In the world of material handling and conveyor belt systems, efficiency and cost-effectiveness are paramount. Still, you need to know all the factors that influence the drag chain conveyor cost before you integrate this innovative technology into your operations. Let’s dive deep into this topic and help you gain a clearer understanding of the investment required and how to make informed decisions for your material handling needs.

On the low end, tubular drag chain conveyors cost $12,000 (£9,800). On the high-end, these conveyors can cost around $70,000 (£57,000). However, the cost of these conveyor technologies can vary widely. Several factors, including conveyor length, material type, and additional features, influence the final price.

How Much Does a Tubular Drag Chain Conveyor Cost?

The question of how much these conveyor solutions cost is common in the conveying industry. Tubular drag conveyors have been manufactured and used by customers globally for years, and the cost can vary significantly due to various factors. Determining the precise cost isn’t straightforward, as it hinges on individual circumstances.

Variables such as the conveyed material and specific application requirements play a crucial role in pricing. To get a bigger picture of how big an investment this is, you should grasp the key variables involved.

Explore the Main Types of Tubular Chain Conveyors

Although belt conveyor manufacturers are more affirmed and have been present in the industry for many years, we need to acknowledge that the technology is evolving. That’s how today we have tubular chain conveyors.

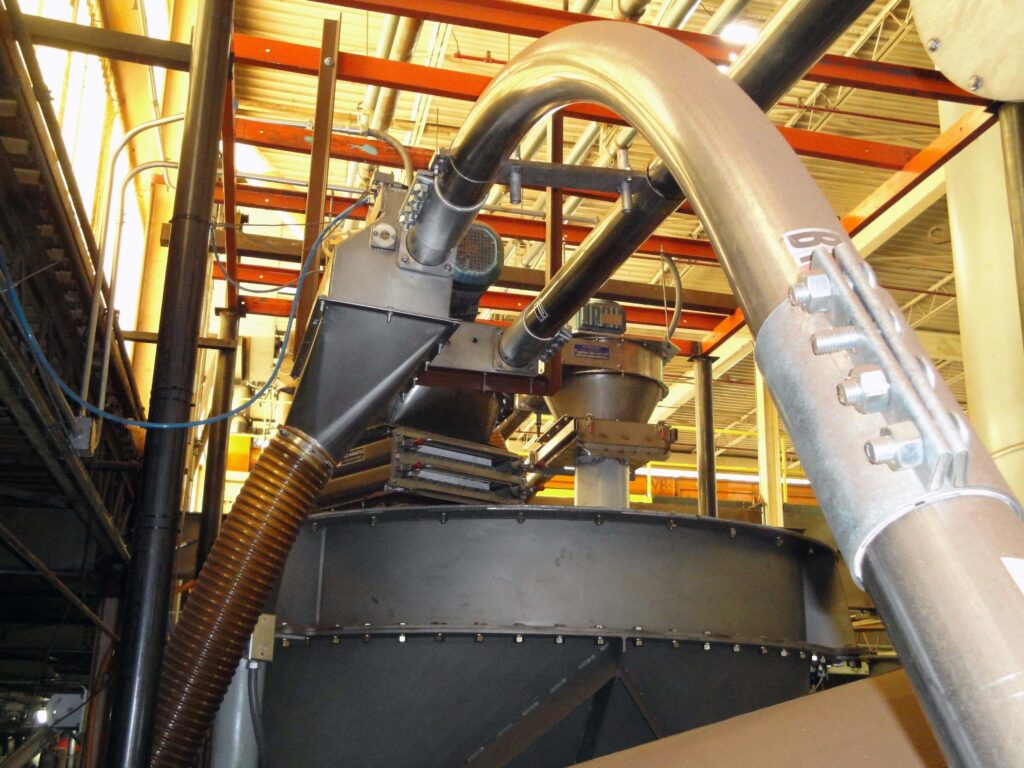

These come in several sizes and differing construction options. At Spiroflow, you can find two types of drag chain conveyors: heavy-duty tubular drag conveyors that utilize stainless steel tubes and structural ultra-heavy-duty drag chain conveyors that utilize structural pipe.

In the video below, you can check out how Dynaflow tubular chain drag conveyors move chemical prills.

Why Do I Need a Tubular Chain Conveyor?

Tubular drag chain conveyors are specifically designed for gentle material handling and minimal product degradation. These heavy-duty, dust-free conveyors are highly cost-effective for efficiently transporting or batching dry powders and fragile materials such as coffee beans, cereals, nuts, dried fruits, grains, candies, and more.

