The food industry is one of the most important and highly regulated industries worldwide. The importance of sanitary conveyors in food processing can’t be overstated – from raw ingredients being stored under sanitary conditions to final packaging for consumers. In this article, we will discuss how conveyor solutions can help maintain sanitary conditions in the food industry.

Sanitary conveyors in food processing are specialized equipment designed to meet stringent cleanliness and hygiene standards. They feature easy-to-clean materials and hygienic design principles and often incorporate features like quick belt changes to minimize downtime for cleaning and maintenance. These conveyors are crucial for ensuring food safety and quality in the industry.

Why Is Sanitation Important In Food Processing?

The safety and quality of products that we consume depend on a variety of factors, including the cleaning and sanitation processes used to prepare them. According to the CDC, food-related illnesses and outbreaks caused by contaminated food cost the US economy more than $17 billion in 2021. The CDC estimates that there are 48 million cases of foodborne disease annually, leading to 128,000 hospitalizations and 3,000 deaths per year on average in the US alone.

Food contamination is a major public health concern not only for developed countries but also for developing regions, where it is often difficult to maintain proper sanitation standards. The World Health Organization (WHO) states that foodborne diseases result in an estimated 600 million illnesses and 420,000 deaths annually worldwide.

There’s a Step Forward With New Food Controls

The Food Safety and Modernization Act (FSMA) by the FDA is a major step forward in improving food safety requirements and preventing contamination of the US food supply. The FSMA establishes new controls for human and animal food to prevent intentional adulteration while also focusing on strengthening import/export inspection programs, among other initiatives.

Sanitation efforts must focus on ensuring that food processing equipment and facilities do not come into contact with contaminated products or other materials that could potentially transmit harmful bacteria or viruses from one location to another.

Cleaning vs. Sanitation – What Is the Best Solution for Your Conveyor Technologies

Even though they are often used interchangeably, it is important to understand that there are differences between cleaning (washing) and sanitation. The word “sanitary” implies that an object or process has the potential to reduce microbial levels on a surface, which can help protect people from foodborne illness.

The key difference comes down to whether cleaning products kill microbes (sanitation) or simply remove them (washing). The proper level of sanitary protection will vary depending on the type of food materials being transported, but it is important to understand that even a cleaned conveyor can still contain microorganisms.

Professional belt conveyor manufacturers have well-designed sanitary conveyor systems that are gentle enough not to damage fragile foods during transport. These systems also ensure the safety of workers and consumers by removing and killing any pathogens that may be present.

What Are the Standards for Maintaining Sanitation in Food Production Conveyance?

The USDA and FDA enforce stringent regulations for the design and upkeep of conveyors within food processing facilities. The FDA provides a comprehensive set of Recommended Good Manufacturing Practices that specify essential elements for preserving product safety, including:

- Ensuring that the design prevents any introduction of contaminants into the product flow during operation.

- Prohibiting the use of hazardous materials in the construction and assembly of conveyor belt systems, with a preference for stainless steel or other corrosion-resistant materials, as recommended by the FDA.

- Maintaining a conveyor that is easily cleanable and sanitizable at all times to eliminate the risk of product contamination during transportation.

- Implementing a structural design that facilitates the cleaning and disinfection of potential cracks between moving parts, such as chains and sprockets, without necessitating manual disassembly, which can lead to product contamination.

It’s important to be sure that the conveyor belts and any rollers don’t possess areas where product residues can accumulate. After all, this could lead to cross-contamination of incoming goods during processing.

These considerations are just a few of the critical factors that companies must address when designing their industrial conveyor systems. The FDA strongly advises collaborating with a food safety expert to guarantee ongoing compliance and the implementation of best practices. Neglecting these guidelines can result in product contamination, making expert consultation invaluable.

Leveraging 3-A Sanitary Standards in Conveyor System Design

When crafting a sanitary conveyor system, a valuable resource to consult is the 3-A Sanitary Standards. These sanitary standards serve as voluntary guidelines for the construction and design of processing facilities within the food industry. They provide a comprehensive framework for understanding sanitation requirements, complete with numerous illustrations to enhance comprehension across various aspects of maintaining sanitary conditions within diverse sectors.

