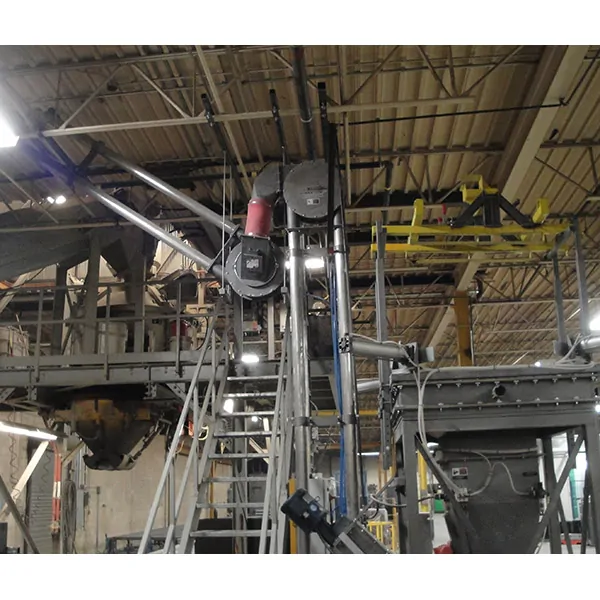

Determining the aero mechanical conveyor cost involves various factors, making it a common inquiry among those looking to enhance their material handling processes. The price hinges on construction materials, the layout of the plant, and the specific features selected for the conveyor.

With efficiency and customization at the forefront, the Spiroflow conveyors represent a valuable investment for efficient material transfer, embodying a balance of high performance and cost-effectiveness that adapts to diverse operational needs.

How Much Does the Aero Mechanical Conveyor Cost?

An aero mechanical conveyor is one of the most efficient ways to move material in a plant, but how much does it cost? We get this question all of the time. However, there’s not a simple answer because it depends on several factors, such as construction materials, layout, and selected options. We’ll describe all of the determining factors and why an aero-mechanical conveyor could work for you.

What Is an Aero Mechanical Conveyor?

