Looking for the right conveyor for your coffee product? When it comes to conveying coffee and conveyor choices, remember that coffee beans are delicate and breakable. Keep in mind that the conveyor technologies you are considering should maintain the flavor, aroma, and quality of the coffee throughout the transportation process.

Manufacturers and roasters are moving away from using traditional, open bucket elevators and belt conveyors for moving ground coffee and coffee beans due to both hygienic and layout challenges. Instead, coffee producers are opting for more efficient, hygienic, totally enclosed, and flexible conveying systems.

Conveying Coffee and Conveyor Choices in a Nutshell

Enclosed, hygienic coffee conveyor options include aeromechanical conveyors, flexible screw conveyors, and tubular cable drag conveyors. Still, which of them is the best for your coffee product? For a more refined choice, consider the following aspects:

- The type of coffee product you wish to convey. Different conveyors may suit whole beans, ground coffee, or specialty blends.

- End customer requirements. Evaluate whether you are serving commercial or specialty markets. Consider the importance of whole bean breakage for your customer base.

- Operational needs. Pay attention to aspects like energy efficiency and the impact of the conveyor system on operational dynamics.

- Budget constraints. Identify a conveyor that provides optimal service without overshooting your financial limits.

- Facility layout. Your available space and configuration will also influence your conveyor choice, ensuring the chosen system fits seamlessly into your production line.

Conveying coffee involves not only moving the product from one point to another but also ensuring the preservation of its delicate aromas and subtle flavors. That’s why making the right choice and considering all aspects is crucial.

Coffee Conveying Considerations By Product

Green unroasted beans, roasted whole beans, ground coffee, and coffee mixes all come with characteristics and challenges that must be considered when selecting the right conveying system.

Green, Unroasted, and Roasted Whole Beans

Unroasted, or green, coffee beans are very fragile in their raw state. A gentle conveyor that minimizes bumping, twisting, and grinding will be ideal to protect the beans from breakage. Broken beans mean waste and wasted dollars early in the coffee production process unless the beans can be separated and then delivered as a final ground product. Additionally, the conveyor will need to be constructed to hold up to the abrasive wear of processing whole beans.

Like green beans, roasted whole coffee beans are very fragile and thus must be processed gently to avoid degradation and breakage of the roasted beans. Additionally, freshly roasted beans need to be processed quickly and protected as much as possible from the environment surrounding the conveying machinery to preserve freshness and flavor in the end product.

Ground Coffee and Mixes

Ground coffee is hygroscopic (easily absorbs moisture) in nature and is thus prone to clumping. Additionally, dusting and dust control are of utmost importance when working with ground coffee or coffee mixes due to their combustible properties and for operator environment safety. For ground coffee, maintaining the consistency and size of the coffee grinds is also essential for brewing a good final product.

For coffee mixes, blend integrity can be maintained by using a conveyor that constantly re-mixes the coffee product and prevents separation. Additionally, conveying systems processing different types of flavored mixes or coffees may need to be frequently changed out and quickly and thoroughly cleaned between changes to prevent flavor cross-contamination.

Comparing Totally-Enclosed Coffee Conveyor Options

Choosing the right conveyor is important for maintaining the integrity and quality of the coffee during transportation. The right selection ensures minimal damage and contamination to the coffee, preserving its delicate flavors and aromas. A well-informed choice between the various conveyor options available optimizes the overall efficiency and productivity of the coffee production line.

Flexible Screw Conveyors

Flexible screw conveyors use a spiral or auger inside of an enclosed tube to convey the product up the tube at any angle, including around slight bends. These conveyors are low-maintenance and low-cost solutions. A flexible screw conveyor is ideal for maintaining continuous blends due to the constant remixing of the spiral as the product is conveyed. Thus, the flexible screw conveyor may be an option for coffee granules or mixes.

However, the spiral action can be aggressive and may not be the most suitable solution for conveying friable coffee beans. That being said, for some applications, the flexible screw conveyor may still be a good choice due to the unique requirements. Additionally, many manufacturers offer different types of spirals to best suit your applications.

Screw conveyors may also pose limitations when complex layouts with multiple planes are necessary due to the simple linear nature of their design. Thankfully, other conveying options provide more flexibility, as discussed below, where the layout is a challenge.

Aeromechanical Conveyors

Aeromechanical conveyors operate using evenly spaced discs traveling at speed, which creates an air stream to convey the coffee along with the discs. Totally-enclosed aeromechanical conveyor belt systems are a good option for conveying ground coffee due to their dust-free operation and enclosed design protecting the product from outside moisture.

The aeromechanical conveyors’ stainless steel construction and easy-to-clean features help to reduce flavor cross-contamination if used for different batches of coffee. The aeromechanical conveyor technologies offer fast and efficient conveying for any product, using relatively minimal horsepower.

However, due to the high speeds at which aeromechanical conveyors do run, there is a risk of product degradation and material breakage for friable whole beans, especially at angles or bends in the conveyor layout. Additionally, the introduction of oxygen or air into a product can cause the product to degrade more quickly. As with any conveying solution, running the coffee product through the conveyor in a test lab to understand the operation and end product condition will be essential.