While it’s important to note that 3-A Standards aren’t legally binding, it’s worth mentioning that some state regulations may refer to them. These standards have been in existence since the 1920s and have evolved over time to embrace emerging technologies, best practices, and insights derived from real-world experience.

Explore the Collaborative Stewards of 3-A Standards

The four associations in charge of the standards are the American Dairy Products Institute, International Dairy Foods Association, Food Processing Suppliers Association, and the International Association for Food Protection. They are supported by trade associations, government agencies like USDA and FDA, as well as various equipment manufacturers.

Some examples of 3-A Standards include specifications for materials that conveyor systems can be constructed with, proper installation and maintenance of equipment that comes into contact with food products, and procedures for receiving new conveyor systems to ensure they are sanitary.

The standards also include specifications for design elements like:

- The slope of a floor – to avoid water accumulation,

- Types of doors on an enclosure – for ease of cleaning,

- Light levels inside processing areas or storage rooms – for safety and to more easily see and inspect the processing environment.

What Are Essential Features of Hygienic Conveyor Systems?

Considering the guidelines and expertise in a conveyor belt system, there are several characteristics that are integral to sanitary conveyor systems within food processing facilities. These essential elements should include:

- Complete Enclosure

The entire system should be enclosed to prevent the infiltration of contaminants into the production line. This entails enclosing areas where products are handled or transferred, such as ingredient feeders and discharge points, along with any open spaces along the conveyors’ length to maintain the system’s sanitary conditions.

- Minimal Moving Parts and Imperfections

Reducing the number of moving parts in the conveyor system simplifies the cleaning and sanitization process. Minimizing the presence of nuts, bolts, screws, and joints is crucial to mitigate the risk of product accumulation. Additionally, the conveyors should be designed to be smooth and seamless, leaving no nooks where food residues can accumulate.

- Stainless Steel Connectors

Employing stainless steel connectors, as mentioned earlier, is the ideal choice for constructing conveyors, as these materials are resistant to corrosion and rust.

- Clean-In-Place (CIP) Technology

Integration of CIP technology is a valuable feature for automated machinery cleaning with chemical solutions. Conveyor systems should be CIP-enabled, allowing food processors to implement a comprehensive sanitization program based on preset cycles and schedules.

This method involves applying chemicals to eliminate residual product particles and residues that may have accumulated over time in the system. An additional advantage of CIP is that it obviates the need for disassembling the conveyor system during cleaning, reducing downtime and enhancing the overall efficiency of the cleaning process.

Explore the Optimal Choices for Sanitary Conveyors

When it comes to selecting the most hygienic conveyor systems for food processing, here’s a summary of the key features discussed earlier. The top preference would be a conveyor system constructed from stainless steel or other corrosion-resistant materials, enclosed with minimal moving parts and crevices, and equipped for Clean-In-Place (CIP) technology.

The following conveyor systems meet some or all of these requirements:

- Belt Conveyors

These are among the most prevalent types of conveyors used across industries. To meet sanitary standards, food-grade conveyor belts should be crafted from non-porous materials and can also be enclosed if necessary. However, it’s important to note that they require a considerable amount of floor space and are generally limited to horizontal or near-horizontal operations.

