For over a decade, Excelso Coffee and Tea, located in Norcross, GA, has consistently relied on a Spiroflow AMC (Aero-Mechanical Conveyor) for its manufacturing of flavored coffee. Impressively, the Spiroflow aero-mechanical conveyor has 14 years of Sterling service for this company as a proven track record without needing any part replacements. Excelso, known for customizing condiments and coffee for office spaces, vending machines, and markets for private labels, has benefitted greatly from the conveyor’s durability and efficiency.

Excelso’s Journey with Advanced Conveyor Technologies

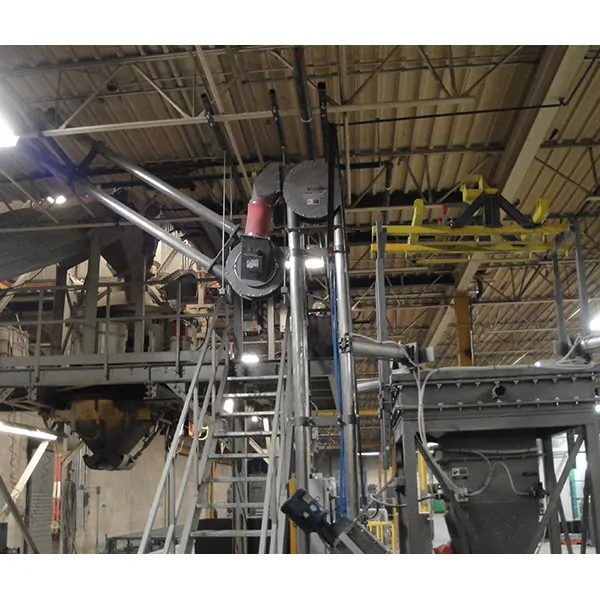

The Model PC3 of our Aero-Mechanical Conveyor, a standout example of conveyor belt solutions, was carefully constructed and installed in Excelso’s production plant in 1994 by our team. Functioning as a vital part of their industrial conveyor systems, this AMC operates intermittently for 8 hours a day, five days a week. It efficiently transports flavored coffee from a blender directly to a hopper for storage. It is a crucial step in preparing the product for packing into bags or coffee pouches. Our conveyor solutions, including this belt conveyor system, demonstrate the innovation and reliability offered by leading conveyor systems manufacturers.

Unprecedented Durability – A Testament to Excelso’s Aero-Mechanical System Maintenance

“When Excelso called and said they required a wire rope replacement for their Aero-Mechanical System, it happened for the first time in 14 years. We were amazed at the life of the rope”, comments Mathias J. Lee, our VP-Sales. “Normally, we expect these ropes to be replaced every 5 to 7 years, depending on the application. What’s equally phenomenal is the fact that no other part has been required to be replaced for the machine. This is as much a tribute to Excelso’s operation and care of their equipment as it is a testament to the robust construction of our Aero-Mechanical Conveyors”, Mathias Lee concludes.

From Local Roastery to National Network

Excelso Coffee and Tea, a major player in the coffee industry, roasts and processes over 2 million lbs of coffee annually, translating into a diverse array of blends. On average, this amounts to about 10,000 lbs daily, fueling approximately 3 million cups of coffee every working day. Through its affiliate, Atlanta Coffee Time, Excelso serves the bustling Atlanta, Georgia, metropolitan area, delivering coffee to offices and strategically placed vending machines.

Beyond local reach, Excelso also collaborates with partners in over 35 states across the USA, offering custom packaging for private-label brands. These partnerships extend Excelso’s conveyor belt solutions and flexible screw conveyor technologies, enhancing their distribution network. By leveraging their industrial conveyor systems and conveyor technologies, these companies mirror Excelso’s successful model, catering to office workers and vending machine operators nationwide.

Excelso’s Strategic Selection of the Spiroflow AMC

Allan Shaw, Vice President of Excelso Coffee and Tea Company, reflects on the company’s decision-making process when choosing their conveying system. After a comprehensive evaluation of numerous suppliers and conveyor system types, Excelso settled on the Spiroflow AMC. Shaw explains, “We mainly selected Spiroflow because of their years of experience and record for excellent after-sales support. We also needed a totally enclosed system that is dust-free and wouldn’t alter the integrity of the flavored coffee. The AMC seemed to be the perfect fit.” This decision was influenced by the need for a solution that maintained the quality of their flavored coffee while benefiting from reliable after-sales service.

Advanced Conveyor Solutions for Flawless Coffee Handling

The Spiroflow Model PC3 Aero-Mechanical Conveyor has a key part at Excelso, adeptly handling the transfer of flavored coffee directly from the blender to a hopper for storing and eventual packing. This essential part of Excelso’s belt conveyor system boasts 3-inch diameter conveyor belts, making it an efficient and dust-free solution for conveyor belt systems in coffee processing.

With its stainless steel construction, it is a strategic choice to reduce the risk of taste contamination between batches, meeting the needs of industrial conveyor systems. Additionally, the AMC is equipped for easy cleaning, featuring a water valve on the top and the drain at the bottom, aligning with the advanced standards of conveyor technologies. Allan Shaw points out that in Excelso’s operation, the AMC is virtually self-cleaning. Its design is a testament to the expertise of conveyor manufacturers in meeting the exacting hygiene requirements of Excelso.