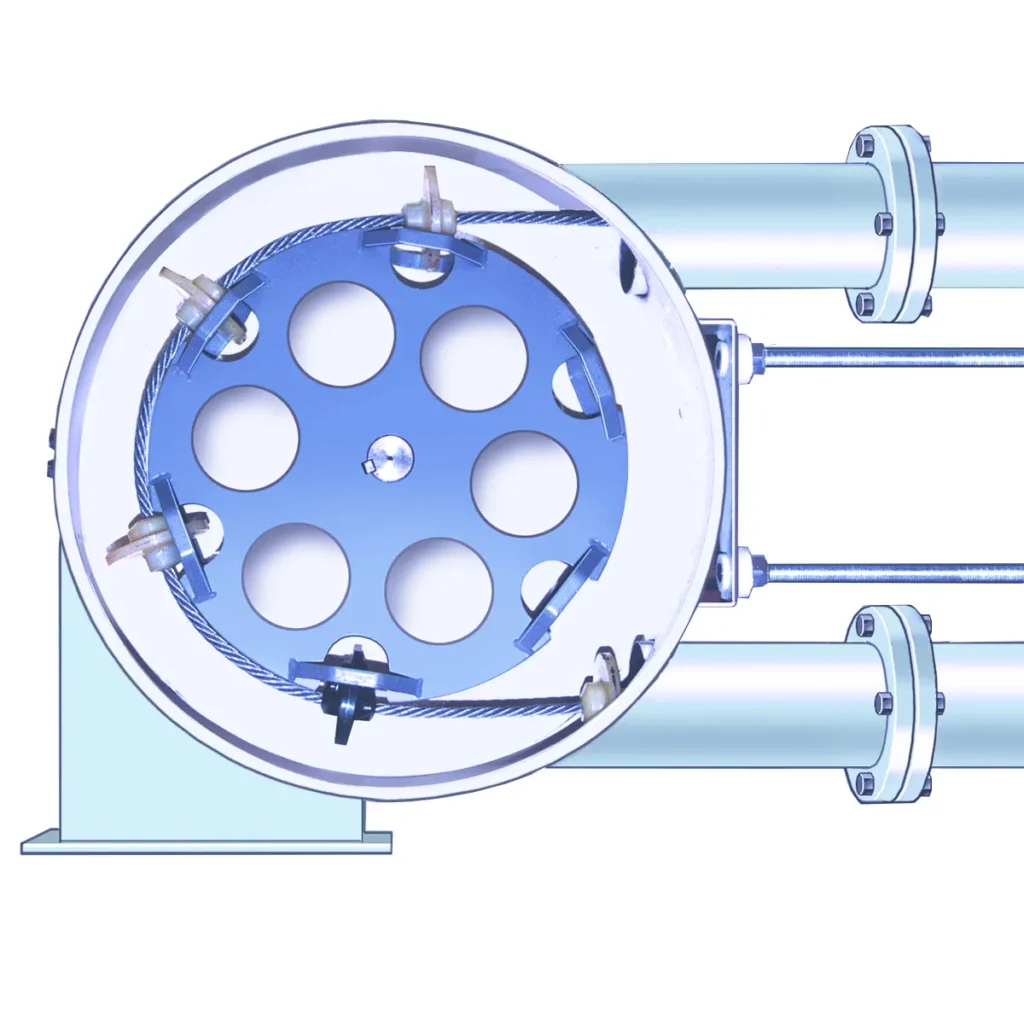

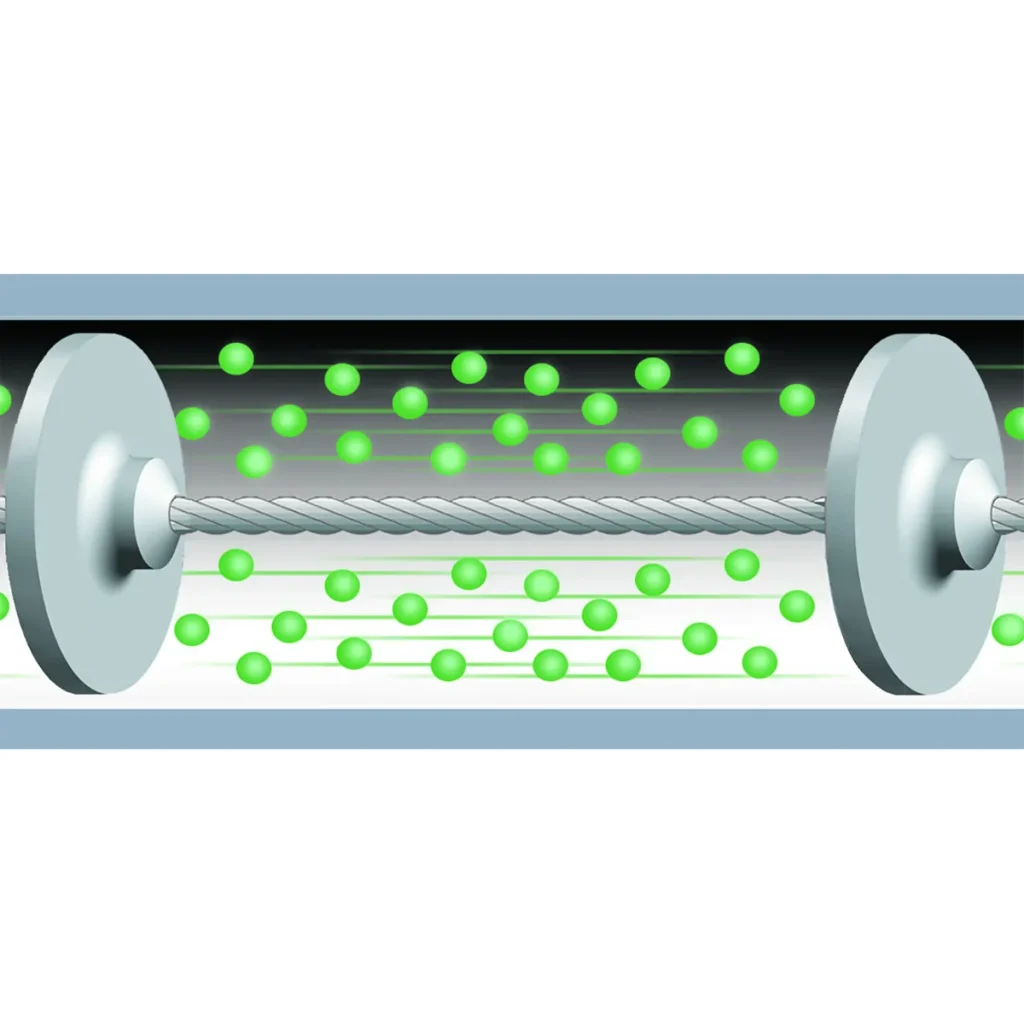

An aero mechanical conveyor (AMC) transports materials from one location to another efficiently and quickly. It operates with a cable and attached discs, generating an airflow that propels the material along its path.

