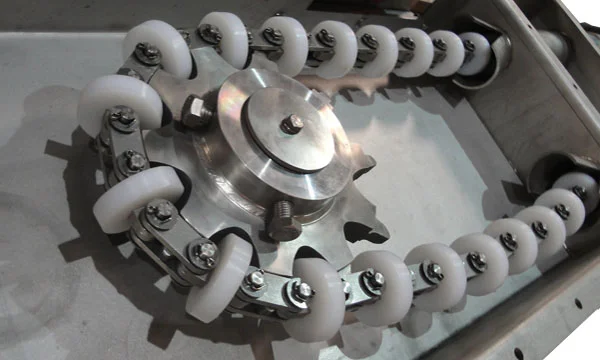

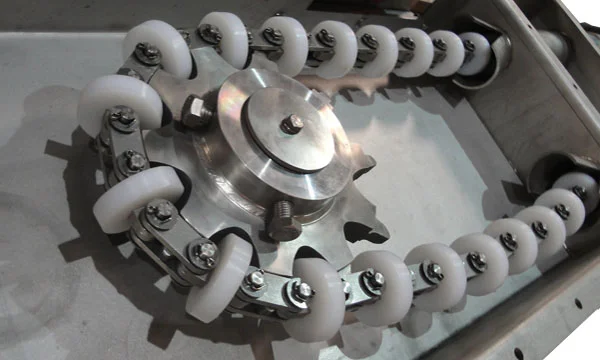

Structural Drag Chain Conveyor Problems: Keeping It Moving

Structural drag chain conveyor problems happen, but they are avoidable. I understand why you’re wondering about these conveyors. They are an expensive addition to any process, and you want to make sure you’re getting your money’s worth. This article is about helping you keep the conveyor running.

Spiroflow has been around for more than 45 years. Our team members take pride in assisting customers with their dry bulk solids and powder processing needs. This ranges from providing a simple hopper to a complete bulk material handling system. Our work isn’t done when the equipment is shipped. We want to make sure everything works well and as expected.

Best Structural Drag Chain Conveyor Manufacturers (Reviews/Ratings)

Structural drag chain conveyor manufacturers want their products to be ultra heavy-duty problem solvers for the dry bulk solids and powder processing industry.

Structural Drag Chain Conveyor – Best Materials

What are the best materials for a structural drag chain conveyor? These conveyors are problem solvers in a pipeline. That’s our nickname for them and there’s a good reason for that. If there’s a material or product that won’t convey well in another type of conveyor, an ultra heavy-duty structural drag chain conveyor built with schedule 40 pipe will likely get the job done.

How to Choose the Best Drag Chain Conveyor

Different applications need different drag chain conveyor types. We’re here to help make sure you choose the right option for your application.

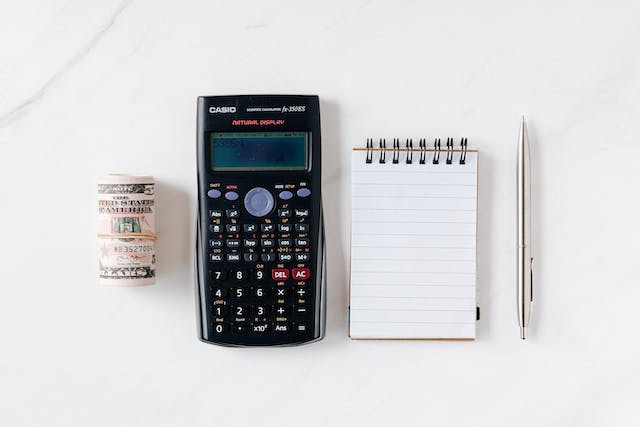

How Much Does a Structural Drag Chain Conveyor Cost?

How much does a structural drag chain conveyor cost? They aren’t inexpensive compared to other mechanical conveyors but they deliver under the most extreme conditions. The exact price depends on your layout and application parameters, but it can be worth it. These conveyors are ‘problem solvers in a pipeline’!