Versatile and Innovative Conveyor System

One of the most notable attributes of this flexible screw conveyor system is its ability to transfer entire batches of material. It can operate efficiently at any angle from 0° to 90°, a feature not commonly found in traditional conveyor belt systems. At Excelso, the AMC is 30 feet long and operates at a 45-degree angle, showcasing the adaptability and innovation of conveyor solutions provided by leading conveyor systems manufacturers.

Exploring the Excelso Coffee Flavoring Operation

Excelso’s coffee flavoring process involves three key components – the Spiroflow AMC, a Vee-Ribbon Blender, and a Storage Hopper. The Vee-Ribbon Blender, like the AMC, is made of stainless steel to prevent any flavor carry-over from previous batches and is designed to be air-tight. This blender is fully automated and operated by computer.

During the flavoring stage, flavor syrup is gradually introduced into the rotating blender in a light, aerated mist, covering about two to three percent of the coffee’s surface area. After the syrup addition, the blender continues to rotate for several minutes, ensuring the flavoring is evenly distributed throughout the coffee. Following this step, a manually controlled hatch at the blender’s base is opened, allowing the flavored coffee to flow into the AMC. The AMC then transports the coffee to a storage hopper through a combination of a slide gate and a flexible hose.

Excelso runs this flavoring operation in a single eight-hour shift, five days a week, efficiently managing this part of their plant. “We usually run 12 to 20 batches in a 4 to 5 hour run time,” confirms Shaw. “Each batch takes from 15 to 20 minutes. The rest of the time, we clean the blender and other equipment to purge it of any residual flavor. This is extremely important to maintain the precise flavor of each batch.”

More About Excelso Coffee and Tea

Excelso Coffee and Tea, established in 1977, sources its coffee beans globally, primarily from Central and Latin America. Colombian coffee makes up 20% of Excelso’s usage. They specialize in custom blending and daily roasting of premium coffees using 100% Arabica beans. Other beans are sourced from over 100 locations, mainly in Central or South America and even from Hawaii. Shaw points out, “Trees don’t produce the same bean each time,” emphasizing the need for continuous core sample inspections to ensure consistency in bean size and color. This meticulous process is crucial because one defective bean can spoil 100 lbs of coffee. The processing of coffee beans begins with the removal of the cherry encasing them, typically using a wet process at the origin. This involves soaking the beans in water for about 24 hours, a critical step as improperly soaked or dried beans can sour.

Precision Roasting and Flavoring

At Excelso, unflavored beans are roasted in large, computerized roasters, each programmed for specific roasts. The Aero-Mechanical Conveyor (AMC) plays a vital role in the preparation of flavored coffee, which is blended in a Vee-Ribbon blender with syrup-type flavoring added. Shaw asserts, “We provide our customers with the highest quality coffee at the best possible price while delivering excellent service.” He emphasizes their commitment to using only top-notch equipment, modern procedures, and prioritizing quality control. Shaw adds, “The AMC is a dust-tight, well-designed system that is virtually self-cleaning. We have been extremely pleased with its performance in getting the flavored coffee to the storage hopper for final packaging in the quantities customers require.”

How the AMC works

The Spiroflow Aero-Mechanical Conveyor (AMC) features a unique design consisting of a continuous loop of wire rope with evenly spaced polyurethane discs. These discs move rapidly within parallel steel tubes, propelled by specifically designed sprockets at each end. One sprocket drives the rope and discs, while the other maintains the rope’s tension. Tube clamps provide support to the conveyor. This high-speed movement of the rope assembly generates a matching air stream velocity. As flavored coffee is introduced into this stream, it is efficiently transported to the storage hopper, where it is ejected through centrifugal force.

The Spiroflow AMC’s Unique Conveying Capabilities

A standout aspect of the Spiroflow AMC is its versatility in conveying materials. It can operate at any angle from 0° to 90° and reach heights exceeding 60 feet, all without sacrificing capacity. This adaptability allows for a variety of system layouts to maximize floor space, including straight-line, ‘L,’ or ‘Z’ configurations.

Commonly known as a “rope and disc conveyor,” the Spiroflow AMC is highly effective for moving materials up to 5/8 inch in diameter at speeds reaching 120 tons per hour. Users benefit from complete ingredient transfer, low energy consumption, dust-free and gentle material handling, minimal product degradation, and consistent mixture quality during transport.

Spiroflow Aero-Mechanical Conveyor – 14 Years of Sterling Service and Many More to Come

Excelso Coffee and Tea’s utilization of the Spiroflow Aero-Mechanical Conveyor (AMC) stands as a testament to the system’s exceptional efficiency, versatility, and reliability in handling coffee processing demands. The AMC’s innovative design and adaptability in system layouts, combined with its capacity to transport materials swiftly and gently, make it an ideal solution for businesses looking to optimize their operations. Excelso’s success story with the AMC highlights the value of investing in high-quality, advanced conveying technology.For businesses seeking to enhance their material handling processes with similar efficiency and precision, exploring Spiroflow’s range of conveyor solutions is a step toward achieving operational excellence. Contact Spiroflow today to discover how our conveyor systems can revolutionize your material handling needs.