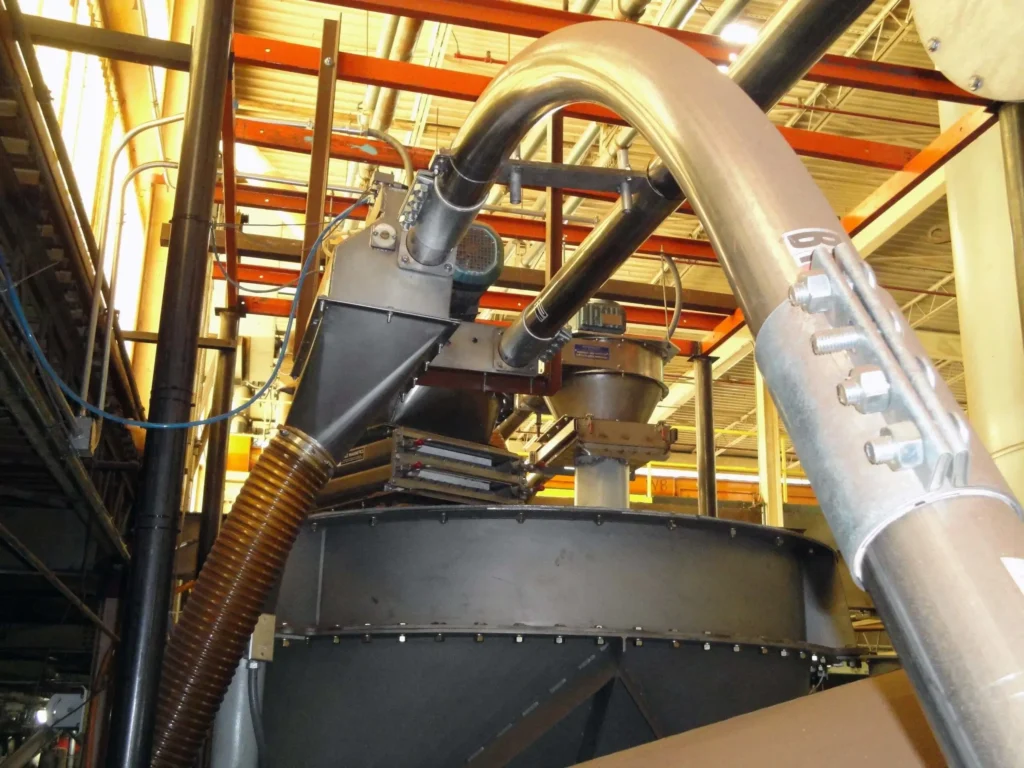

- Tubular Drag Cable and Disc Conveyors

Depending on the specific food material you are handling, tubular drag cables and disc conveyors can be a top choice. The cables, often made of stainless steel coated with smooth nylon for contact with food products, resist acids and chemicals, making them suitable for food processing.

These cables are enclosed in tubes to further safeguard the product from contaminants. Solid discs with no crevices, nuts, or bolts assist in moving the material. This system can be customized to accommodate various food products, enhancing its versatility.

- Chain Drag Conveyors

Chain drag conveyors, similar to tubular cable drag conveyors, feature a stainless steel chain and can be enclosed for sanitary operation. However, it’s worth noting that chains may not be the ideal choice for transporting food materials, as they can accumulate product residues, potentially leading to contamination issues if not cleaned thoroughly.

- Pneumatic Conveyors

Typically constructed from stainless steel, pneumatic tubes can be either horizontal or slightly inclined for gravity flow. To maintain hygiene, they should incorporate a top-end filter to prevent the ingress of particles during operation. Pneumatic tubes can also be equipped with CIP technology, making them suitable as sanitary conveyor options. Without CIP technology, however, pneumatic tubes may pose challenges for cleaning due to limited accessibility.

Prioritizing Hygiene: Cleaning Protocols for Conveyor Systems

No matter which conveyor manufacturers you choose, it’s imperative to integrate a meticulous cleaning regimen into your overall sanitation program. The utmost priority in conveyor cleaning lies in the comprehensive removal of all product residues, regardless of their minuscule size.

Implementing a consistent cleaning schedule offers numerous advantages, including safeguarding products from potential contamination, prolonging the lifespan of the conveyor, and upholding safety standards for workers.

What Cleaning Alternatives Are Available for Conveyor Systems?

Cleaning options for conveyor systems can broadly be categorized into two primary approaches: manual cleaning and automated cleaning. The choice between manual and automated cleaning methods depends on factors such as the type of conveyor system, the extent of contamination, and the resources available. Automated cleaning, especially CIP, is preferred when efficiency, thoroughness, and reduced downtime are essential.

However, manual cleaning methods may still be suitable for specific situations, and regular visual inspections should complement any cleaning regimen to ensure the highest standards of cleanliness and sanitation in food processing facilities.

Challenges of Manual Cleaning

Many facilities still utilize manual cleaning, where workers wear gloves and use brushes or scrapers to remove visible residues. The frequency of this cleaning varies depending on the transported food product and residue left behind. Manual cleaning has limitations: it may not fully remove contaminants, consumes time, and poses risks to employees not following safety guidelines.

