If your product has certain characteristics that make it difficult to handle, you may be asking yourself – how do you convey a difficult product? The right conveyor for your application is based on a number of factors, including material characteristics, layout, and application. At Spiroflow, we help you choose the right conveyor to achieve your process goals.

How Do You Convey a Difficult Product?

Numerous products can pose difficulties for conveyor systems, but based on our extensive 45 years of experience, the aero mechanical conveyor emerges as the top choice for managing challenging items. In this article, we’ll explore the factors that make a product tough to convey and demonstrate why the aero mechanical conveyor is the most effective solution for these situations.

Properties of Difficult Product

Your product might appear simple to transport, yet it could possess properties like being explosive, corrosive, moisture-absorbing, or abrasive. All these characteristics significantly influence the method of conveying it. Such factors can present considerable challenges in the transportation of your material.

Flow Characteristics

Does your material move slowly or flow freely? The behavior of the material during conveyance and unloading is a key consideration in our equipment design process. If your product tends to move sluggishly or experiences bridging while being conveyed, it might require extra flow aids. By conducting a material test, we gain insights into the unique flow properties of your product, enabling us to suggest the most suitable equipment for your process.

The Material Abrasion

Is your material prone to causing abrasion? Knowing the extent of its abrasiveness is crucial in determining the construction material for your conveyor. In designing your equipment, our goal is to maximize its lifespan, which we achieve by minimizing the points of contact.

Material’s Temperature

Temperature encompasses several aspects, including the temperature of the material, the temperature during conveyance, and the ambient temperature within your facility. All these factors influence the behavior of your material during processing and consequently affect the design of the equipment tailored for your process.

Testing the Product

Should your product be described as ‘challenging to manage’ due to its friable, sticky, hygroscopic nature or its tendency to cake or pack, it can present handling difficulties. For products that are tough to handle, conducting laboratory tests is crucial for us to comprehend their behavior. Following these lab tests, conducting machine trials provides a comprehensive understanding of how your product behaves during conveyance, helping to prevent any possible future complications.

We test for the following at Spiroflow:

- Blending and mixing – Separation of mixtures and combinations can pose an issue during transport, so our evaluation will determine whether or not your product experiences separation. This information will be crucial in deciding the most suitable conveyor for your needs.

- Rate of flow – Powders exhibit a wide range of flow properties. While some powders are prone to compacting or caking, others may fluidize when in motion. Our machine testing aims to identify the specific flow behavior of your powder, aiding in the design of the equipment and guiding your selection process.

- Particle properties – The composition and characteristics of bulk solid materials and powders, such as particle size, shape, and density, can differ significantly. Therefore, comprehending the specific attributes of your product is essential in designing and selecting the appropriate equipment.

You can view a full list of our product database to find out specific information about your product.

