All About Conveying Coffee and Conveyor Choices

Looking for the right conveyor for your coffee product? When it comes to conveying coffee and conveyor choices, remember that coffee beans are delicate and breakable. Keep in mind that the conveyor technologies you are considering should maintain the flavor, aroma, and quality of the coffee throughout the transportation process. Manufacturers and roasters are moving […]

Tubular Drag Conveyors: How do they work?

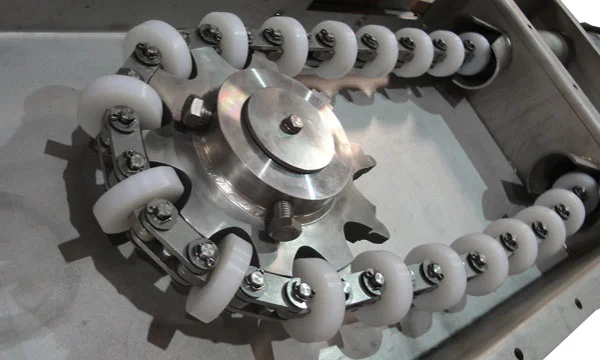

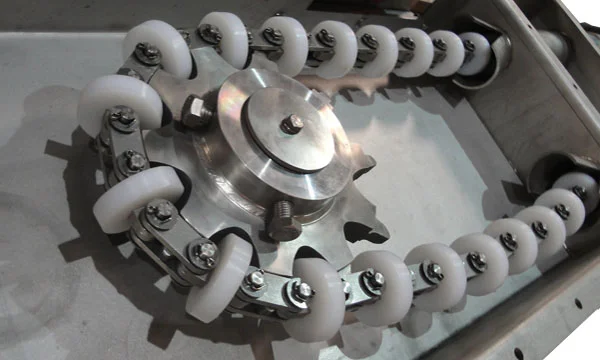

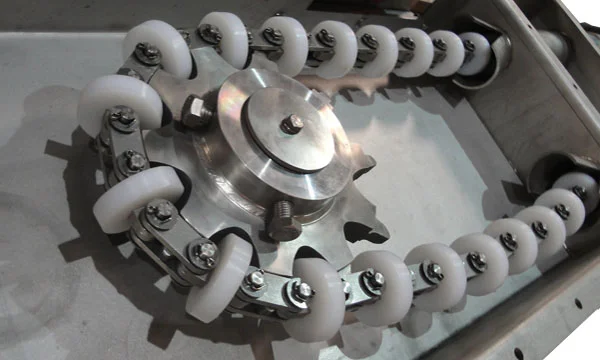

Cablevey conveyors are designed for gentle material handling and for conveying in multiple planes – but how does a tubular drag conveyor work? It works by dragging product gently between two polyethylene discs inside a tube the conveyor with either a cable or a chain. A continuous loop of cable or chain with discs spaced […]