Automated Technologies – CIP and COP Cleaning

Automated cleaning solutions, like Clean-In-Place (CIP) systems, offer significant advantages over manual cleaning. CIP is more efficient, eliminates contamination risk, and doesn’t require disassembling the conveyor system. It’s a tool-free, interruption-free cleaning method. Cleaning Out of Place (COP) systems, while slightly more time-consuming than CIP, are still more efficient than manual cleaning.

Establishing Effective Conveyor Cleaning Protocols

Every conveyor manufacturer has its own set of cleaning protocols that must be followed when it comes to sanitizing their conveyors. The manufacturer should also provide thorough instructions on how to install and operate the system, as well as perform regular cleaning procedures.

For example, Cablevey offers two types of cleaning for their systems: wet and dry cleaning. Dry cleaning may include one or several of these items:

- Air knife – Using compressed air to blow off the conveyor line.

- Brush box – A line insert with brushes used for cleaning.

- Sanitizing cleaner and sponge box – A combination of sponges and sanitizing chemicals.

- Urethane wiper disc – The wiper disc is used to wipe off any remaining residue from the inside of the conveyor.

In contrast, wet cleaning consists of the following steps:

- Water rinse – A high-pressure water spray rinses the conveyor, getting it ready for the next wash step.

- Foaming agent – The purpose of the foaming agent is to clean the inside of the conveyor, removing any remaining residue.

- Sanitizing agent – The sanitizing agent is used to kill any microorganisms that may still be present on the conveyor.

- Second water rinse – The last step in the cleaning process is a water rinse, which makes sure all residues and chemicals are removed from the system before it can start operating again.

The methods mentioned above are specific to tubular drag conveyors and may not be available for other systems. Before you settle on a new flexible screw conveyor or traditional belt conveyor system, make sure to do some research first on the cleaning protocol capabilities of each manufacturer.

Effective Sanitization Must Have Validation, Monitoring, Verification

A successful sanitization protocol hinges on robust validation, monitoring, and verification methods. Validation ensures the desired outcomes while monitoring checks the execution of each step, and verification detects any lingering residues.

Validation involves microbiological and non-microbiological tests. Microbiological tests employ culture cultivation and molecular techniques to detect remaining microorganisms. Non-microbiological tests, including visual inspections, ATP tests, and protein assessments, confirm proper cleaning and rinsing.

Thorough validation and verification are essential to guarantee the hygiene of the conveyor belt systems and prevent potential contamination risks to consumers.

Adenosine Triphosphate (ATP) Testing: A Crucial Tool for Cleaning Protocol Evaluation

Assessing the effectiveness of your cleaning protocol can be efficiently accomplished through ATP (adenosine triphosphate) testing of conveyor surfaces. ATP, which serves as an energy source in living organisms, is prevalent in various sources, including food residue, bacteria, mold, and even human skin.

ATP surface tests are highly efficient and sensitive. Simply swabbing both vertical and horizontal surfaces following the cleaning stage (but before sanitization) can gauge the cleaning process’s effectiveness. Elevated ATP levels suggest the need to fine-tune the cleaning protocol.

Customized ATP Thresholds for Effective Cleaning

What distinguishes this testing method is the absence of a universal ATP threshold applicable to all surfaces and conveyors. Pass or fail criteria depend on variables like surface age, material composition, the specific products in contact with the surface, and the cleaning techniques employed.

To establish a realistic ATP limit tailored to your specific surfaces, you should undertake an extensive program of ATP swabbing and testing over a prescribed period, usually spanning two to three weeks. This process allows for the establishment of customized benchmarks for your distinct application.

Spiroflow Has the Best Sanitary Conveyors in Food Processing

In the food industry, sanitary conveyor belt solutions are crucial for consumer safety. To ensure a system that’s both effective and easy to clean without disrupting productivity, thorough research is vital. Conveyor systems manufacturers should provide clear guidance on installation and cleaning procedures.

The ideal sanitary conveyor for food processing should be enclosed with no areas for residue or bacteria to hide yet easily accessible for cleaning without full disassembly. If you’re looking for enclosed conveyors with efficient cleaning, material-friendly design, and energy efficiency, please contact us. Experts at Spiroflow are here to help you find the best solution for your company.