitive price offered by Spiroflow and the excellent performance of the tea blending system supplied previously, we decided to place the order for the bulk bag discharger with them. It has been installed since April 2006 and we have no complaints about its performance either.” The installation and commissioning were carried out by engineers from Spiroflow.

A Brief Overview of Tetley’s Tea Operations

Tetley is a subsidiary of Tata Tea, India’s leading tea brand, which is itself part of the Tata Group, one of India’s largest business corporations. They own Good Earth Teas, one of the USA’s most exciting specialty tea brands, and JEMA, the market-leading tea company in the Czech Republic. They also own one-third of Joekels Tea Packers, the third largest player in the South African tea market. To learn more about Tetley, their teas, and their history, be sure to check out their website.

What Are the Benefits of Using Spiroflow’s Industrial Conveyor Systems?

Spiroflow’s conveyor technologies offer unparalleled benefits to businesses seeking to enhance their material handling processes. These advanced systems are designed for versatility and efficiency, accommodating a wide range of materials and operational requirements. Their robust design ensures durability and long-term reliability, reducing downtime and maintenance costs. With options for customization, Spiroflow’s conveyor solutions can be tailored to meet the specific needs of any industry, from food and beverage to pharmaceuticals, ensuring that materials are handled safely and with the utmost care.

Moreover, Spiroflow’s conveyor systems are engineered for optimal performance, promoting increased productivity through faster, more efficient transport of materials. They also contribute to a safer workplace by minimizing manual handling, thus reducing the risk of injury. Enhanced by dust control features, these systems ensure a cleaner, healthier working environment.

Choose Spiroflow – Contact Us and Let Our Conveyor Manufacturers Create a System That Fits Your Needs

Choosing Spiroflow’s industrial conveyor systems means investing in efficiency, safety, and reliability, ultimately leading to improved operational performance and profitability. Let our expert conveyor systems manufacturers design a system that’s perfectly tailored to your specific requirements. By choosing Spiroflow, you’re setting your operations on the path to enhanced performance and increased profitability. Contact us now to start optimizing your material handling processes with solutions that are as unique as your business.