Spiroflow Announces Heavy-duty Drag Chain Conveyor for the Food Industry

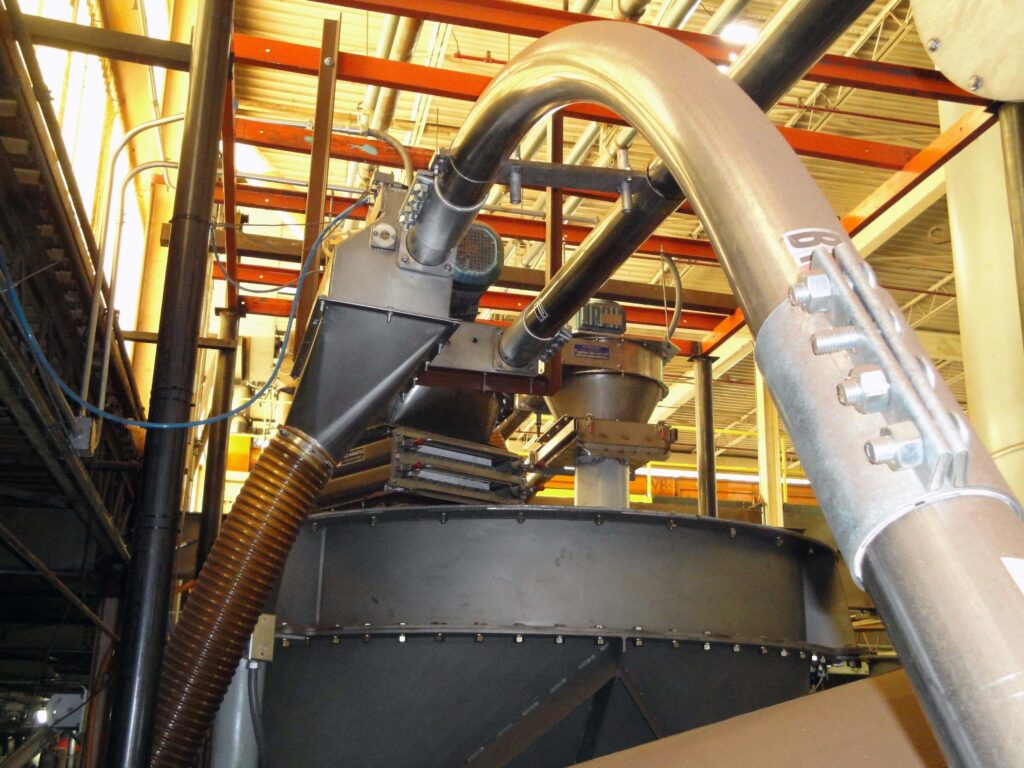

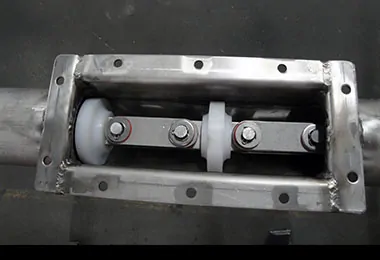

In response to the ever-increasing needs of the food industry, Spiroflow has launched the new Chainflow chain drag conveyor. The hygienic heavy-duty, totally enclosed, dust-free chain drag conveyor economically conveys dry powders and granules particularly fragile materials such as coffee beans, cereals, specialty breakfast cereals, nuts, dried fruit, grains, dry soup mix, candy, small cookies, […]

Structural Drag Chain Conveyor Problems: Keeping It Moving

Structural drag chain conveyor problems happen, but they are avoidable. I understand why you’re wondering about these conveyors. They are an expensive addition to any process, and you want to make sure you’re getting your money’s worth. This article is about helping you keep the conveyor running.

Spiroflow has been around for more than 45 years. Our team members take pride in assisting customers with their dry bulk solids and powder processing needs. This ranges from providing a simple hopper to a complete bulk material handling system. Our work isn’t done when the equipment is shipped. We want to make sure everything works well and as expected.

Best Structural Drag Chain Conveyor Manufacturers (Reviews/Ratings)

Structural drag chain conveyor manufacturers want their products to be ultra heavy-duty problem solvers for the dry bulk solids and powder processing industry.

Materials Best Conveyed by Drag Chain Conveyors

What are the best materials for drag chain conveyors? Running the proper materials decreases down time and increases productivity, because the conveyor is operating at its full potential. We’ll talk more about that in this blog.

There are two types of drag chain conveyors out there – structural and non-structural. At Spiroflow we manufacture both. In order to keep things simple, we will only talk about heavy-duty non-structural drag chain conveyors such as our Chainflow conveyor. We talk about ultra-heavy duty structural drag conveyors in this post.

Overcoming Drag Chain Conveyor Problems and Ensure Smooth Operations

A tubular drag chain conveyor can be an important part of a process. If they’re not running like they’re supposed to, or not at all, then they’re not doing anyone any good. At Spiroflow, we’ve been in the dry bulk material handling industry for more than 45 years and we are proud of our work and our conveyors. We want our conveyors to run well, just like you do. That’s why we are writing about keeping your conveyors moving.

How Much Does A Tubular Drag Chain Conveyor Cost?

How much does a tubular drag chain conveyor cost? We get that question on a regular basis because we’ve been manufacturing these conveyors for customers around the world for years. It’s a great question too because the cost of this type of conveyor can vary quite widely depending on a number of factors. There isn’t a simple answer about the cost because it depends on your individual situation. The material you’re conveying and the requirements of your particular application impact the price. In this article, we will share all the elements that go into designing a drag chain conveyor so you can understand the variables for yourself.

Cable Drag vs. Drag Chain Conveyors

Which drag conveyors are best? Should I go with a tubular chain drag conveyor or a tubular cable drag conveyor? If those questions are on your mind, we can help you out. At Spiroflow, we have more than 45 years of experience in the dry bulk material handling industry and we make both types of drag conveyors.

Sometimes life has to be a Drag!

When it comes to conveyors for dry bulk solids, whether in powder, granule, flake, pellet, lump or whatever form and whether in bulk quantities or as minor ingredients, Spiroflow aim to offer the best solution. We have never believed in the ‘one size fits all’ philosophy. Accordingly, as we have expanded our horizons, we have developed our conveying ranges to meet the new challenges whether organically, by strategic acquisitions or through joint ventures. So, today, we are offer four types of conveyors.