The Aero Mechanical Conveyor Principle of Operation

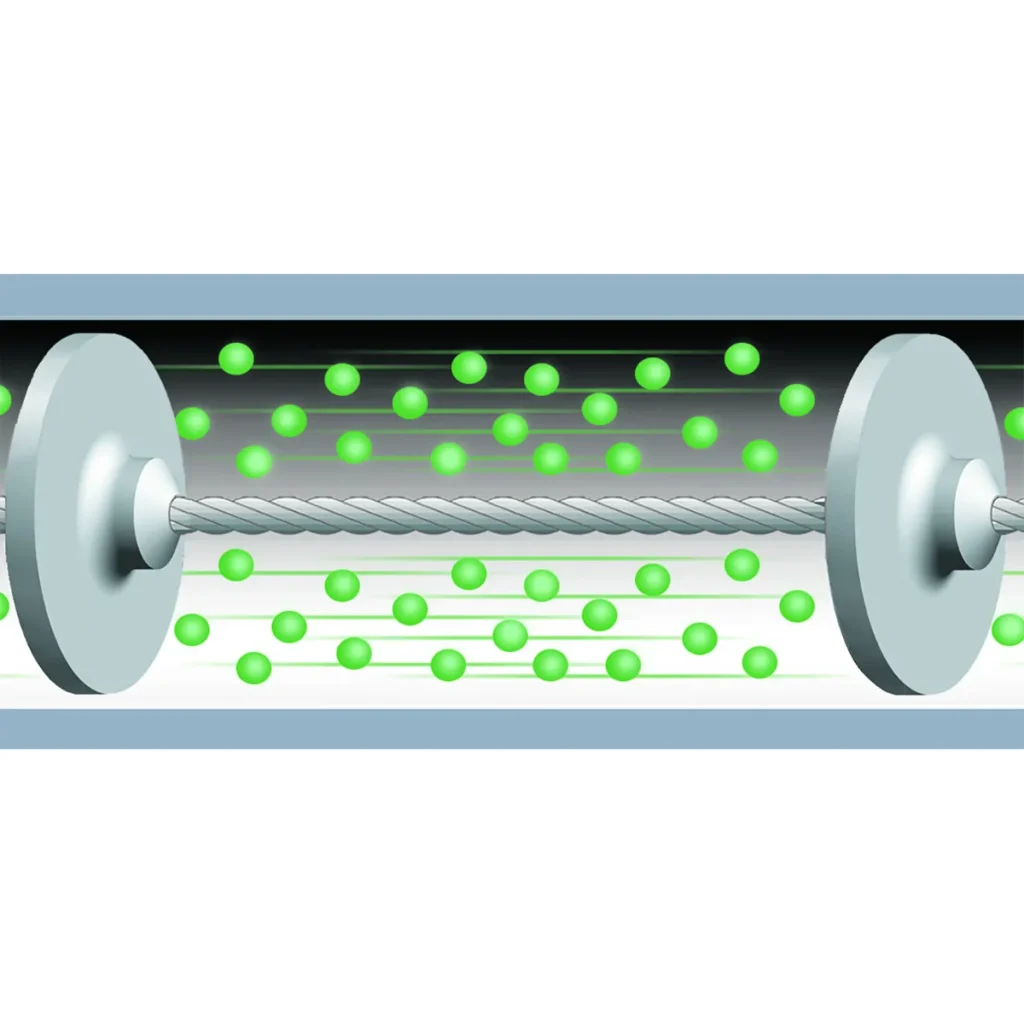

Our Aeroflow aero mechanical conveyors feature a cylindrical structure where a continuous wire rope assembly, equipped with precisely spaced polyurethane discs, operates at high velocity. The rope assembly is guided by specially crafted sprockets at both ends of the conveyor; one sprocket is responsible for driving the rope assembly while the other maintains its tension. Depending on the conveyor’s length or specific plant needs, the drive assembly can be positioned either at the inlet or outlet.

The high-speed motion of the rope and disc assembly creates an airstream moving at the same speed. When material is introduced into this airstream, it becomes fluidized and is transported to the outlet, where it is ejected through centrifugal force. This method allows for high-capacity conveyance with low energy consumption while minimizing product degradation and separation. Due to its effectiveness in transporting materials, the aero mechanical conveyor is particularly adept at handling titanium dioxide, a product known for its challenging conveyance properties.

Controlled Feeding

When running an aero mechanical conveyor with a challenging product, it’s crucial to implement controlled feeding. This technique ensures that the material is consistently introduced into the conveyor. If a product is especially troublesome to transport, it might compact or cake in the hopper, leading to irregular entry into the conveyor and, consequently, inaccurate conveyance. To address this issue, discharge aids can be installed to facilitate smoother material flow.

The following table showcases the standard throughput rates that can be expected when using an aero mechanical conveyor for material transport.

Other Conveying Options

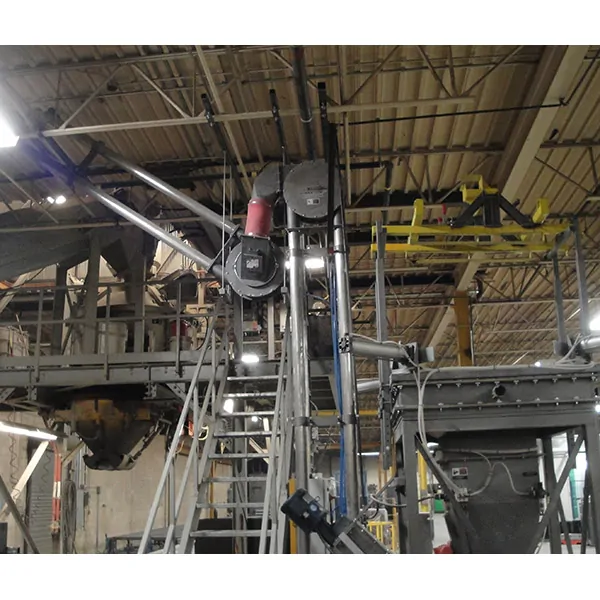

If an aero mechanical conveyor doesn’t suit your material conveyance needs, there are various alternative conveyor belt systems available. Depending on the specific requirements of your application, these alternatives might include the ultra-heavy-duty structural drag chain conveyor belt system, heavy-duty tubular drag chain belt conveyor system, tubular cable drag conveyors, or flexible screw conveyor.

Do You Have More Questions?

With over 40 years of experience in the conveyor solutions sector, Spiroflow is well-equipped to solve a variety of challenges with our conveyor belts and other equipment. If you’re facing any issues, chances are we have the solution you need. Reach out to us for assistance. Interested in exploring more conveyor belt solutions? Discover our complete range of products by visiting Spiroflow’s website today, including the flexible screw conveyor and other industrial conveyor systems!