You can also read our Excelso Coffee aeromechanical case study before you decide.

Tubular Cable Drag Conveyors – Best Overall

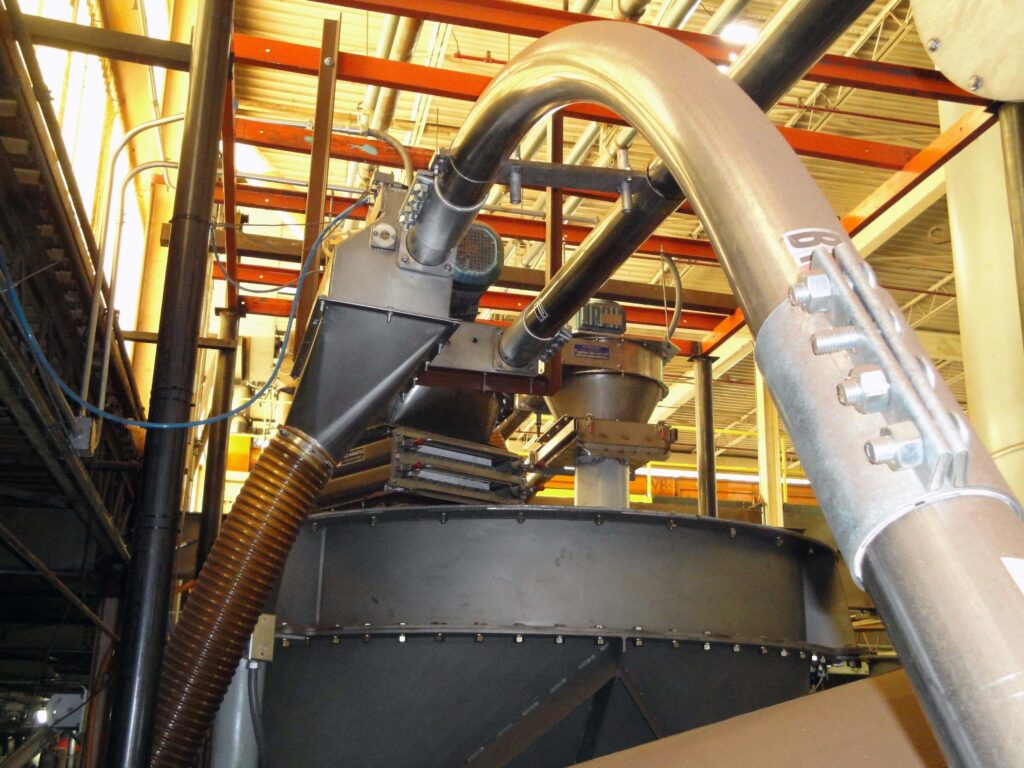

Tubular cable drag conveyors use evenly spaced FDA-accepted polyurethane discs attached to a stainless steel cable to gently drag the product along inside an enclosed tube. Cable drag conveyors are quickly becoming the conveyor of choice for coffee processors due to the minimization of product degradation being a top priority for whole beans.

Cable drag conveyors offer a high throughput of 10s of 1000s of pounds per hour at lower and more steady speeds (vs. the aeromechanical or pneumatic conveying options), which prevents product degradation of friable whole beans. In addition, tubular cable drag conveyors are extremely versatile from a layout perspective and can be used to pick up material from several different sources and transport it over long, complex routes to several different destinations.

Enclosed tubular cable drag conveyors also have the advantage of being hygienic and easy to clean when equipped with clean-in-place dry and wet wash options. Automatic rope tensioning can extend cable life to reduce the risk of downtime and maintenance costs. While these conveyors can represent a significant capital investment, the payback and return on investment can occur very quickly when considering the minimal downtime, ability to run multiple coffee product types on the same machinery, and low maintenance requirements.

These factors can make Tubular Drag Conveyors an ideal choice for manufacturers needing to convey both whole bean and ground coffee. Before you make the final decision, read our Eight O’Clock coffee tubular drag conveyor case study.

Use the Test Lab Facility

Finding conveyor manufacturers that offer test lab facilities is essential for figuring out which industrial conveyor systems are best for your needs. Our engineers always recommend testing your coffee product to mimic your facility’s conditions and selected equipment before purchasing. Contact Spiroflow’s engineers to set up a materials test for your application.

Choose the Right Conveyor Systems Manufacturers

Selecting the perfect conveyor belts is crucial, and Spiroflow is here to guide you every step of the way. Whether you need conveyor belt solutions for conveying delicate specialty blends or any variety of beans, our range of conveyor belt systems is designed to meet your unique needs. Don’t compromise on quality – choose Spiroflow for innovative and efficient conveyor solutions that preserve the integrity and flavor of your coffee. Contact us today, and let’s explore the ideal conveyor choices for your coffee products together.