The swift motion prevents materials from sticking to the interior of the tube. Each segment contains approximately 80% air and 20% material, ensuring complete batch movement with Spiroflow‘s conveyors.

Material Compatibility and Testing in Aero Mechanical Conveyors

Aero mechanical conveyors are utilized in many industries to convey material that’s dry, moist, and/or cohesive. We recommend material testing, no matter what your product is.

Material testing is highly recommended if you need to convey fragile, abrasive, hygroscopic, or fine particles in an aero-mechanical conveyor. Slurries and sludge-like materials cannot be conveyed in an AMC.

The Impact of Construction on Aero Mechanical Conveyor Costs

How an aero mechanical conveyor is constructed plays a huge role in the cost. These systems are crafted with stainless steel tubes, ensuring durability and longevity. Depending on specific operational requirements, the cables can be fashioned from either carbon steel for robustness or stainless steel for enhanced corrosion resistance.

Complementing this, polyurethane discs ensure efficient material transfer while minimizing wear and tear. This thoughtful selection of materials guarantees the conveyor’s performance and its adaptability to various industrial environments.

Size Options Influence the Final Bill as Well

Spiroflow provides aero mechanical conveyors in three distinct sizes to accommodate customers’ diverse needs. Our tube diameters are available at 3 (75mm), 4 (100mm), and 5 inches (125mm).

Explore the Operation Flexibility and Customizable Layout of These Conveyor Solutions

Spiroflow is one of the leading conveyor manufacturers. We design our aero-mechanical conveyors to offer operational versatility, significantly contributing to their efficiency. Key features include:

- Multiple inlets and outlets for streamlined material flow.

- Connectivity between several conveyors to cover greater distances.

- Up to 90° conveyor bends for flexible layout integration.

- Dual-plane operation to maximize space utilization.

- Designed for metered feeding for precise control.

- Ability to operate without material, offering operational flexibility.

The Speeds and Capacities of These Conveyor Technologies Also Impact the Price

Speed and capacity rates can vary depending on the material in your process. The cable speeds can run as high as 1,200 ft/min (365m/min), and capacities are typically up to 36 ft3/min (1.0m3/min). There are no variable conveying rates with AMCs.

Added Features and Options Are Also Key Contributors to the Price

Cleanability is a topic that customers often ask about. The wash gate and drain are useful features if cleanability is a priority for you. They allow you to cycle hot and soapy water through the conveyor. Run your system to empty it of water and dry it for about one hour. However, this conveyor can also be dry-cleaned. Operators can run a material like salt to remove any residual product.

Our exclusive Dynamic Automatic Rope Tensioning system employs an air cylinder within one of the enclosures to consistently apply pressure to the rope/cable, compensating for natural stretching. This innovative system automatically manages the sprocket’s tension, eliminating the need for manual adjustments and ensuring the rope/cable remains engaged with the sprocket, thus averting operational breakdowns and ensuring uninterrupted workflow. Below are additional features worth exploring:

- Hytrel discs,

- Corner sprockets,

- Inlet base support,

- Hinged access covers,

- Electric or pneumatic inlet vibration,

- Extended capacity chute,

- Dust hood,

- Splash guard,

- Pneumatic inlet baffle,

- Rotation sensor,

- Level indicators,

- Mobile base,

- Explosion proofing,

- Food grade construction,

- Controls.

What’s the Price of an Aero Mechanical Conveyor?

Now it’s time to answer the most asked question our sales team receives. The cost of an aero mechanical conveyor typically runs from about $25,000 (£19,500) to $60,000 (£47,000).

It’s also worth mentioning that AMCs have low maintenance costs, especially with the addition of an auto-tensioning system. You can expect to replace the cable every 2,000 to 6,000 hours of operation.

These conveyors consume a low amount of energy. The motor of a typical AMC ranges from 2-3 hp. The lower energy draw is a huge advantage over pneumatic conveying systems. Pneumatic conveyors use much larger motors and cost more to run when compared to AMCs.

Discover More About Spiroflow’s Comprehensive Solutions

Give Spiroflow a call or send us an email if there’s anything you’d like to know, as we don’t just design and build aero-mechanical conveyors. You can check out our full line of products here, which includes a variety of conveyor belt solutions, including a flexible screw conveyor, among others. We also do control systems integrations. Make sure to contact us today, and we’ll make the conveyor suit your needs and give you more information on our automation solutions.