Let’s compare aero mechanical vs. pneumatic conveyors, two popular types of industrial conveyor systems. Discover their unique features, how they work, and where they’re best used. Whether you’re in the industry or just curious, this easy-to-understand guide will help you understand the differences between these conveyor solutions.

Aero Mechanical vs. Pneumatic Conveyors – Which is Better?

Here at Spiroflow, we’ve been in the conveyor technologies industry for more than 45 years. Given our experience, we find that aero mechanical conveyors are often a better option in many different types of processes. That being said, we’ve sold both types of conveyors over the years, and it’s important to first consult an engineer to understand if mechanical conveying (mechanical part moves material) or pneumatic conveying (air or gas moves material) is the best way to move your material. To help you understand the benefits of aero mechanical conveyors, we’re putting them up against pneumatic conveyors in today’s showdown.

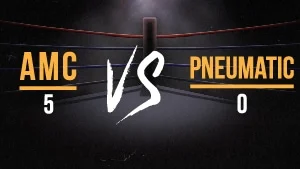

Mechanical vs. Pneumatic – 6 Round Showdown

As we gear up for an in-depth comparison between mechanical and pneumatic conveyor systems, it’s essential to start with the basics. In this 6-round showdown, we aim to settle the long-standing debate about which conveyor type reigns supreme in various industrial scenarios. It’s time to settle the score. But first, some definitions.

What is an Aero Mechanical Conveyor?

An aero mechanical conveyor, or in short – AMC, is a type of tubular conveyor utilizing a cable and disc assembly. The movement of the conveyor is so rapid it aerates the product. As a general rule, each pocket contains about 80% air and 20% material. It is one of the most efficient methods of conveying materials. Its dust-free and clean handling properties make the conveyor a good fit for many applications across several industries.

What is a Pneumatic Conveyor?

A pneumatic conveyor transports materials using a stream of gas, typically air, to suspend the particles. By carefully introducing materials into the airstream at a specific ratio of solids to air, a vacuum pump generates a differential air pressure. This pressure creates sufficient velocity to carry the materials through the conveying tube. Pneumatic conveying is a simple option to move material across challenging routes. The product is moved hygienically and is a good fit for several applications.

Differences Between Aero Mechanical Conveyors and Pneumatic Conveyors in 6 Rounds

Now, let us evaluate several characteristics that are important in considering the right conveyor for your dry bulk material handling needs. We’ll start with energy consumption, noise levels, and venting.

Round 1 – Which Conveyor Is More Energy Efficient?

Is limiting power consumption a priority? Aero mechanical conveyors can convey material at a rate from 9 ft3/min (11.8 m3/hr) to 36 ft3/min (51.9 m3/hr), depending on the diameter of the tube. These conveyors can pull this off by using a drive motor between 2-7.5 hp through a gearbox. Pneumatic conveyors require a 20-40 hp blower to reach comparable rates to an AMC.

Round 2 – Which Conveyor Is Quieter to Run?

In this round, we focus on the noise each conveyor produces. Aero mechanical conveyors are the quieter choice, operating below 85 dBA, making them suitable for environments where noise is a concern. Pneumatic conveyors, in contrast, are much louder. To reduce their noise, they often need to be placed remotely or fitted with mufflers, which can increase costs. This round highlights the importance of considering noise impact in your conveyor selection.

Round 3 – Which Conveyor Has a Better Venting System?

One of the major advantages of an aero mechanical conveyor is that it’s a balanced system. Ambient air is drawn into the conveyor along with the material, and the material is discharged at the outlet of the conveyor. The displaced air is drawn back into the conveyor, creating a balanced system. There are no special venting or filtering requirements because there is no pressurization at the discharge point.

Pneumatic systems handle venting differently. A receiver is utilized that requires venting of the motive air. Compressed air is also required for backwashing the filters and valves required for proper operation. Pressure systems require venting with filtration for the receiving vessel, with exhaust entering into the surrounding area or vented outside the building. Vacuum systems generally draw motive air from the surrounding area. It is important to determine if special air conditioning or additional climate control will be required in these areas. This could greatly increase the cost of heating or air conditioning and should be factored into your budget.

Round 4 – Which Conveyor Is Best for Layout Optimization?

Multiple inlets and outlets can easily be integrated with aero mechanical conveyors. When multiple outlets are used we recommend that the conveyor operates at half speed. This ensures that the material exits the conveyor properly. A tube valve at each outlet provides a smooth path for the ingredient to pass through.

Multiple outlets on vacuum conveyors require a separate receiver, its own pressurized air supply for filter cleaning as well as its own feed control valve and diverter valves. Additional piping is also needed to feed each individual usage point. Each receiving point requires venting of the motive air as well as filters, valves, diverters, and additional piping to direct product to each use point for pressure systems.

Round 5 – Which Conveyor Is Best to Prevent the Separation of Materials and Maintain Blends?

Aero mechanical conveyors are considered gentle conveyors. Pocket fill is typically 80% air and 20% material. The air stream carries the product around any corners in the system, and mixtures are maintained throughout the conveying process.

Pneumatic conveyors use a similar air-to-material ratio. The entire length of the circuit is under the same pressure or vacuum. Because of centrifugal force, the product hits the walls of the tube hard. This can lead to degradation of the material and wear on the machine. Blends are more likely to separate while being conveyed over long distances.

Round 6 – Which Conveyor Is Easiest to Clean?

Aero mechanical conveyors will transfer virtually all of the material introduced into the conveyor. Air purging is an option to clear out any residual material. Another option is dry cleaning, running a material like salt inside of the conveyor. Wash gates and drains are included when the application requires the system to be wet-washed. When wet washing, the AMC creates an agitation effect, like a dishwasher, that completely washes the inside of the conveyor. The conveyor can run while empty to dry out.

Pneumatic conveyors are also easily cleaned. They can be dry cleaned using salt to scour the conveyor. For wet cleaning, a “pig” is pushed through the piping system using compressed air. Since both conveyors are easily cleaned, this round is a tie.

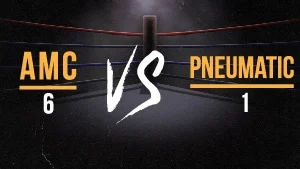

Let Us Announce the Winner

While aero mechanical conveyors have considerable benefits across industries and processes, it’s difficult to say which conveyor will truly work best for your process without an engineer knowing more about your operation. Not all processes are the same. At Spiroflow, we have a team of engineers in the United States and the United Kingdom who can help you. Feel free to contact us if you have any more questions.