Their hygienic design, boasting seamless UHMWPE discs and a durable stainless steel chain assembly, makes them a preferred choice among food processors. Whether used in food processing or industrial conveyor systems, tubular drag chain conveyors excel at maintaining product integrity during transport.

Advanced Conveyor Design for Precision Material Handling

Unlike the traditional conveyor belt system, this system consists of a series of straight and curved tubes with custom-designed layouts to suit your site and application needs. It forms a closed circuit, allowing products to enter and exit through tube-mounted chutes. Inside the stainless steel tube, a seamless disc and chain assembly operate without crevices. These discs move material through the circuit, driven by a sprocket at one end.

Additional sprockets can be incorporated for smooth directional changes and reduced system load. Tension in the chain is maintained by a pneumatically actuated tensioning assembly located within the 180˚ idler housing.

First Step of the Tubular Drag Conveyor Pricing Process – Understanding Your Application

Whether it’s conveyor belts or tubular drag systems, making safe, effective, economical, and reliable equipment is the goal of every manufacturer. However, in order to achieve that, you’ll need to know all the details of your process. The specifics of your application will determine the overall cost, so with that in mind, let’s go over all the details you’ll want to know during the buying process.

Characteristics of Your Material

Determining the characteristics of the materials you’ll be working with is a fundamental step in various industries and applications. Here are the things you should think about before investing in a tubular drag and flexible screw conveyor or other conveying systems:

- Particle size,

- Material form (powder, granule, or pellet),

- Material characteristics,

- Bulk density,

- Temperature,

- Hopper characteristics,

- Flow characteristics (angle of repose),

- Liquid/Fat content,

- Required capacity.

Conveying Capacity Requirements

Whether you’re managing bulk materials in a manufacturing plant or handling goods in a distribution center, accurately determining your conveying capacity needs is essential. To do that, you should answer the following questions:

- What rate do you require? (ft3/hr or m3/hr) (lb/hr or kg/hr)

- How many hours/day will the conveyor run?

- What’s your feed source? How many inlets are required?

- Will you have a controlled feed rate or surge feed?

- What’s your conveying distance?

- How many discharge points?

Equipment Specifications

When it comes to determining tubular conveyor equipment specifications, it’s best to answer the following questions:

- What construction materials are required?

- Do you require 316 or 304 stainless steel chains and tubes?

- What are your motor specifications – TEFC, Mill & Chem., Explosion Proofing, Inverter Duty, Washdown Duty?

Optional Items

There are many options, and each will potentially affect the final price. Don’t worry if you are not sure what you need – as drag conveyor experts, the team at Spiroflow can explain the pros and cons of each and suggest which options you would benefit from most. Going over all the details will allow you to make a decision based on your application needs and budget. Here is a list of options that are available with Spiroflow tubular drag conveyors:

- 90° Corner Housings,

- Hinged access covers,

- Hinged inlet chute access covers on corner sprockets,

- XP switch for hinged housing access cover,

- 15°, 30°, 45°, 60° or 90° tube bends or bends at other angles,

- Tube-mounted inlets with adjustable baffles and lids,

- Tube-mounted outlets,

- Hopper with safety grid, lid, and dust hood assembly,

- Hopper vibration – electric or pneumatic,

- Hopper agitator,

- Level indicator,

- Air purge,

- Clean out disc assembly,

- Tube valve with chute (pneumatically actuated inline discharge valve),

- Tube valve outlet transition chutes,

- Rotation sensor (highly recommended),

- Static grounding,

- Controls (with or without VFD),

- Mobile base.

Material Testing

It’s highly recommended to test your material when considering purchasing any conveyor. Material testing allows the manufacturer to verify the performance of the recommended conveyor under actual operating conditions, which provides you with the ultimate peace of mind. We at Spiroflow conduct material tests in our test labs in the US and the UK. Customers can attend the test in person, or we can share a video of the test.

Choose One of the Most Reliable Conveyor Systems Manufacturers

As your operations rely on the smooth and continuous movement of materials, you need a trusted partner who understands your unique requirements and can deliver dependable, top-tier solutions. At Sparoflow, we’ve built a reputation for excellence in designing and manufacturing both traditional conveyor belt solutions and modern tubular drag systems.

Contact us today, and let’s discuss your specific needs, explore our seamless tubular drag and belt conveyor system, and discover how we can elevate your material handling processes to new heights.